Technologies to Decarbonise the Marine Industry: Maritime shipping is a pillar of our modern worldwide economy, involved in 80 to 90% of international trade. Ships transport everything from raw material to industrial products, goods, feedlots, and transformed food. Despite this omnipresence, maritime shipping “only” produces 3 to 4% of global greenhouse gas emissions (GHG) compared to about 15% for road transportation.

Yet, the general public associates the marine industry with dirty pollution, probably because it only hits the news after a catastrophic oil spill. Or through eye-catching headlines such as “Shipping produces more carbon emissions than most countries” or “If the maritime industry were a country, it would be the 6th largest CO2 emitter worldwide”. Following the Paris agreement on climate, there has been a strong push for the marine industry to reduce both its pollutant emissions (sulphur dioxides (SOx), nitrogen oxides (NOx), particulates) and its greenhouse gas emissions.

The International Maritime Organisation (IMO) has established a 3-step strategy to decarbonise the marine industry:

- New ships must be designed to be cleaner (implementation of further phases of the energy efficiency design index (EEDI)).

- Short—and long-term targets on average GHG emissions: reduce CO2 emissions (per load handling) by at least 40% in 2030 and pursue efforts towards 70% in 2050, compared to 2008 levels.

- Short—and long-term targets on peak international shipping GHG emissions: reduce the total annual GHG emissions by at least 50% by 2050 compared to 2008.

In this race for a green image, a new sort of competition has started involving technology development, business and economy strategy, media coverage, and political argumentations. All actors in the marine industry must be seen as busy developing disruptive approaches that comply with future policies and are financially viable. Several companies are already working on reaching a greener image, such as Maersk, which has announced its intention to become net-zero carbon by 2050, with carbon neutral vessels on the sea by 2030.

The present article reviews various technologies that the marine industry is currently exploring to reduce CO2 emissions. For each option, we will discuss the GHG reduction potential, technical feasibility, and existing demonstrator. We will also try to evaluate the economic viability of such technologies and their probability of development in the future.

1 Status – Some Orders of Magnitude

Nearly 90% of international trade uses maritime transport at some point, be it to import raw materials or export finished products. Despite this large implication, maritime transport’s GHG footprint is “only” about 3%.

Currently, there are more than 53,000 ships for international shipping of goods and passengers. Altogether, they represent more than 500 GW of engine power output. As an order of comparison, 500 GW is equivalent to 10 million entry-level Volkswagen Polo cars. At first glance, this might not seem so impressive, but shipping boats run 24/7, and are always quite close to rated power. On the other hand, an average car is on the road for only about 300 hours per year and rarely reaches rated power. Therefore, A maritime shipping engine runs for about 30 times longer than a car engine each year, so the 53,000 ships are arguably equivalent to 300 million entry-level cars. Knowing that there are approximately 1.4 billion cars in the world today, the impact of marine transportation cannot be neglected.

