We look at the Anaerobic Digester Design in South Africa. South Africa’s electricity is produced mainly from coal because it is the most abundant source of energy. It is the most widely used primary source of fuel and contributes to about 77% of the country’s primary energy needs. Coal contributes to greenhouse gas emissions to the atmosphere that leads to global warming.

Fossil fuels contribute to the increase in the concentration of carbon dioxide in the atmosphere, hence alternative energy sources (renewable energy) must be used in the place of fossil fuels. The commercial production of biogas and another alternative renewable energy source such as solar energy, wind energy, hydropower, geothermal will definitely give a drive for the development of the economy.

Energy derived from biogas is used in the form of fuel, heat, and electricity. Biogas is a renewable source of energy derived from biodegradable substrates such as agricultural wastes, animal wastes, domestic wastes, crops and industrial waste. It is produced by anaerobic digestion, which is a biochemical process in the absence of oxygen. The main product of biogas is methane and carbon dioxide.

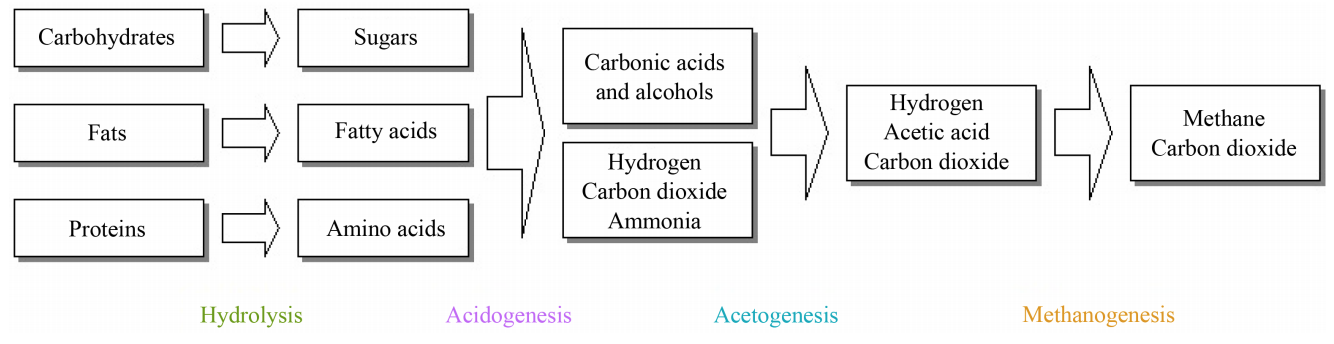

Anaerobic digestion is often considered to be a complex process, the digestion itself is based on a reduction process consisting of a number of biochemical reactions taking place under anoxic conditions. Methane formation in anaerobic digestion involves four different steps: hydrolysis, acidogenesis, acetogenesis, and methanogenesis.

Generally in an anaerobic digestion process, the rate-limiting step can be defined as the step that causes process failure under imposed kinetic stress. In other words, in a context of continuous culture, kinetic stress is defined as the imposition of a constantly reducing value of the solids retention time until it is lower than the limiting value; hence it will result in a washout of the microorganism.

Most researchers report that the rate-limiting step for the complex organic substrate is the hydrolysis step due to the formation of toxic byproducts (complex heterocyclic compounds) or non-desirable volatile fatty acids (VFA) formed during hydrolysis: whereas methanogenesis is the rate-limiting step for easy biodegradable substrates.

The anaerobic digestion process can be divided into two phases as illustrated in Figure 1. The microorganism carrying out the degradation reactions in each of these phases differ widely regarding physiology, nutritional needs, growth kinetics, and sensitivity to the environment. Very often, it is difficult to keep a delicate balance between these two groups: the acid-forming and the methane forming microorganisms, which lead to reactor instability and consequently low methane yield. The two main groups of microorganisms could be physically separated with the intention of making use of the difference in their growth kinetics. In order to accomplish phase separation, several techniques have been employed such as membrane separation, kinetic control, and pH control.

Figure 1: Phase separation of the anaerobic digestion system

This is the first step in the anaerobic digestion process, it involves the enzyme-mediated transformation of insoluble organic materials and higher molecular mass compounds such as lipids, polysaccharides, proteins, fats, nucleic acid etc. into soluble organic materials i.e. to compounds suitable for the use as the source of energy and cell carbon such as monosaccharides, amino acids and other simple organic compounds. This step is carried out by strict anaerobes such as bactericides, clostridia and facultative bacteria such as streptococci etc. This first stage is very important because large organic molecules are simply too large to be directly absorbed and used by microorganisms as a substrate/food source. To accomplish biodegradation, certain microorganisms secrete different types of enzymes, called extracellular enzymes, which “cut” the larger molecules up into smaller pieces that the microorganism can then take into the cell and use as a source of energy and nutrition. Some microorganisms secrete several different enzymes, which allow them to break down different types of organic materials. Other microorganisms are specialised. For example, they secrete enzymes that break down either sugar or protein. Microorganisms that break down different sugars are called saccharolytic, while those that break down proteins are called proteolytic. There are different enzymes for sugars, proteins, fats etc. The rate of decomposition during the hydrolysis stage depends greatly on the nature of the substrate. The transformation of cellulose and hemicellulose generally takes place more slowly than the decomposition of proteins.

The monomers produced in the hydrolytic phase are taken up by different facultative and obligatory anaerobic bacteria and are degraded further into short-chain organic acids such as butyric acids, propanoic acids, acetic acids, alcohols, hydrogen and carbon dioxide. The concentration of hydrogen formed as an intermediate product in this stage influences the type of final product produced during the fermentation process. For example, if the partial pressure of the hydrogen were too high, it would decrease the number of reduced compounds. In general, during this phase, simple sugars, fatty acids and amino acids are converted into organic acids and alcohols.

The products produced in the acidogenic phase are consumed as substrates for the other microorganisms, active in the third phase. In the third phase, also called the acidogenic phase anaerobic oxidation is performed. Products which cannot be directly converted to methane by methanogenic bacteria are converted into methanogenic substrates, volatile fatty acids and alcohols (VFA) are oxidized into methanogenic substrates like acetate, hydrogen and carbon dioxide, VFA with carbon chains longer than one unit are oxidized into acetate and hydrogen. It is important that the organisms which carry out the anaerobic oxidation reactions collaborate with the next group, the methane forming microorganisms; this collaboration depends on the partial pressure of the hydrogen present in the system. Under anaerobic oxidation, protons are used as the final electron acceptors which lead to the production of H2. However, these oxidation reactions can only occur if the partial pressure of hydrogen is low, which explains why the collaboration with the methanogens is very important since they will continuously consume the H2, to produce methane. Hence during this symbiotic relationship inter-species hydrogen transfer occurs.

In the methanogenic phase, the production of methane and carbon dioxide from intermediate products is carried out by methanogenic bacterial under strictly anaerobic conditions. Methanogenesis is a critical step in the entire anaerobic digestion process as it is the slowest biochemical reaction of the process. Methanogenesis is the final stage whereby methanogens bacteria converts hydrogen, acetic acid, and carbon dioxide to methane and carbon dioxide. Equation 1 shows a simplified generic anaerobic digestion.

C6H12O6 ® 3CO2 + 3 CH4 (1)

Figure 2 shows the whole biochemical process.

Figure 2: The key process stages of anaerobic digestion.

The activity of biogas production depends on various parameters that include: temperature, partial pressure, pH, hydraulic retention time, C/N (Carbon to Nitrogen) ratio, pre-treatment of feedstock, a trace of metals (trace elements) and concentration of substrate.

As a guideline, the C/N ration for anaerobic digestion should be around 25-30:1. Should more Carbon be present the biochemical decomposition slows down?

Batch or Continuous configuration

AD can be performed as a batch or a continuous process depending on the substrates being digested and the configuration of the digester. In a batch process, the substrate is added to the digester at the start of the process and sealed for the duration of the retention time (RT). After digestion, biogas is collected and the digester is partially emptied. They are not emptied completely to ensure inoculation of fresh substrate batch with bacteria from the previous batch.

In a continuous digestion process, organic matter is constantly added in stages to the digester on a daily basis. In this case, the end products are constantly removed resulting in constant biogas production. Single or multiple digesters in a sequence may be used.

The selection of biogas digester depends on the dry matter (DM) content of the digested substrate. There are two AD technologies systems: wet digestion which is liquid digestion; when the average DM content of the substrate is less than 15% and dry digestion which is solid digestion; when the DM content of the substrate is more than 15% (usually from 20 to 40%). Wet digestion is applied for substrates like manure and sewage sludge, while dry digestion is applied for solid municipal bio-waste, solid animal manure, high straw content, household waste, and green cuttings, grass from landscape maintenance or energy crops. Table 1 shows the characteristics of anaerobic digesters technologies while Table 2 shows the comparison of various digesters types.