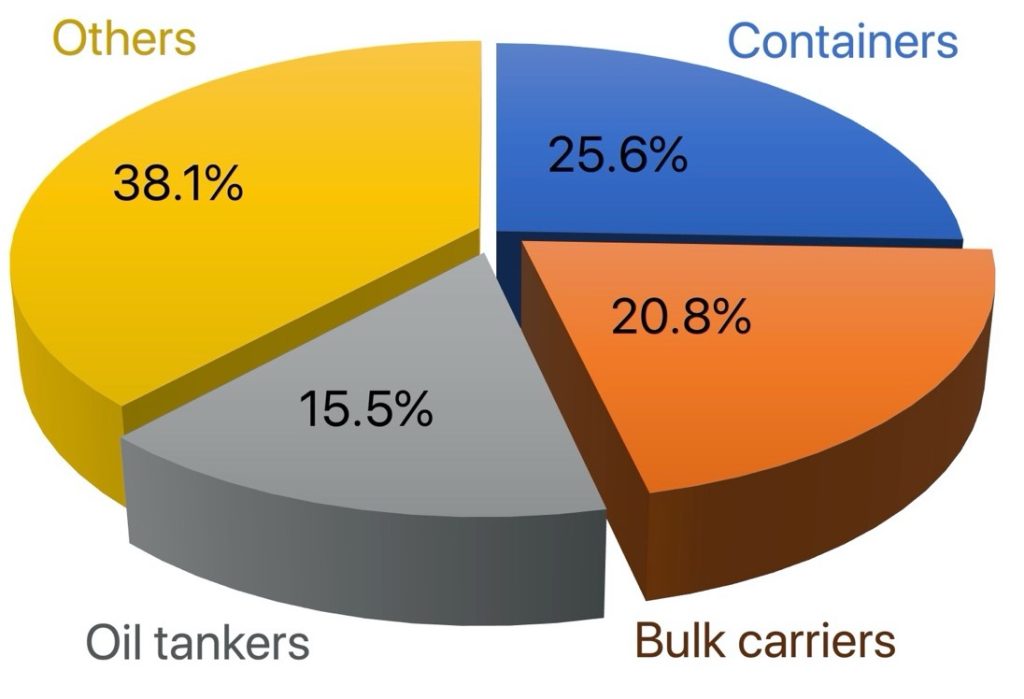

Shipping emissions depend on the length of journeys (explaining why container ships and oil tankers are considerable pollution sources and GHG contributors), but also on fuels and efficiency. Globally, CO2 emissions (Fig. 1) are mainly due to container ships, bulk carriers, and oil tankers (but these three ship classes accounted for 84% of total shipping capacity).

Figure 1- Share of CO2 emissions by ship class.

When comparing transportation modes in CO2 emitted per tonne-km, maritime shipping is much cleaner than other modes. As detailed CO2 emissions vary with ship size and payload, only average numbers are comparable. For a large ship, the order of magnitude is about 5g/tonne-km (with best-in-class delivering less than 2g/ton-km), while it is about 50g/tonne-km for trucking and about 20g/tonne-km for the railway.

Of course, the tonnage of large container ships is the main advantage when comparing per tonne transported, but it is not the only one. Large engines used in marine are much more efficient than their on-road homologue for two reasons:

- Marine engines are optimised to run on a single operating point while trucks and cars need to cope with various engine loads and speeds;

- Up until recently, there was no real legislation on marine pollutant emissions, so engine design only purely targeted low fuel consumption, with low CO2 emissions as a by-product. Introduction of pollution control devices will hurt CO2 emissions.

Contrary to the automotive and truck industries that have faced pollutant emission legislation for many years, such constraints are relatively new for the maritime industry. However, because various technologies have been progressively introduced in road transportation, the general public and politicians assume that a broad range of options, such as new fuel sources, engine technologies, and electric propulsion, are ready to be introduced. Each option offers decarbonisation and green credit but also involves reliability questions and financial costs. Furthermore, boats’ lifespan is much longer than trucks and cars, meaning a wrong choice would have long-lasting consequences.

The challenge for shipbuilders and large carriers is to evaluate each option and balance the technological cost with other strategic options such as slow steaming (slowing down the ship to reduce fuel consumption at the expense of longer delivery times). The large variety in ship design and end-use (cargo, tanker, ferry) implies different ways to operate with multiple engine technologies and compliance with emission legislation. Consequently, there is no unique solution for maritime decarbonisation; rather, there is a range of solutions to combine smartly.

2 Technologies to Decarbonise the Marine Industry: Impact of Fuels

For more than 60 years, heavy fuel oil (HFO) has been the dominant marine fuel. Viscous, dirty, widely available, and inexpensive, HFO supported the maritime shipping business model. If HFO is an awful fuel to burn, it is essential to keep in mind that it is so cheap and readily available because it is the by-product of the other crude-based industries that have no other use.

Pollution and climate concerns impose an evolution of marine fuels towards cleaner energy sources, renewable if possible. Yet, changing fuel creates several challenges, not only technical or economic but also from the distribution point of view.

2.1 Liquefied Natural Gas (LNG)

One potential fuel to comply with SOx, NOx and CO2 reduction is LNG (natural gas that has been liquefied to optimise storage). The first dedicated LNG vessel was built in 2000, and about 120 commercially-running LNG vessels are today. They mainly operate in Europe and North America, where emissions legislation is the most stringent.

LNG is generally cheaper than other alternative marine fuels. Still, its price fluctuates a lot, and it requires a specific infrastructure, increasing its cost on international trade routes where it has not yet been widely adopted. Only vessels running most of their time in Emission Controlled Area (ECA) zones get an economic advantage to use LNG, while there is no strong incentive in other parts of the world.

From a composition point of view, LNG contains less carbon per unit of energy than conventional marine fuels. Less carbon content means less CO2 emissions, with a theoretical gain of about 20% compared to HFO. However, because LNG is mainly methane, there are other GHG emissions to consider. A recent detailed analysis published by ICCT (International Council on Clean Transportation) suggests that the LNG benefit on GHG emissions is much smaller because of:

- The upstream supply chain emissions include resource extraction, liquefaction, and transportation.

- The related emissions of methane, a gas with a GHG potential far higher than CO2, are due to leakage and unburnt fuel due to incomplete combustion.

The supply chain is out of control in the shipping industry, and leakage can be minimised so that the technically challenging reduction in unburnt fuel is the critical axis for improvement. The mechanism is well-understood: a part of the fuel is pushed into the smallest crevices of the combustion chamber (head gasket, piston rings, valve seats) during the compression stroke, escaping the combustion. Additionally, wall heat losses prevent the flame from touching the walls, leaving a thin layer of unburnt fuel. The same phenomenon is responsible for unburnt hydrocarbon emissions in road transport applications. Still, it becomes more critical when methane is the fuel as it is a greenhouse gas, impeding the positive impact of LNG on climate change.

A generalisation of LNG impact on GHG emissions is made even more complicated by the large variety in engine technologies used to propel ships:

- Lean-Burn Spark-Ignition (LBSI) engines, usually four-stroke, medium speed

- Low-Pressure injection Dual-Fuel (LPDF) engines that can be 4-stroke medium-speed or 2-stroke low-speed

- High-Pressure injection Dual-Fuel (HPDF) engines that are 2-stroke low-speed

- Steam turbines

- Gas turbines

Each setup has a different operating strategy, efficiency, pollutant emission and cost. Generally speaking, Lean-Burn approaches with Low-Pressure injection are cheaper and more efficient but release more unburnt methane than the High-pressure injection counterparts.

There is also a compromise between NOx reduction and methane slip because a higher fuel conversion requires a higher combustion temperature, increasing NOx emissions. Therefore, without any additional after-treatment device for NOx, reducing GHG emissions with LNG is restricted by NOx emissions limits.

Whatever the engine technology and operating strategy, LNG is a much cleaner fuel than HFO in terms of pollutant emissions. SOx and particulate emissions can be decreased by 90 to 99% compared to HFO, while NOx emissions can also be reduced mainly by more than 70% and up to 90% by leaning the mixture (at the expense of methane emissions).

2.2 Biofuels and E-Fuels

If crude oil could be replaced by “recycled” CO2, net CO2 emissions could be drastically reduced. This simple idea is the foundation for the use of biofuels and e-fuels. Biofuels recycle CO2 through plant growth, while e-fuels use excess renewable electricity. Furthermore, such fuels are all synthetic; they contain negligible amounts of sulphur, simultaneously solving the SOx emission issue.