Table 1: Main characteristics of Anaerobic Digester technologies

Table 2: Comparison of various Digester Types

Developing a biogas plant design is essentially the final stage of the planning process. However, it is mandatory for the designer to familiarize themselves with basic design considerations in advance. Ultimately, a successful plant design should be able to respond to quite a number of factors, and these include:

A. Climate

The design should respond to the prevailing climatic conditions of the location. Bearing in mind that biogas plants operate optimally at temperature ranges between 30°C to 40°C, in cooler regions, it is advisable for the designer to incorporate insulation and heating accessories to the design.

B. Substrate quality and quantity

The type and amount of substrate to be used on the plant will dictate the sizing of the digester as well as the inlet and outlet design.

C. Construction materials available

If the materials required for the plant set up can be sourced locally at affordable rates so as to maintain the plant set up costs within manageable ranges, then the design is preferred to that whose materials have to be imported.

D. Ground Conditions

Preliminary geotechnical investigations can guide the designer on the nature of the subsoil. In cases where the hardpan is a frequent occurrence, the design installation plan must be done in such a way that deep excavations are avoided because this would then increase the construction costs tremendously.

E. Skills and Labour

Biogas technology is sophisticated and hence requires high levels of specialized skilled labour. The labour factor cuts across from the planner to the constructor up to the user. However, gaps can be reduced through training of the involved parties at a cost.

F. Standardization

Prior to the commissioning of the design, the planner must carefully study the prevailing standards already on the market in terms of product quality and pricing, especially for large scale projects.

Several Decisions Support (DS) tools have been developed to give unbiased results when it comes to making decisions on technology selection. These include Multi-Criteria Decision Analysis (MCDA) techniques, the use of grey statistics and Technology Identification, Evaluation, and Selection (TIES) methods among others. In principle, all technology selection methods are based on the steps as summarised below;

MCDA is an approach employed by decision-makers to make recommendations from a set of finite seemingly similar options basing on how well they score against a predefined set of criteria. MCDA techniques aim to achieve a decisive goal from a set of alternatives using pre-set selection factors herein referred to as the criteria.

The selection criteria are assigned weights by the decision-maker basing on their level of importance. Then using appropriate techniques, the alternatives are awarded scores depending on how well they perform with regard to particular criteria. Finally, ranks of alternatives are computed as an aggregate sum of products of the alternatives with corresponding criteria. From the ranking, a decision is then made.

Multi-criteria decision analysis (MCDA) techniques can be successfully applied to choose a biogas digester technology from a list of potential alternatives for an anaerobic digestion (AD) system based on:

Using MCDA to analyse the various biodigester models presents a successful option owing to the fact that all the critical attributes are directly measurable and non-subjective.

A detailed feedstock analysis to determine the quantity and quality of the selected feedstock, which directly impacts the selected technology’s sizing needs to be completed. Using the MCDA technique, a suitable biogas model can be selected and from the substrate analysis, the appropriate size of the biogas digester can be determined.

The size of the digester, i.e. the digester volume Vd, is determined on the basis of the chosen retention time RT and the daily substrate input quantity Sd.

Vd = Sd x RT [m3 = m3/day x number of days] (2)

The retention time, in turn, is determined by the chosen/given digesting temperature. For an unheated biogas plant, the temperature prevailing in the digester can be assumed as 1-2 Kelvin above the soil temperature. The seasonal variation must be given due consideration, however, i.e. the digester must be sized for the least favourable season of the year. For a plant of simple design, the retention time should amount to at least 40 days. Practical experience shows that retention times of 60-80 days, or even 100 days or more, are no rarity when there is a shortage of substrate. On the other hand, extra-long retention times can increase the gas yield by as much as 40%.

The substrate input depends on how much water has to be added to the substrate in order to arrive at a desirable solids content (typically between 4 – 8% for wet digestion).

Substrate input (Sd) = biomass (B) + water (W) [m3/day] (3)

In most agricultural biogas plants, the mixing ratio for dung (cattle and / or pigs) and water (B:W) amounts to between 1:3 and 2:1. The ratio of B:W for the organic fraction of municipal solid waste (OFMSW) is in the region of 1:4.

The amount of biogas generated each day G [m3 gas/d], can only be estimated based on actual data recorded for the digester and substrate type and is calculated on the basis of the specific gas yield Gy of the substrate and the daily substrate input Sd.

The calculation can be based on:

The volatile solids content VS

G = VS × Gy(solids) [ m3/d = kg × m3/(d×kg) ] (4)

the weight of the moist mass B

G = B × Gy(moist mass) [ m3/d = kg × m3/(d×kg) ] (5)

The temperature dependency is given by:

Gy(T,RT) = mGy × f(T,RT) (6)

where

Gy(T,RT) = gas yield as a function of digester temperature and retention time

mGy = average specific gas yield, e.g. l/kg volatile solids content

f(T,RT) = multiplier for the gas yield as a function of digester temperature T and retention time RT

As a rule, it is advisable to calculate according to several different methods, since the available basic data are usually very imprecise, so that a higher degree of sizing certainty can be achieved by comparing and averaging the results.

The digester loading Ld is calculated from the daily total solids input TS/d or the daily volatile solids input VS/d and the digester volume Vd:

Ldt = TS/d ÷ Vd [kg / (m3 day)] (7)

and:

Ldv = VS/d ÷ Vd [kg / (m3 day)] (8)

Then, the calculated parameters should be checked against data from comparable plants in the region or from pertinent literature.

The size of the gasholder, i.e. the gasholder volume Vg, depends on the relative rates of gas generation and gas consumption. The gasholder must be designed to:

Vg1 = gcmax × tcmax = vcmax Vg2 = Gh × tzmax (9)

with

gcmax = maximum hourly gas consumption [m3/h]

tcmax = time of maximum consumption [h]

vcmax = maximum gas consumption [m3]

Gh = hourly gas production [m3/h] = G ÷ 24 h/d

tzmax = maximum zero-consumption time [h]

The larger Vg -value (Vg1 or Vg2) determines the size of the gasholder. A safety margin of 10-20% should be added:

Vg = 1.15 (±0.5) × max(Vg1,Vg2) (10)

Practical experience shows that 40-60% of the daily gas production normally has to be stored.

The ratio Vd ÷ Vg (digester volume ÷ gasholder volume) is a major factor with regard to the basic design of the biogas plant and ranges typically from 3:1 to 10:1 depending on the feedstock.

South Africa has experienced very limited market penetration for bio-digesters and biogas. In Germany, one of the leading European countries utilizing biogas, around 1000 plants are built every year. In India, more than 12 million plants, ranging from small domestic units to large commercial plants, are in operation. Even Uganda has more than double the estimated 300 biogas plants that South Africa are operating at present.

In South Africa the waste management landscape is changing rapidly since land around the larger metropoles for landfill use is becoming very limited and expensive. A rapid departure is needed from our current approach of only throwing away instead of recycling materials where possible and utilize the organic fraction of municipal solid waste (OFMSW) for biogas generation. South Africa has also ratified the Kyoto protocol and committed to reducing greenhouse gas (GHG) emissions by at least 34% by 2020, and a further 45% by 2030. The proposed Carbon Tax due for roll-out will also grease the wheels to promote more green technologies like biogas generation.

The market for gas in South Africa has been increasing steadily since the introduction of the natural gas from Mozambique to industries and in certain areas of Johannesburg even to residential customers. With the new technologies available to feasibly “clean up” the biogas by removing the trace elements of hydrogen sulphide and reduce the carbon dioxide it is possible to successfully store and pressurize the bio-methane. This enables not only the use of the biogas for electricity generation as in the past but also for utilization anywhere from heating, cooking and transportation fuels in the form of CNG or even LNG (Liquified Natural Gas).

EPCM Consultants has already monetized the only “natural” bio-gas reserves in South Africa by converting it to compressed natural gas (CNG) to run Harmony mining’s busses. EPCM is also currently developing the next step to liquefy the gas to increase the energy density and enable more opportunities for usage. More recently EPCM completed a design to convert a customer’s anaerobic digester to utilize the biogas generated from organic waste material as compressed natural gas (CNG), instead of generating electricity. They will be using the CNG to supplement their transportation fuel requirements increasing the value generation from their anaerobic digester.

Biogas as an almost previously untapped resource in South Africa presents huge opportunities for utilizing untapped renewable resources (from manure to organic wastes) to expand the gas market in areas not having access to the Sasol gas pipeline infrastructure by providing a cost-competitive clean energy source.

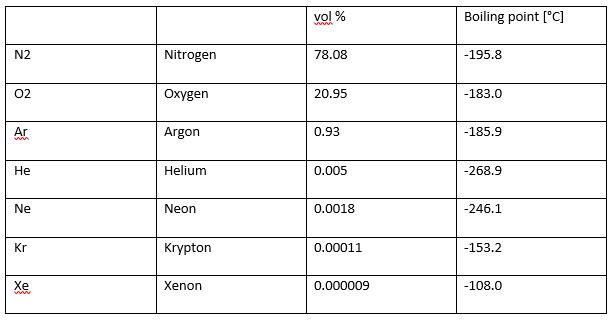

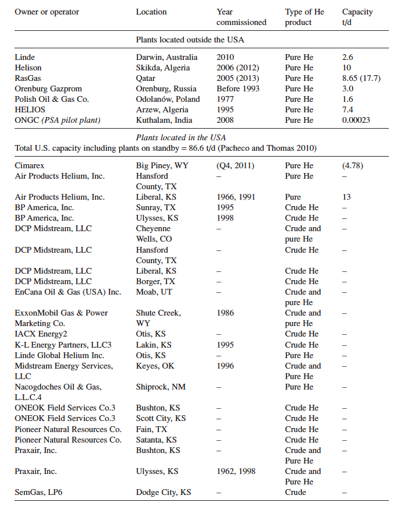

An Air Separation Unit (ASU) is a type of technology that separates air into its primary components. The most abundant are Nitrogen, followed by oxygen, and then argon, along with other inert gases in small amounts. The composition breakdown is summarised in Table 1 below.

Various methods or technologies can be used to separate air into its components. The oldest and most popular is cryogenic or fractional distillation. Other methods include pressure swing adsorption (PSA) and membrane technology, but hybrids of these technologies also exist, and new and improved methods are being researched. These three methods are explained in the sections that follow.

Table 1: Composition of Dry Air (Adapted from Linde Engineering, 2017)

Oxygen, constituting 21% of air by volume, is the most widely used air product with many industrial applications. The oxygen production from air separation is a large and growing industry, producing nearly 100 million tons of oxygen annually (Hashim, 2011), and demand is growing as future clean energy technologies increasingly rely on oxygen. While oxygen is the primary product, air separation methods also yield other air products with various by-products. These technologies vary in scale and application efficiency, as summarised in Table 2.

Table 2: Comparison of process alternatives for oxygen production from air separation (Adapted from Hashim, 2011).

For air to be separated into its different components, it must first be liquefied (liquefaction of air). Liquefaction occurs when a gas is subjected to temperatures and pressures below its critical point or conditions. The critical temperature of the air is -140.7°C (132.5 K), and the critical pressure is 37.7 bar. This means that air has to be cooled below this temperature to become a liquid for separation. This critical temperature varies depending on the pressure of the gas, in that a higher temperature is required for lower pressure. This relationship is proportional but not linear (Linde Engineering, 2017).

In 1895, Carl von Linde successfully liquefied air, attempting to obtain liquid carbon dioxide to be used in the brewing industry (Flavell-While, 2010). It was only later that separation methods were developed. This liquefaction process took three days. Separation methods have come a long way since then. Below is an early diagram of the liquefaction process.

Figure 1: Von Linde’s original drawing of his air liquefaction process (Flavell-While, 2010)

Cryogenic air separation is the most common and standard technology used for the separation of air into its constituents. It produces a high-purity product and is the most developed method to date (Hashim, 2011). This is a highly energy-intensive process due to the low temperatures that need to be achieved, as shown in Table 1 above.

The air is first filtered, compressed and then chilled to -185°C. This liquefies the air, and this liquid stream is sent to a distillation column to be separated. This uses the natural temperature gradient within the column to allow nitrogen to leave the top of the column as gas and oxygen as a liquid at the bottom. Argon can also be separated by taking a stream somewhere in the middle of the column where the argon concentration is the highest and feeding this into another column where nearly pure argon is separated from the other gases.

Some improvements to this process included using packed towers instead of traditional trayed towers, introducing heat integration, and using more efficient compressors to reduce energy consumption. Argon separation has also been improved. Conventionally, hydrogen catalytic converters were needed, but modern processes only require structured packings. This method is reaching its maturity level, and industries are looking at other air separation methods, which are continually being developed, as there is potential for high purity and lower energy consumption (Hashim, 2011).

Below are more detailed steps for a typical cryogenic air separation process (Linde Engineering, 2017). This process produces gaseous pure oxygen and nitrogen, as well as liquid oxygen, liquid nitrogen and liquid argon, with internal compression. A diagram for this process can be seen in Figure 2.

Figure 2: Typical Cryogenic Air Separation Process (Linde Engineering, © 2017)

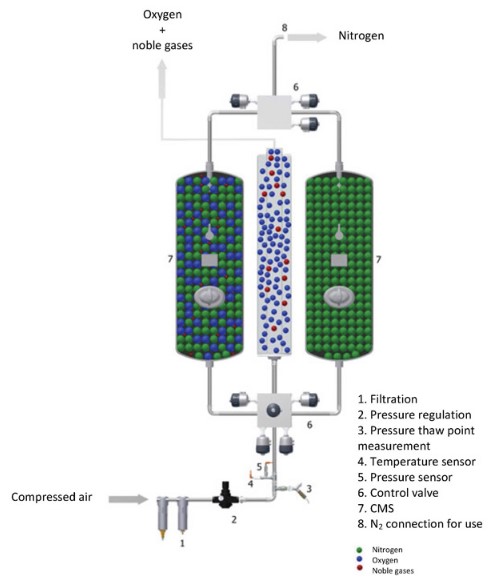

The basis of pressure swing adsorption (PSA) is that when gases are put under high pressure, they are attracted to solid surfaces and hence adsorbed. This is a proportional relationship in that the higher the pressure, the more gas is adsorbed. The adsorbent bed is known as a zeolite.

Filtered air enters the PSA generator, which contains zeolites that absorb nitrogen and/or argon. This is done at high pressures, which cause the gases to be attracted to the solid surface of the zeolites. Purified oxygen can then be separated. Once the oxygen has been collected, the pressure then swings to low pressure to desorb the nitrogen, which can also be collected. As soon as the pressure is reduced again, the gas is desorbed (released). This additionally frees up the adsorbent and makes it ready for the next cycle.

Different gases can be adsorbed by using different solid particles based on what the gases are more easily attracted to, so this method typically has relatively high product purity. However, by-product purity is still being improved. If the zeolite attracts nitrogen, then some or all of the nitrogen will be adsorbed when a stream of air is pressurised and can be released after it is depressurised again. The exiting stream will, therefore, be richer in oxygen compared to the entering stream, and this oxygen will be collected. The zeolite can then be reused for another batch. When two adsorbent vessels are used, the process becomes nearly continuous (Ruthven, 1990), as illustrated in Figure 3 below.

This is the most suitable method for producing oxygen for small to medium-scale plants (20-100 tons/day). Large-scale plants typically use cryogenic separation (more than 100-300 tons/day). This is also an older technology; hence, it has been perfected over the years in terms of adsorbents used and energy consumption. This is the favoured alternative to traditional cryogenic distillation, as it has a significantly lower energy demand and a high product purity. There are various variations of PSA, including vacuum swing adsorption, temperature swing adsorption, vacuum-pressure swing adsorption, and many more. These systems rely on the zeolites to trap nitrogen, producing oxygen with a purity of 90% to 95%. Different adsorbents are being investigated continuously to improve this process even more. The performance of this process is highly dependent on the pressure, which can be more energy-intensive, as greater energy is required for greater pressure and hence greater performance (Hashim, 2011).

The original pressure swing air separation process uses a zeolite adsorbent that is selective to nitrogen and hence produces an oxygen-rich exit stream. This method is predominately in small-scale units, but many modifications have been made to adapt this method for large-scale units to reduce energy demand. Nitrogen can theoretically be recovered from the desorption of the zeolite, but this is not of very high purity, so it is more desirable to use a zeolite that is selective to oxygen. This, however, is still being perfected (Ruthven, 1990).

Figure 3: Pressure Swing Adsorption Technology (Inmatec, 2017)

Figure 4: Schematic Representation of the Oxygen Transport in Dense MIEC Ceramic Membrane (Hashim, 2011)

The third type of air separation is via membrane separation technologies. This modern technology is not yet well established but is potentially very promising. This is the most recent technology, and new developments are constantly emerging from it, such as new types of membranes and hybrid systems involving both cryogenic distillation and pressure swing systems. Currently, dense ceramic membranes are used. This technique can separate oxygen from the air, usually at high temperatures of 800-900°C. This method also has high by-product purity recovery, so it can be used to potentially separate any component of air (Hashim, 2011).

Traditionally, ceramic membranes with mixed ionic electronic conducting (MIEC) characteristics have been explored due to their potential to produce high-purity oxygen. This type of membrane does not require electrodes or an external circuit to operate. As illustrated in Figure 4 above, the oxygen partial pressure gradient creates an internal short circuit through electronic conductivity (Hashim, 2011).

This method separates oxygen from air by taking advantage of the oxygen partial pressure gradient. There is a high oxygen partial pressure side of the membrane on the feed side and a low one on the sweep side. The oxygen naturally permeates from the high-pressure side to the low-pressure side. The flux of electrons through the membrane keeps the overall charge neutral. As the gas stream flows along the membrane, it is depleted of oxygen through the permeation of the membrane via the pressure gradient, and the sweep stream becomes oxygen-enriched. This sweep stream flows counter currently to the air feed. This oxygen is then collected (Hashim, 2011).

This technology is still in its early stages and continues to be researched. It holds the potential to produce a very high-quality product, with separation possible at high temperatures without the need for liquefaction. Although not yet widely used, it is predicted to become the dominant method in the industry in the future (Hashim, 2011).