Depending on raw material and the synthesis process, some advanced biofuels can reduce CO2 emission by up to 90% (especially using waste oils). Biofuels can be used pure or blended with conventional fuels, allowing their distribution through the existing infrastructure and compatibility with existing engines.

Today, are available relatively large quantities of the first generation of biofuels, such as Fatty Acid Methyl Ester (FAME), bio-ethanol, Hydrotreated Vegetable Oil (HVO), Straight Vegetable Oil (SVO), Di-Methyl-Ether (DME), or Fischer-Tropsch Diesel. Nevertheless, the use of biofuels is internationally restricted because of trade-offs in utilising resources that involve human essentials such as food and water. This explains the interest in waste oils because:

- It is not conflicting with human welfare.

- It is recycling an otherwise discarded by-product.

- It is available in large quantities.

In the absence of incentive or clear policies, biofuels remain relatively expensive compared to their fossil counterparts (about twice the price). For instance, usage costs can ramp up due to maintenance costs induced by corrosion issues or lubricant degradation.

E-Fuels are the next step in synthetic fuels, theoretically allowing the tailoring of fuel to requirements and suppressing raw material handling. Underlying benefits are:

- No conflict with agriculture land use or food availability

- No dependence of the end fuel on the used raw materials

- Reliance on renewable electricity that can be cleanly transported from “harvesting” areas to the fuel production and usage area

By using excess renewable electricity when production exceeds demand, e-fuel production could become a smart way to control electricity networks while producing sustainable fuels at a relatively low cost.

2.3 Methanol

Methanol is a low-carbon-content synthetic fuel that can be produced from renewable sources (mainly biomass) or fossil resources (natural gas or coal). Gains in CO2 emissions are therefore mainly dependent on its production process, while the reduction in SOx emissions is always significant. Methanol is more expensive than conventional fossil fuels and LNG, so its usage depends on incentives or any public image strategy. There are currently multiple ships running on methanol as demonstration exercises.

2.4 Ammonia

Ammonia is a recent development intended to provide a carbon-free hydrogen source without the related safety and handling issues. Its production is similar to e-fuel synthesis minus the introduction of CO2.

Ammonia can be used in combustion engines or fuel cells (see next section). It is still at a very early stage of development for marine applications. Still, five major companies (Imabari, MAN Energy Solutions, Mitsui E&S Machinery, ClassNK, and ITOCHU ENEX) have recently agreed to develop ammonia-fuelled engines for their ships.

3 Technologies to Decarbonise the Marine Industry: Alternative Propulsion Systems

3.1 Hydrogen Fuel Cells

Fuel cells are a promising technology, but there is no clear path to industrialisation today. Yet, a few developmental hydrogen fuel cell ships are already sailing.

The critical advantage of fuel cells is the efficiency with gains of up to 30% compared to Diesel generators and micro gas turbines for the same power output. When running on hydrogen, they also suppress any CO2 emission. Yet, gains in GHG emissions depend on the feedstock used for hydrogen production: electrolysis based on renewable electricity is cleaner than coal gasification, with biomass gasification and natural gas reforming sitting in-between. Orders of magnitude for hydrogen production are 110 equivalent gCO2/kWh for renewable electrolysis versus 1000 equivalent gCO2/kWh for natural gas reforming without Carbon Capture System.

Hydrogen properties introduce specific stumbling blocks. Its low density and safety issues require handling the fuel in liquid form, i.e. at temperatures below -100°C, which introduces specific constraints:

- Infrastructure: Liquid hydrogen storage requires eight times more volume than HFO, limiting retrofit possibilities but also requiring specific port development.

- Safety: cargo shipping must comply with the International Code for Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code). However, the IGC Code does not currently allow the transportation of liquid hydrogen. Changes are slow with Australia and Japan introducing a memorandum permitting bulk shipping of liquid hydrogen.