References:

Bibliography:

The future of natural gas and liquid natural gas (LNG) looks promising in Africa as a natural gas resource and a potential import market. African governments are eyeing clean energy as a bridge to rapid economic growth. However, the key stumbling block has been its transportation options. Nevertheless, natural gas liquefaction now opens the possibility of better transportation logistics. This article is a summarized report of the research documented by the Department of Energy in the Office of International Affairs in the U.S. It aims to explore the feasibility and understanding of Natural Gas and LNG projects in Africa.

EPCM has categorized this summary into five main sections:

Natural gas marketing can be viewed from two perspectives: the local market and the global market.

The first overseas gas trade occurred in 1959 between the United States and the United Kingdom. Since then, regions have been teaming up depending on their proximity to reduce LNG transportation costs. Today, the global gas market comprises three primary regions: Europe, the Asia-Pacific (currently the largest market), and North America (Atlantic Basin). Japan, South Korea, and Taiwan are the world’s leading importers of LNG, with India and China slowly catching up.

While there is more than enough demand for natural gas, oversupply has been a threat in the past. However, as more uses of natural gas are discovered each day, a shortage in its supply is also possible. In 2016, 258 million metric tonnes of LNG were traded globally. Nineteen countries exported LNG, while 34 countries imported it.

The above factors have led to an oversupply of LNG in the global market, resulting in a significant price drop. This situation could persist as a short- to medium-term crisis. Before planning new projects, new gas investors should carefully forecast when market rebalancing may occur. The key is to have sales above the marginal cost of production. Commercial and financial pressures may drive a short-term realignment of the LNG market; however, if this correction does not occur, oversupply could extend well into the next decade.

The domestic market has a solid demand for compressed natural gas (CNG) and its by-products, such as petroleum liquids. Transportation is also cost-effective where pipeline transmission can be used. The host’s national gas company markets the gas locally and develops the necessary infrastructure.

In Africa, domestic and regional pipelines have expanded the local market, and manufacturing industries continue to drive demand for CNG as a feedstock. Additionally, CNG is a favoured fuel source for power generation and gas-powered vehicles. However, infrastructure and market development remain limited.

Domestic markets have more demand for natural gas as a fuel for power production. For investors, proper planning is critical to ascertain reliability. Cost-effectiveness and safety of the end product (both to the users and the environment) should also be considered. Identify demand centres (bearing in mind future expansions). Then, decide whether to build these power plants closer to the gas source or the demand centres. A few factors to consider include;

Here is a link for more information on how natural gas fuels power generation.

A potential natural gas customer (vehicle, power plant, or ship) has to be convinced that this gas will always be available. The gas must also outweigh their current options and the risk associated with change.

Sub-Saharan African countries have the potential to become major natural gas producers. Gas reserves are being explored daily. Tanzania and Mozambique recently discovered gas reserves of over 250 trillion cubic feet (TCF).

Most African nations also have a potential LNG import market due to:

According to the September 2016 report generated by the U.S. Power Africa Roadmap, one of the Vision 2030 goals in sub-Saharan Africa is to increase power generation by over 30,000 megawatts (MW). Assuming natural gas is their preferred energy source, this translates to over 42 MTPA of liquid natural gas. In addition, the African Development Bank Group, via the Energy for Africa project, aims to make electricity available to all nations by 2025.

In Africa, natural gas prices vary. They are established by the seller after some negotiation with the buyers. The prices range between $1.21/MMBtu and $8.4/MMBtu (a case study in Mozambique, Ghana, and Nigeria). The market demand is so good that most African gas producers focus on the domestic market. Nigeria is a good example.

Pipelines face significant challenges in offering flexibility, especially in mountainous regions or areas with insecure borders, where piped gas supply may not be feasible. In such cases, compressed natural gas becomes their plan B. However, pipeline supplies still pose a threat to LNG markets. Primary causes of market uncertainties include:

These factors often lead shippers to sell cargoes initially reserved for long-term gas contracts. This approach assists in offsetting the initial costs of infrastructure and LNG carriers. However, these conditions negatively impact the efficient transportation and marketing of LNG.

A typical natural gas project is capital-intensive and can last between 20 and 40 years. Investors must allocate risk and define the functions of each participant. This will ascertain sufficient returns on investment and the ability to pay off debts. Consider the possibility of future expansion as well. Poorly structured projects scare off potential buyers due to the high risk involved.

The most expensive area in an export structure is the liquefaction project. To cut down these costs, investors have a choice of four major commercial structures:

Here, the natural gas producer owns LNG export facilities, the liquefaction units, and the upstream section (exploration and production). He is also responsible for all LNG agreements (both purchase and sale). Revenues come from direct LNG sales. Examples include Qatargas, Sakhalin Island, Tanggu, and Snohvit projects.

This structure separates the owner (producer, buyer, or aggregator) of natural gas from the owner of the export facilities. As a result, the overall project cost is significantly reduced because an independent company provides liquefaction services. However, the gas owner bears all the risks (cost, supply, and demand). Revenues come from tariff payments made by the terminal’s customers. Examples include Damietta, train 4, Freeport LNG and Cove Point facilities.

The liquid natural gas export facility’s owner differs from that of the natural gas producer. The liquefaction project company enters a purchase agreement with the producer. And this is how revenue is generated. This structure allows for more than one natural gas supplier (or producer). Examples include Equatorial Guinea, Angola, Malaysia, and Nigeria.

Here, the investors make their commercial structure by combining some principles from the above three structures. It is common for the host government or independent contractors to demand full participation. They drill the gas, market it, and retain full ownership while the other party benefits from charging a fixed monthly reservation. Examples include Corpus Christi and Cheniere’s Sabine Pass projects.

The commercial structure chosen will impact the project’s overall success. Structures that don’t favour local investors tend to have limited expansion. Remember that the government has the final say on licenses and project approvals. Therefore, factoring them in when choosing a project structure and making critical project decisions is imperative.

Import facilities cost relatively less when compared to the export structures. However, they share the same operating principles (integrated, tolling, and merchant structures). The only difference is that in the absence of an export facility, we constructed a regas terminal. In a nutshell:

Integrated structures – gas owners (who are also the producers) add a regas terminal. Consequently, they can sell this gas to local and distant markets.

Tolling structures – The import terminal charges a fee for everything (regasification, offloading, and storage).

Merchant structures – Import project owner buys LNG, regasifies, and sells to consumers.

The government can participate directly or directly in the national oil company. Its support is vital for investors to get proper approvals. Investors also need support to gain access to the country’s natural gas resources. Other roles include:

Most projects practice a staged project finance structure, while donors finance others directly. LNG projects have more than one financer. Three principal factors influence LNG projects’ financing:

Investors need to be careful with the liabilities of a partnership when sourcing for funding. A “Limited recourse” finance plan takes care of such liabilities. For higher-risk countries, Public-Private Partnerships are the best approach. Other financing considerations include:

The time it takes for an investor’s loan to be approved depends on several factors, but the most important are the size of the project and the amount of risk involved. However, the current unstable gas market is posing a threat to project funding. The potential sources of financing for LNG projects include bank debts, ECAs (Export credit agencies), sponsors, multilateral, equity, and bonds.

LNG prices vary from segment to segment, and setting the right prices is crucial for an investor. Several formulas already exist for setting LNG prices, but most follow oil-based pricing. Europe, however, has recently adopted pricing based on the gas-on-gas method.

In Africa, the goal is to move to LNG imports and establish small-scale LNG projects. As a result, no pricing mechanism has been set yet.

Most African nations are adopting floating liquefaction solutions instead of the usual expensive trains. This is because of the resources’ remote location and environmental issues. Instead of trains, the liquefaction process occurs at sea on the vessel: the same process but with different technology.

In the past, most LNG carriers had an average capacity of 125,000 cubic meters. Today, however, LNG carriers (particularly Qatari ships) have a capacity of up to 266,000 cubic meters, with the largest accommodating 6 billion cubic feet of gas. Modern ships not only provide a more substantial carrying capacity, but they are also more fuel-efficient and have reduced operating costs. The cost of these vessels is equally high. Most cost over $200 million, with a daily charter rate of over $80,000. Ships without secure long-term charters often face economic challenges due to the less lucrative short-term charters available.

In addition, LNG sellers pass on their cost pressures (resulting from gas oversupply) to shippers. This has led to a shift in charter agreements, where shippers are compensated for the loaded leg of the journey but only receive a modest bonus for the return leg. To combat the current downturn in the shipping market, many shippers are converting their LNG carriers into multipurpose floating facilities, with floating liquefaction (FLNG) facilities being the most common. These converted carriers are ideal for African markets to initiate a reliable gas stream for use in power projects. Later, indigenously produced gas can supplement LNG imports. This is after the projects have been undertaken and the domestic market has grown.

Currently, shippers are using smaller marine carriers, known as the “break-bulk” approach. They use even smaller vessels to reload regasified LNG from their regasification terminals. Storage considerations are essential to ensure adequate gas supply during peak demand periods. Finally, for small-scale LNG projects, trucks and small ships are the preferred modes of transportation.

Natural gas production can be categorized into three major stages:

In developing countries, national oil companies dominate the exploration phase with some help from international oil companies. This is due to their lack of experience and the high capital required. Smaller international companies also get involved but fail to complete the projects. Strategic planning determines the overall success of this stage. If this stage succeeds, the rest are more likely to succeed.

The feed gas is sent to a processing plant for further refining. Liquefaction then occurs, which makes LNG more space-efficient for enhanced transportation. However, processing and liquefaction are the most expensive part of the value chain. As such, this stage will benefit more from careful project management and support from local authorities. Proper shipping and domestic market supply arrangements will also hasten capital and cost recovery. They also enhance revenue generation. That will make the investor look “good” to the host country’s citizens.

Specialized LNG carriers transport the liquefied product to a regasification facility. Asians have dominated the shipbuilding industry due to their in-depth design experience. Investors (gas buyers or sellers) then charter these ships for some time (usually the entire project period). However, major project consortiums (like the Qatar projects) build their own ships. The success of this stage depends on the availability of these carriers when needed – usually when the terminal commences operations. The infrastructure, other trucking, and local maritime shipping should also be ready.

An increase in temperature returns LNG to its gaseous form during this stage. The major requirements include a docking facility (for LNG carriers), additional cryogenic tanks (to hold the gas awaiting regasification), and the regasification plant. For this stage to succeed, it will require sufficient regasification capacity.

This is where the host country’s citizens benefit the most. This is due to the establishment of gas infrastructure to facilitate domestic supply. Overall, buyers’ and sellers’ price negotiations and the ability to adapt to any future gas market changes contribute to the success of this stage.

Note

For a successful project, the national government and the contracted international oil companies must coordinate the operations of the entire value chain. Since natural gas is not a commodity business, each party needs to see value addition for the entire project period. For example, the host country will be happy to see cheap local gas supply over the project period, while the drilling oil company will appreciate developed domestic supply infrastructure and enhanced security. It’s a win-win situation.

Short-term contracts are becoming popular due to challenges in long-term project forecasts. LNG projects are generally capital-intensive. The currently projected market oversupply combined with low prices makes it impossible for the entire value chain to appear profitable. However, a dedicated shipping plan might ease the load for long-term projects.

Operational, strategic, and market risks should be shared among the stakeholders (the project developer, host government, upstream developer, EPC contractor, financiers, and LNG buyer). Other risks include:

In African countries, price risk plays the biggest role in LNG investment decisions. The Equator Principles (a risk management framework) used by financing institutions can be applied by gas investors.

Africa is booming with unexplored potential in natural gas and LNG. As the local governments continue to equip their citizens with the relevant skills, investors can now confidently access these resources. It is important to mention that unemployment is a major crisis in most African nations. Therefore, investors must manage high expectations that could lead to social conflicts. Nevertheless, proper planning and forecasting are the most crucial steps for the success of any LNG project. Here is a link to the original report for further reading.

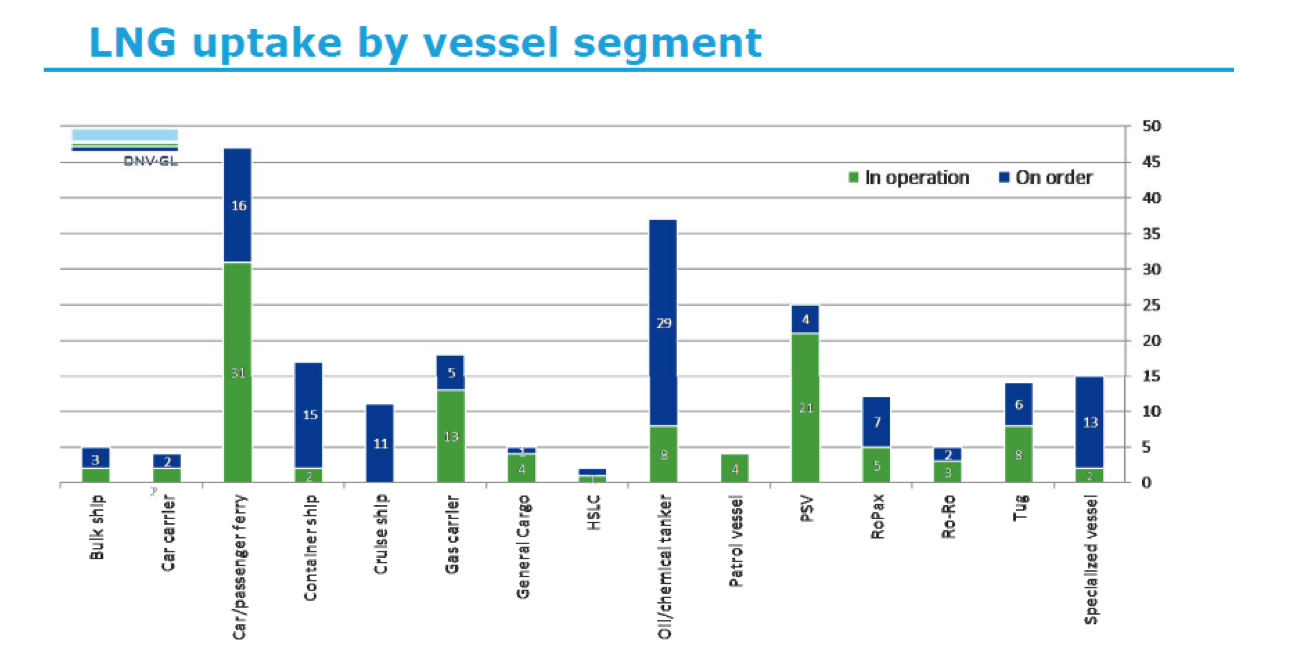

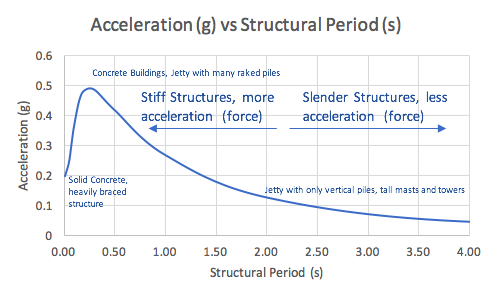

Global maritime transport has traditionally relied on marine and heavy fuel oils (HFO) for propulsion. Whilst these fuels are cost-effective and bunkering is widely available worldwide, they produce harmful emissions. In response, stricter regulations and laws are being implemented to limit ship emissions, leading to the growing adoption of liquefied natural gas (LNG) as a cleaner alternative for marine bunkering fuel.

In light of new regulations aimed at reducing the environmental impact of shipping, fleet owners are looking for alternative solutions. LNG has emerged as a viable, cost-effective alternative, offering significant emissions reductions compared to traditional fuels.

This form of propulsion has been used on LNG carriers for decades (using the boil-off gas from LNG onboard tanks), with about 400-500 in operation today (2017). However, it was only in 2000 that a non-LNG carrier first used LNG as bunkering fuel.

Since then, this market has grown rapidly, with over 100 LNG-fuelled vessels (that are non-LNG carriers) in operation and an equal number on order (2017).

The International Maritime Organisation (IMO) developed the MARPOL Convention (International Convention for the Prevention of Pollution from Ships) to protect the marine environment. The latest annexe, which came into force in May 2005, aims to regulate air pollution emitted by ships, including Nitrogen oxides (NOx), Sulphur Oxides (SOx) and other volatile organic compounds. It also requires the establishment of Emission Control Areas (ECAs), areas in which stricter controls are in place to minimise airborne emissions.

The established ECAs are:

1. Baltic Sea area

2. North Sea area

3. North American area

4. The United States Caribbean Sea area (around Puerto Rico and the United States Virgin Islands)

In October 2016, the IMO established that a global 0.5% (mass by mass) sulphur limit will apply to fuel oil used by ships from 1 January 2020. Within the ECAs, a sulphur limit of 0.10% m/m has been applied since 1 January 2015.

The limits for SOx are:

| Outside an ECA | Inside an ECA | ||

| Prior to 1 January 2012: | 4.50% m/m | Prior to 1 July 2010: | 1.50 % m/m |

| From 1 January 2012: | 3.50% m/m | From 1 July 2010: | 1.00 % m/m |

| From 1 January 2020: | 0.50% m/m | From 1 January 2015: | 0.10 % m/m |

This implies that vessels must either use a compliant fuel or switch from any high sulphur-content fuel to a compliant marine fuel before entering an ECA.

Strict enforcement and inspections will be implemented, especially in European ports. Fines are expected to be levied to offset the economic advantages that may result from disregarding these limits.

Current and Future Sulphur Regulations

LNG primarily consists of methane (CH4), which reduces carbon dioxide (CO2) emissions by up to 30% when used as a fuel. Less nitrogen is present in the combustion process due to the compression rations and methane combustion temperatures, reducing the production of nitrogen oxides (NOx) by up to 85%. Additionally, LNG contains no sulfur, leading to a 100% reduction in sulfur oxide (SOx) emissions. In its liquid form, LNG is non-corrosive, non-toxic, and non-flammable. It is also comparable in cost to traditional marine fuels. However, this depends on the availability of LNG bunkering infrastructure for the vessel, and it also offers the advantage of reduced operating costs.