3.2 Electric Propulsion Systems and Batteries

Electrification is a significant trend of e-mobility across the transportation sector. Electricity can be used on-board ships through shore power connections, supplying auxiliary power when the vessel is in port. This is sometimes referred to as ‘cold ironing’. Energy can also be stored in batteries and restored later at sea, reducing the ship’s CO2 emissions per load handling.

As for hydrogen-based propulsion, the net GHG gains are linked to the electricity production method. Producing electricity from renewable sources such as wind or sun produces very low CO2 emissions, while non-decarbonised electricity sources can negate the benefits.

Some demonstrators are currently testing this technology in the marine industry. For example, the Norwegian Electric Systems company is developing a hybrid engine for ships that combines a conventional internal combustion engine and an electric propulsion system based on lithium-ion batteries. Benefits and costs cannot be evaluated yet as the demonstration is at a very early stage.

3.3 Other Methods of Hybridisation

Several new technologies can help reduce CO2 emissions from shipping, such as wind propulsion assistance, low-resistance hull coatings,…

Wind power includes many options: soft sails, kites, wind turbines, etc. If they lack the power to serve as an independent propulsion method, they can be used to assist in fuel savings.

Wind propulsion is more effective for small ships (< 10 tonnes). As they represent about 20% of world cargo ships, it could still play a significant role in reaching GHG emission targets. Several shipping companies have trialled sails on cargo vessels, but it remains an immature option that requires more safety and reliability developments.

Conversion of wind energy into electricity is also at an early development stage. Implementing wind turbines in the small power range is already used in some vessels to power lighting systems. However, introducing more powerful wind turbines for ship propulsion is more challenging because of the additional safety issues and the need for thermal management.

Several carriers also tested solar assistance, including hybrid sail systems that combine wind and sunlight. Nevertheless, the erosion of solar panels by the salty marine environment is a new topic on which no data are available. Consequently, the potential CO2 savings are difficult to estimate because the real-life efficiency loss with time is unknown.

3.4 Nuclear Marine Propulsion

Due to public perception and political restrictions, nuclear vessel propulsion is unlikely to develop, but from a purely technical point of view, nuclear is a zero-CO2 emission technology.

It can be achieved via a small on-board nuclear plant heating water to raise steam, which drives steam turbines and turbo generators. It has been extensively used for military applications, ranging from warships to submarines and estimations indicate that there are still about 150 naval nuclear reactors in operation. So far, there have only been four commercial nuclear vessels, and only one is still active: the Russian icebreaker Sevmorput.

Nuclear propulsion is highly unpopular due to safety concerns. Its implementation in commercial vessels would require specific training of highly qualified sailors and specific maintenance procedures, which are likely to impede commercial viability.