Increasing stringent regulations will require additional investments to reduce SOx and NOx emissions. Although LNG has a high investment cost, the associated operational savings can be substantial, depending on fuel prices. Alternatives, such as exhaust gas treatment systems, significantly increase the overall cost of the vessel. These systems also require additional space and can increase fuel consumption by 2-3%. Therefore, the use of LNG, which is sulfur-free, presents a viable solution for meeting emission limits.

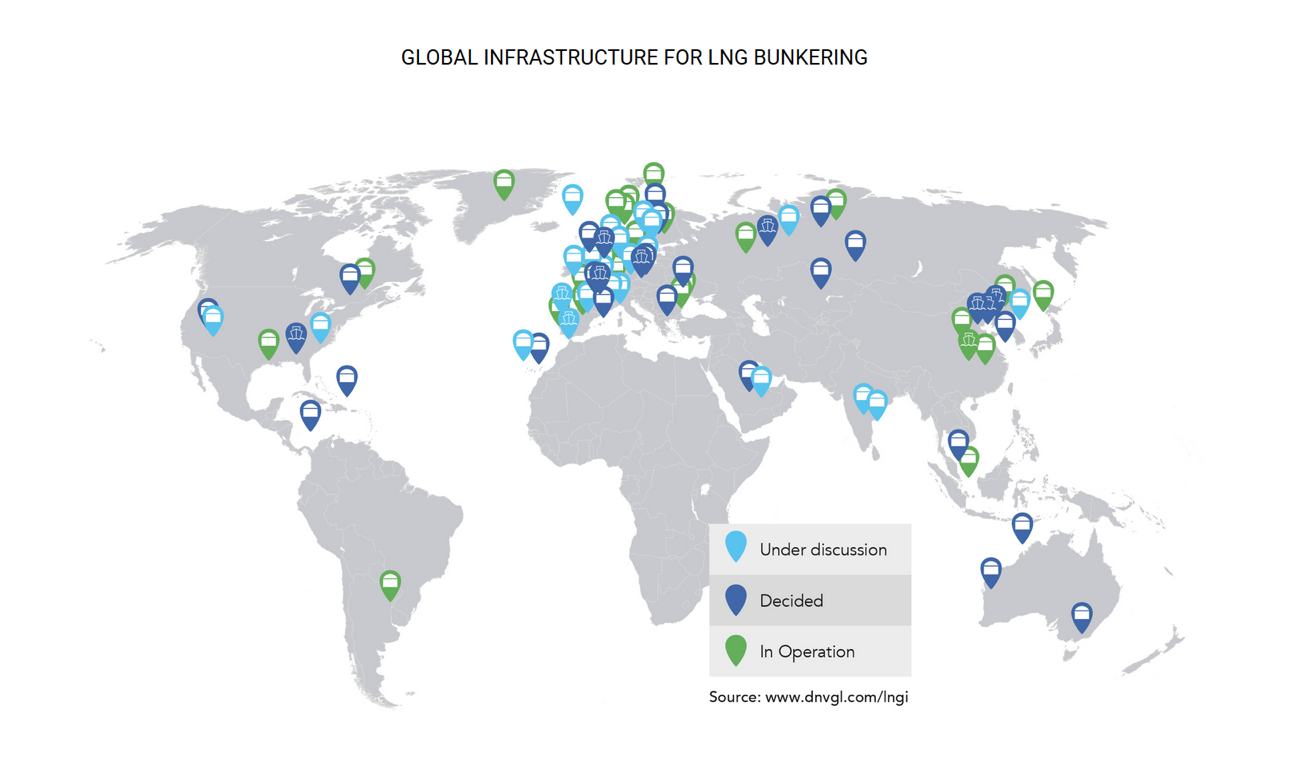

LNG is widely available, with 20 countries exporting the fuel and 35 importing it. However, existing port infrastructure is focused on these import and export activities, which do not cater to small-scale vessel refuelling. Facilities that provide for the refuelling of ships at ports are termed bunkering and are increasingly being provided worldwide. LNG bunkering infrastructure is currently concentrated heavily in Europe.

LNG is imported in large LNG tankers, with common storage capacities ranging between 80,000 and 260,000 cubic metres. These vessels are substantial in size and cannot be used to deliver LNG to smaller terminals. Instead, smaller LNG feeder vessels, typically ranging from 7,500 to 20,000 cubic meters, supply these smaller terminals in ports. Integrating transfer facilities with existing port infrastructure can be challenging; consequently, bunker vessels are often employed to transfer LNG to ships.

Bunkering requires storage and transfer facilities. LNG can be transferred to vessels from a stationary shore-based tank by pipeline or from mobile units in the form of vessels (ship-to-ship transfer) and trucks (truck-to-ship). The mobile units require their own LNG supply source in the form of strategically placed terminals. The ship-to-ship transfer is the transfer of LNG from a vessel or barge, with LNG as cargo, to another vessel to use as fuel. It can be done at sea or at a port, allowing large volumes to be transferred. The development costs can, however, be high and require space to accommodate the vessels in a port. The truck-to-ship transfer is flexible and costs less, but the quantity of fuel that can be transferred is smaller, and the loading is lower. The ship-to-shore transfer is desirable for large volumes and has a faster turnaround time. However, it requires a large investment to build the facilities in ports. LNG can also be supplied in standardised containers and loaded directly onto the ship.

LNG bunkering is currently available at over 60 locations, with an additional 70 facilities in the planning stages. By the end of 2017, six LNG bunker vessels are expected to be in operation, enabling ship-to-ship bunkering in Northwest Europe and the USA.

The design of LNG storage tanks has to adhere to the various codes. The type, size and tank locations are important considerations. LNG requires approximately four times the storage space required for conventional fuels, so an optimum layout is important. The location of tanks is important from a safety perspective, with their position being restricted by IMO guidelines. The tanks have to be well insulated, and a surrounding safe area is required in case of accidental spillage.

The boil-off gas increases the pressure in the storage tanks. The tanks are, therefore, designed to handle higher pressures and are fitted with pressure relief valves to allow the venting of gas to the atmosphere if the pressures become excessive. Venting gas is only allowed in emergencies and is not a method for pressure control. Venting of the gas is also undesirable from an economic and environmental perspective. The more volatile components of LNG (nitrogen and methane) boil off first, changing the composition and quality of LNG over time. This is known as ageing.

Some methods to manage the boil-off gas are:

The first LNG-fueled vessels that were not LNG carriers used gas-only engines. Dual-fuel (DF) engines can operate on either gas or diesel fuel and can also run on a combination of both, with approximately 70% of energy derived from gas and 30% from diesel. This option is suited to refits of engines that cannot be converted to dual fuel. The most prominent engine manufacturers are currently Wärtsilä, MAN, Caterpillar, HiMSEN, Siemens, Mitsubishi and Rolls Royce.

LNG-ready vessels allow the vessels to be converted to LNG-fuelled vessels in the future. Measures can include structural reinforcements and the correct choice of material to support future LNG tanks, preparations for future gas fuel systems and installation of machinery which can be converted to gas fuel (or is already capable of burning gas fuel). This simplifies a later conversion. An LNG-ready ship is suitable where the current market conditions and/or LNG availability do not make current commercial sense. The additional investment can then be made when the commercial situation is favourable. Being LNG-ready, therefore, increases the flexibility of the vessel, extends its lifetime and can increase its second-hand value.

Converting existing diesel engines for LNG operation is relatively straightforward. This process typically involves changes to the cylinder heads and liners, pistons and rings, connecting rods and turbochargers. Gas rails and admission valves, together with a pilot fuel system and the fitment of storage tanks, were also required.

IMO regulations require a fully redundant fuel supply system. Where gas-only is used, the LNG has to be stored in two or more tanks of approximately equal size. Dual fuel engines are allowed to have a single LNG storage tank, with liquid fuel as a backup.

LNG brings some unique safety considerations when compared with heavy fuel oils. LNG is non-flammable due to a lack of oxygen in the liquid. However, when LNG vapourises, the resulting natural gas becomes flammable when mixed with air in concentrations ranging from 5% to 15% (by volume). Natural gas is both odourless and colourless, and LNG cannot be odorized, making detection without specialized equipment difficult.

LNG’s low temperature (-162 degrees Celsius) can result in severe injuries from direct body contact. It can also render normal ship steel very brittle and fracture it when exposed to LNG.

Due to the large energy content contained in the LNG storage tank, it must be protected. This entails protecting it from possible ship collision and grounding, mechanical impacts, external fires, and BLEVE (boiling liquid expanding vapour explosion).

Despite the associated risks, LNG has proven to be a safe fuel choice for marine transport. The guidelines set by the IMO and the IGF Code ensure that the design and operation of ships adhere to best practices, thereby minimizing potential risks.

The first LNG-fuelled vessel that was not an LNG carrier was the Norwegian ferry Glutra, which came into service in 2000. Within three years, two oil and gas platform supply vessels (PSV) also began operation in Norway. Since then, there has been an increasing rate of new LNG-fueled vessels coming into service. Norway’s tax on NOx, introduced in 2007, and the availability of LNG in the region helped spur the introduction of LNG-fuelled vessels there. Until 2013, all 37 LNG-fuelled vessels (bar one) were based in Norway. The formation of ECA’s in Europe and North America and a steep increase in the price of heavy fuel oils led to more consideration for LNG as a marine fuel. As of May 2017, there are 106 vessels in operation, with an additional 115 on order.

There has also been a diversification in the type of LNG-fuelled vessels, and the areas of operation are expanding.

The gas market has experienced a recent boom, driven partly by the surge in non-traditional (shale) gas production, which utilizes the hydraulic fracturing (fracking) process.

The European Union is actively promoting the use of LNG and funding projects to improve its supply. Current EU policy requires at least one LNG bunkering port in each member state.

The Society for Gas as a Marine Fuel (SGMF) was established in 2014 following a decision by the Society of International Gas Tankers and Terminal Operators (SIGTTO). SGMF is an NGO that aims to promote the safe and responsible operation of LNG-fuelled vessels and develop guidelines for best practices amongst its members. Multi-sector industry organisations, such as SEA/LNG (founded in 2016), are also being formed to create coalitions to promote LNG as a marine fuel. SEA/LNG unites key stakeholders, including shipping companies, LNG suppliers, bunkering companies, ports, and engine manufacturers, to create coalitions that advocate for the use of LNG in marine transport.

EPCM LNG Archive

International Maritime Organisation

International Maritime Organisation – 2020 Global Sulphur Limit

IMO Studies On The Feasibility and Use of LNG as a Fuel for Shipping

IMO – MARPOL International Conventional for The Prevention of Pollution from Ships

SEA\LNG is a multi-sector industry coalition created to accelerate the widespread adoption of LNG as a marine fuel. Our vision is to establish a competitive global LNG value chain for cleaner maritime shipping by 2020.

Natural gas is formed when layers of decomposing plant and animal matter are exposed to intense heat and pressure under the Earth’s surface over millions of years.

This occurrence occurs not only on dry land but also underneath the seafloor. Being sealed off in an oxygen-free environment, the organic material undergoes a thermal breakdown process because the increasing heat and pressure convert the matter into hydrocarbons.

The lightest component of the newly formed hydrocarbon leaves the matter in a gaseous state known as Natural Gas. Once natural gas is completely formed, the odds of the gas being extracted depend on two characteristics of the surrounding rock: porosity and permeability.

Porosity refers to the amount of empty space within a rock’s grains. Sandstone is a typical example of high-porosity rock with large amounts of storage space for fluids such as oil, water and gas.

Permeability, on the other hand, is the measure to which the pore spaces in a rock are interconnected. The higher the permeability of the rock, the easier it will allow fluid to flow through it.

Figure 1. Illustration of Porosity vs. Permeability

This leads to natural gas flowing upwards through rocks with higher permeability due to its low density compared to surrounding rocks.

The natural gas deposits found today are due to upward gas flow through permeable rock until it reaches rock with such low permeability that it can’t flow any further and becomes trapped before reaching the atmosphere.

There are two main categories of natural gas based on origin and location: conventional and unconventional.

Conventional natural gas is often found together with oil reservoir deposits and can be extracted by drilling vertical wells and using traditional pumping techniques. Due to buoyancy, the natural gas will often be found floating on top of the oil or mixed with the oil (Student Energy, Conventional gas).

Unconventional natural gas deposits include shale gas, tight gas sandstone, coalbed methane and methane hydrates, to name a few. Unconventional natural gas is mainly formed deep within the earth, as illustrated in Figure 3. The natural gas deposits trapped deep within these rocks are hard to extract. However, recent technological advances in this field have made it possible to extract a large amount of natural gas from these sources economically. Gas reservoirs are considered unconventional when specialized extraction methods such as hydraulic fracking and horizontal drilling must be used to extract the gas.

Read more about these advances by following the links below:

Figure 2. Illustration of Different Layers of Natural Gas Deposits

Shale gas is trapped deep within the earth in gas-rich shale rock layers. It is extracted using a fracturing or hydraulic fracturing process. Shale gas wells are typically drilled to depths of 1500m – 4000m, with the average wells estimated at 2500m.

Only drilling a vertical well into the shale layer will not release enough gas to make the process economical. This is mainly due to the gas trapped in the low-permeable shale rock. This is why specialized drilling is the only way to extract large amounts of shale gas. Gas-rich shale rock layers make up a large area of the earth’s rock layers, which is exactly why shale gas is one of the largest natural gas resources in the world.

Methane gas deposits are commonly found in underground coal reservoirs, which is considered a natural occurrence. However, methane poses a threat to underground coal mining activities due to the large volumes released and its flammable nature. Therefore, it is feasible to tap into coal seams and extract the gas in a controlled manner, known as coalbed methane, which is a form of natural gas.

Coalbed methane is also referred to as sweet gas, coalbed gas and Coal Mine Methane (CMM). The gas can be extracted using various methods, such as UCG (Underground Coal Gasification), well drilling, and hydraulic fracturing, which are similar to the methods used to extract shale gas. Compared to shale gas deposits, the amount of gas extracted from coal beds is quite small. Coalbed methane has contributed to environmentally friendly extraction methods by injecting carbon dioxide into hard-to-access coal seams, which displaces the trapped methane. This process enhances the recovery of methane-rich natural gas while also storing carbon dioxide underground.

When natural gas flows into rock reservoirs with high porosity but low permeability, it can be referred to as tight gas. Typically, tight gas is held in rocks with pores up to 20,000 times smaller than a human hair, making it nearly impossible for the gas to flow freely.

Because of the nature of the rocks in which it is stored, tight gas commonly requires hydraulic fracturing and horizontal drilling to be released.

Methane hydrates are the most recently discovered and researched form of natural gas. They are formed by methane molecules trapped within a cage of water molecules. Methane hydrates occur naturally in a solid crystalline form, commonly found in sediments in Arctic regions and deep beneath the ocean floor. Although they may resemble ice crystals, methane hydrates will ignite when set alight.

Methane hydrates are estimated to be the planet’s most abundant source of unconventional natural gas (refer to Figure 5). However, there is still much uncertainty about the exact amount of methane hydrate sources. Due to the technical difficulties of extracting this energy source, methane hydrates are considered the most difficult natural gas resource to extract. Economically, extracting the gas remains challenging; only fractions of this resource are found in large enough concentrated volumes to make extraction feasible.

Figure 4. World Map Showing Estimated Methane Hydrate Locations

Certain types of bacteria can produce methane in large quantities through the breakdown of organic matter in an oxygen-free (anaerobic) environment.The bacteria are commonly known as methanogens. With methane being the main component in natural gas, the produced methane-rich gas is considered a type of natural gas referred to as biogenic gas or biogas. Biogenic gas must be differentiated from Thermogenic gas (fossil gas), which is produced from organic material deep in the earth and subjected to high pressures and temperatures. Biogenic gas typically forms closer to the earth’s surface than other unconventional natural gas sources. Thermogenic and biogenic gases have identical properties, but their compositions may differ in some cases.

Figure 5. Typical Composition of Biogenic Gas

Any organic matter is considered a potential source for producing biogenic/bio-gas. Food waste, livestock manure and sewage are just a few examples and can all be broken down into smaller categories. Biogas is considered a major renewable energy source. A popular method for producing biogas is using an Anaerobic Digester system. The gas produced by the digester can then be used to produce electricity from gas-powered generators. It is common practice for farmers around the world to produce biogas from an anaerobic digestion process by using livestock manure or vegetable/food waste as feedstock. Landfill sites can be considered as another major production source of biogas. Large amounts of municipal waste are buried in landfills, which will then start producing biogas, much like an anaerobic digester. The methanogens will start breaking down the organic matter in landfills, such as food waste and newspapers, producing gases such as methane and carbon dioxide. These gases can then be captured and separated before being implemented productively in the energy sector. When implementing biogas, a reduction in greenhouse gas emissions can be expected.

Before implementing any extraction method, the location of natural gas deposits must be established. This can be done using seismic testing, similar to the methods used for locating petroleum deposits. Gas prospectors use seismic trucks or more complex three-dimensional tools to set off a series of small charges close to the earth’s surface, generating seismic waves thousands of meters below the surface in potential underground rock formations such as shale rock and coalbeds. Geophysicists then interpret the results of the seismic waves by using acoustic receivers known as geophones. They then measure the travel times of the waves through the earth, after which a picture is constructed of the subsurface structure and potential natural gas deposits are identified. An exploratory well must be drilled to establish whether the identified gas deposits contain economically viable amounts of natural gas. Once the amount of natural gas is determined, the following extraction methods can be implemented.