4 Technologies to Decarbonise the Marine Industry: Internal Combustion Engines

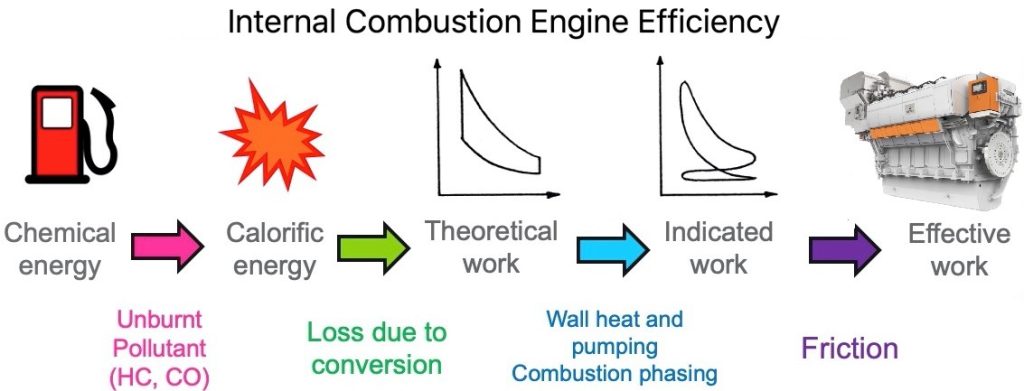

Although new propulsion methods will be introduced, internal combustion engines will remain a significant portion of maritime shipping in the coming decade(s). And despite their higher efficiency than their on-road counterparts, marine engine efficiency improvement still remains (Fig. 2). It will not be a simple technology transfer from on-road applications. Still, some general trends are likely to be reproduced. Future engines will undoubtedly be more complex, increasing maintenance cost and challenging equipment reliability. A vast array of new solutions, such as Common Rail injection systems, 2-stage turbocharging, Variable Valve Train or heat recovery, could be introduced to save fuel and comply with pollutant emission legislations. Yet, the actual operating conditions will affect their benefits, so specialisation concerning end-use is expected.

Figure 2- Global engine efficiency from the energy contained in the fuel toward useful work to move a ship

4.1 Combustion Phasing

Combustion speed and timing are critical to the global efficiency (green and blue arrows in Fig 2) of fuel conversion into propulsion capacity. The laws of thermodynamics define a preferred timing for heat release, ideally through an instantaneous fuel conversion. However, actual fuel/air mixing and chemical conversion require a few milliseconds, reducing efficiency. Engine developments, therefore, notably aim to increase the speed of heat release up to limits drawn by safety, engine reliability, and control.

The core components for controlling mixing are the injection system and the turbulence inside the combustion chamber (determined by the chamber design). Increasing injection pressure is a simple way to accelerate fuel/air mixing and, subsequently, combustion. Lower fuel consumption can, therefore, be achieved up to the point where additional energy consumption for fuel pressure creation overcomes combustion benefits. The potential fuel consumption savings of increasing injection pressure are about 3-4 g/kWh.

Yet, injection pressure might also be dictated by pollutant emissions. Higher injection pressure reduces particulate emissions through better fuel/air mixing, but quicker combustion increases NOx emissions. Therefore, the selection of a specific after-treatment approach (see below) might push engine development towards a specific injection pressure strategy.

Modern Common Rail injection systems further allow splitting injections into multiple events, giving additional control on heat release and pollutant emissions. All modern on-road and off-road Diesel engines use this technology to optimise efficiency.

4.2 Peak Firing Pressure

Increasing peak in-cylinder pressure provides efficiency gains but increases failure risks. Such an increase can be related to multiple technological approaches: compression ratio, boosting, and valve strategy. Yet, some marine engines already have peak firing pressures well above those of other vehicles, so it is unclear if a further increase is still worthy.

4.3 Gas Exchange

Engine power is defined by the amount of air and fuel that can be forced into the engine on the rated power operating point. Increasing efficiency and reducing pollutant emissions further emphasise airflow management and might require precise control over a broader set of conditions.

More air can be forced through the engine with turbocharging, which is widely adopted in marine engines. Further refinement with 2-stage turbocharging, including intermediate air cooling between compression stages is gaining interest. Yet, exclusive focus on rated power can lead to setups that inefficiently spool up to these rated conditions or struggle to operate under part-load conditions properly. Consequently, more advances in turbocharging systems such as Variable Geometry Turbine (VGT) that can adapt their operation to the engine demands might have a bright future.

Increasing the pressure of air fed to the engine with a turbocharger is not the only way to increase power output and efficiency. The valve opening strategy, which controls the timing of gas flow, has been kept relatively simple in marine engines. Introducing some variability in the valve opening profile would allow a high-efficiency Miller cycle at part load and a more conventional strategy for rated power. However, experience over the past 20 years in the automotive industry shows that significant gains in efficiency are obtained at the expense of reliability.

Interestingly, such approaches can be combined, as shown by the current development of high boost pressure and Miller cycle at various engine manufacturers. These approaches should significantly increase fuel consumption and CO2 reduction while maintaining or increasing the rated power.

4.4 Waste Heat Recovery

About half the fuel energy released during combustion is lost rather than converted into propulsion work (Fig 2). A large portion is directly lost to the atmosphere through hot exhaust gases, often denoted as waste heat. The rest is mainly lost in the cooling and the lubricant systems.

Waste heat recovery converts such heat into further mechanical work or electricity. Two main approaches are under development:

- Rankine cycle systems rely on heat exchangers in the exhaust line and a two-phase flow operation with specific refrigerant fluids propelling a turbine.

- Electric or hydraulic turbochargers add an electric motor or a hydraulic turbine to a conventional turbocharger. Therefore, exhaust gas energy can be split between the energy required to propel the conventional compressor and excess energy to be recovered.

While most approaches are feasible for any internal combustion engine, hydraulic recovery in turbochargers only targets large engines and is, therefore, more specific to marine applications. The latest version of Mitsui E&S Machinery Turbo Hydraulic System (THS) claims 2% fuel savings.

4.5 Lubrification

Fuel energy conversion into mechanical work includes sliding and rotating contacts, hence friction that increases fuel consumption and CO2 emissions. Lubricants are used to minimise contacts and reduce friction, with a trend towards lower and lower viscosity. Yet, lubricants also have additional roles, such as ensuring part cleanliness or protecting against wear. New fuels and new combustion strategies will change the lubricant operating conditions so that evolution of lubricant technology will be required.

5 Technologies to Decarbonise the Marine Industry: Pollutant emissions and after-treatment

Generally speaking, the best engine efficiency does not correspond with the lowest pollutant emissions. The most obvious example is NOx emissions: the best efficiency requires quick high-pressure combustion, which induces high in-cylinder temperature, while reducing NOx emissions requires low combustion temperature. There will, therefore, always be a trade-off between efficiency and NOx emissions.

NOx emissions can be reduced with alternative methods, such as recirculating burnt gases from the previous combustion or using exhaust after-treatment. Yet, even if this gives more flexibility, it does not suppress the trade-off. Recirculating burnt gases reduces NOx emissions quicker than efficiency, so there is an optimum to find. However, there will be a slight loss in efficiency to accept. Furthermore, recirculating burnt gases negatively influences particulate emissions, requiring further combustion degradation or dealing with an additional after-treatment device.

It is possible to choose a minimal degradation of combustion efficiency and mostly rely on flue gas cleaning to reduce NOx emissions. The most common NOx after-treatment technology is Selective Catalytic Reduction (SCR). A catalytic converter promotes a reduction reaction of NOx by a reducing agent. The reducing agent is generally urea or ammonia blended with water. In marine applications, the standard solution is AUS40, made of 40% urea blended with demineralised water.

SCR is not a simple technology as it relies on heat from exhaust gases to promote catalytic reactions. Therefore, the after-treatment unit needs to be located close enough to the engine, which might prevent easy retrofitting in some cases. SCR is also highly sensitive to catalyst poisoning by sulphur, a critical issue in marine fuels.

In addition to technological complexity and fuel restrictions, SCR also introduces the additional cost of AUS40 consumption. Investing in SCR is only economically viable at high fuel prices. Under cheap fuel circumstances, operators might prefer sacrificing some efficiency to reduce NOx emissions without an SCR system.

Marine after-treatment also includes a control device for particulate matter emissions, called a scrubber. Exhaust gases are forced through an alkaline scrubbing material that neutralises acidity and removes particulate matter. The collected material is stored and disposed of later.

There is current research to expand the realm of scrubbers by coupling them with the carbon capture storage (CCS) method, further reducing the CO2 emissions. Because such a process releases heat, it could be coupled with a heat recovery method to gain power and/or enhance fuel efficiency.

6 Technologies to Decarbonise the Marine Industry: Old recipes: Slow Steaming and Hull Coatings

Not all fuel-saving methods are brand new technologies. Old sayings and recipes still hold: speed, size, beam, draught and length of a boat have a significant influence on fuel consumption and CO2 emission. While these have been used in the past to quantify economic benefits, they might be critical to future GHG emission management.

Large ships tend to be more energy-efficient per freight unit than smaller vessels because when the cargo capacity doubles, the required power only increases by two-thirds. Also, ship speed largely influences fuel consumption, as the required engine power output relates to speed with an exponent of 3 to 4. Slowing down a large ship is a simple way to reduce overall fuel consumption (CO2 emissions) per freight unit.

6.1 Slow Steaming

A 10% reduction in shipping speed is expected to result in a total average emissions reduction of 19%. The slow steaming advantage varies with the shipping category, routes, and duties. The best savings are obtained for vessels on long trade routes.

If slow steaming allows reducing CO2 emissions, it does not without consequences for vessel maintenance and reliability. The change in engine operating conditions gives rise to various problems such as deposits, cleanliness, and corrosion due to low temperatures and poor combustion (when applied to engines not initially designed for this purpose).

Speed reduction is covered via the EEDI and might be encouraged if emission reduction does not reach targets fast enough. Yet, mandatory shipping derating would be very unpopular with cargo owners, as they would have to reduce their turnover.

6.2 Paints and Hull Coatings

Bacteria attached to the underwater surface of ships attract seaweed, mussels, and other marine life. This attached marine life increases the ship’s drag coefficient and, therefore, fuel consumption. It is estimated that slime can add 2% to drag and weed 10%, which translates into 2% of fuel consumption per year.

Paints and hull coatings can reduce skin friction, and research is being done to prevent bacteria from developing on the hull. For many years, tin-based coatings have been used, but they are toxic to the environment, so they have been banned. Today, there are more eco-friendly options, such as epoxy, vinyl ester, and silicone elastomers. Nevertheless, these new materials are relatively expensive.

7 New recipes: Digitalisation

The marine industry has recently deployed digital tools mainly for financial optimisation, safety, and sustainability. Digitalisation also has excellent potential for reducing GHG emissions.

CO2 reduction is possible by optimising cargo capacity, shipping routes and cargo handling in a port. For example, Just-In-Time (JIT) arrival to port minimises time at anchorage, allowing optimisation of travelling speed and CO2 savings.

Nevertheless, digitalisation is developed by independent actors for their benefit without any global optimisation. There is room for more gains if worldwide GHG emission becomes the primary issue to tackle.

8 Perspective

The marine industry needs to urgently reduce its CO2 emissions to align with the global concern for climate change. IMO has set objectives and provides guidelines for marine engine manufacturers and shipping companies. But the marine industry involves many different actors with an extensive range of vessel sizes, technologies, and ways of operating that need to comply with various constraints and policies. A unique solution is unlikely to emerge, but rather, a combination of solutions will need to be developed in parallel.

There is no shortage of technologies to reach such an objective. Still, a careful evaluation of each is required to ensure pollutant and GHG emission reduction at an economically-viable cost. Fuel selection is a real brainteaser with many possible business strategies. Shipping companies must decide between retrofits or massive investments in more advanced technologies for their marine engines. Such decisions must balance short-term operations with long-term planning of future steps as shipbuilding is a long-term investment.

In general, mobility and the global economy are currently at the edge of dramatic changes with many uncertainties and risks. It is time to take risks, invest smartly, be agile, and move quickly. Marine is a relatively risk-averse and very traditional business, and this transformation will be challenging. Only the companies with the best strategies can survive the new order in which green-branding will definitively be a key element.

About the Author

Dr Cecile Pera- Automotive professional recognised and featured many times on LinkedIn as trendy in Automotive, e-mobility and many more. Dr Cecile Pera has more than 8,000 followers and generates original technical and business content with a global visibility of 1.5 million views/year.

You can view her professional website here: www.orovel.net/drcecilepera

To all knowledge

To all knowledge