Rwanda has implemented the first natural gas extraction method in the world. A natural gas extraction barge is located on Lake Kivu and is the largest extraction plant of its kind in the world. Gas bubbles are extracted from the water and processed accordingly. For further insight into this fascinating development, watch the video and explore the detailed article via the link below:

Hydraulic fracturing, widely referred to as fracking, was developed to extract gas from very low-permeability rock, such as shale rock. The process consists of injecting large volumes of water mixed with sand and various fluid chemicals at high pressure into a well to fracture the above-mentioned rock. This increases the rock’s permeability and the production rate at which the specific well produces gas.

The typical procedure for extracting shale gas through fracking follows these steps:

Once a gas-rich shale rock location is identified, a production well is drilled vertically until it reaches the shale formation. The wellbore then turns horizontally to follow the shale rock. Advances in horizontal drilling have made it possible for a single well to pass through larger volumes of shale, allowing more gas to be extracted.

A steel casing is inserted into the well to ensure it remains open and to protect the wellbore’s integrity. Cement is then pumped into the well and forced up the outside of the casing to seal the well, preventing fracking fluid, natural gas, chemicals, and produced water from leaking into surrounding groundwater supplies.

Once the well is sealed, small explosives are detonated in the horizontal section to create holes at specified intervals where fracking will occur. Fracturing fluid is pumped into the well at controlled pressures to fracture the rock several hundred meters from the well. Sand mixed with the fluid holds the cracks open when pumped out. After fracturing, gas flows freely to the surface, where it is collected in a controlled manner.

Underground coal gasification is an industry process that converts coal into gas while it is still underground. It involves drilling wells into the coalbed layer. Oxygen and water are then injected into the well. Once the well is injected with the appropriate amounts of oxygen and water, the coal is partially buried underground. The burned coal then produces a type of natural gas that starts flowing towards the surface. An animation of the USG process can be seen in the video below:

Vertical well drilling is a common method for extracting natural gas. After exploration, well locations are determined. Many natural gas reservoirs, particularly conventional ones, are found at relatively shallow depths. Horizontal drilling or hydraulic fracturing is not necessary to extract natural gas from these reservoirs because the gas pockets are typically found close to the earth’s surface and not in tight rock layers. These natural gas deposits are primarily of bacterial origin, continuously producing gas at relatively shallow depths, and are classified as biogenic gas. Vertical wells are drilled at depths varying from 300m-800m until a gas pocket is reached and gas starts flowing toward the surface. Horizontal drilling may be considered in some cases to interconnect wells and gas pockets in an underground system to increase the flow of wells. These natural gas wells usually produce gas at low pressures varying from 0.2 to 4 bar.

Continuous Carbon Capture Process: In recent years, greenhouse gases have been identified as the major culprits of climate change, and carbon dioxide constitutes as much as 70% of the greenhouse gases emitted (U.S. Department of Energy, 2007). As a result, carbon taxes are increasingly being implemented worldwide to curb carbon dioxide emissions. Technologies that can capture carbon dioxide effectively and with a low parasitic load on the system will enable any operator emitting carbon dioxide to generate financial savings while contributing to the preservation of our environment.

Many processes exist on an industrial scale that capture carbon dioxide, but all of these processes are extremely energy-intensive. The main reason these processes are so energy-intensive is due to the batch or cyclic nature of the processes. Changing the temperature or pressure in the carbon dioxide capture system requires large amounts of energy to drive these processes. A continuous carbon dioxide capture process will, per definition, be more energy efficient.

This article documents the current hypothesis for developing and testing a continuous carbon dioxide capture system using Stirling Coolers as the driving force.

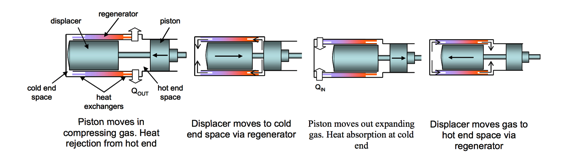

A Stirling cycle cooler is a member of a family of closed-cycle regenerative thermal machines, including heat pumps and refrigerators, known collectively as Stirling cycle machines. In any refrigeration cycle, including the reversed Stirling cycle, work input is required according to the second law of thermodynamics. This is achieved by shuttling the gas in the system backwards and forwards between the hot end and cold end spaces so that the system’s temperature during compression is, on average, higher than during expansion. As a result, the work done on the gas during compression is greater than the work done by the gas during expansion, as illustrated in Figure 1. Accordingly, the hot and cold end gas spaces are also referred to as the compression and expansion spaces, respectively. Furthermore, for operation as a refrigerator, heat must be rejected via a heat exchanger at the hot end, and heat must be absorbed from the space to be cooled via a heat exchanger at the cold end.

Figure 1. Piston and Sisplacer Movements During a Stirling Refrigeration Cycle.

Stirling engines have the advantage of being able to effectively convert heat energy as a driving force into mechanical work. Stirling coolers reverse the cycle, through supplying a mechanical driving force, heat energy is generated and removed by a heat exchanger, thus the cold end of the cylinder incrementally reduces its temperature to reach very low temperatures for relatively little work done. The figure below (source: Ray Radebaugh (NIST) 1999) illustrates Stirling cryocooler efficiency at 80K compared to traditional refrigerant, which is driven by cryogenic cooling systems.

Figure 2. Cryocooler Performance Comparison

Cryogenic Carbon Capture processes have proven to work well, regularly recovering over 95% of the CO2 content in the gas stream. Due to the relatively high sublimation temperature of CO2, this is basically a single step. Typically, the condensation or sublimation temperatures for effluent or hydrocarbon gasses are much lower, enabling a very successful separation of the CO2.

As seen in the phase diagram below, for gas pressures below 5.1 1 atm, no liquid phase for CO2 exists, and thus, it sublimates directly from gas to solid state. This enables cryogenic processes to directly freeze out the CO2 from a gas stream below 5.11 atm.

Figure 3. Carbon Dioxide Phase Diagram.

Freezing out the CO2 directly from a gas phase requires a surface for the crystals to propagate on, which is the limiting factor in the existing cryogenic carbon capture processes. This limitation gives them batch characteristics and requires energy state changes for operation. To make a continuous cryogenic carbon capture process more energy-efficient and feasible for industrial use, an infinite surface area for CO2(s) propagation would be required. Traditional heat exchanger design clearly doesn’t allow an infinite surface area, which would, in any case, require an infinite amount of energy to drive the sublimation of the CO2.

Since our aim is a continuous process that doesn’t require cyclic changes in temperature or pressure to remove the CO2(s) from the gas stream, we clearly need to think creatively about heat exchanger designs.

To ensure the heat exchanger conforms to the process requirements, we must define the processes for removing the CO2. Our organisation’s current need is to enrich a bio-gas feed stream from an anaerobic digester (removal of CO2 and water vapour). The typical composition of the bio-gas contains more than 38% CO2 and varying amounts of H2O vapour, with the main constituent being methane (CH4), less than 4% nitrogen (N2) and very low concentrations of hydrogen sulfide (H2S). Since the primary objective is the removal of CO2 and the removal of water vapour is well established, we will only focus on CO2 removal as a process constraint. This process will typically be included after the H2O vapour has been expelled from the system.

Since it has already been established that a conventional heat exchanger design will not meet our requirements, we must utilize a different approach for the required heat exchange. The author’s approach was to conceptualize a mass transfer process rather than focusing solely on energy (heat) transfer. This process also exchanges energy and provides an opportunity to separate different components based on their phase change properties.

The first process that comes to mind is a traditional scrubber column, which contacts liquid and gas streams to separate components from one stream, with the components being absorbed by the other. This process also facilitates energy exchange between the streams. If the selected liquid stream does not dissolve any components of the gas stream, nor is dissolved into the gas stream, only energy transfer will occur, functioning as a “Direct Contact Heat Exchanger.”

The liquids stream, cooled down sufficiently low, and if sufficiently dispersed (while ensuring sufficient mass to ensure heat exchange from the liquid to the gas can still occur), will increase the surface volume of the “heat exchanger” substantially, supplying a very large area for the propagation of the CO2 crystals. Consequently, CO2 crystals form on the surface of the heat exchanger liquid droplets. If the liquid stream and solid CO2 are separated, the liquid can be cooled again and recycled to the scrubber column, creating an infinite surface area for CO2 crystal propagation and enabling true continuous cryogenic carbon capture.

Since the preliminary idea for a Direct Contact Heat Exchanger (DCHE) with a theoretical infinite surface area has been established, we must conceptualize the supporting equipment to enable its successful operation.

As discussed in the above section, the preliminary equipment will be based around an absorption or scrubber column. Typically, these columns come in various arrangements depending on the intended separation of components from the different feedstocks. For the DCHE arrangement, a counter-current scrubbing column is recommended to optimize the temperature difference (DT) between the gas stream and the heat exchange liquid (similar to the concentration difference in a mass transfer process).

Since the propagation of the CO2 crystals occurs on any possible surface and can consequently create system blockages, the internal design of the scrubbing column should not include any trays and should only be composed of a single spray head (possibly multiple nozzles to maximize the liquid dispersion).

Figure 4. Proposed Scrubber Column (single head layout).

The next step would be to conceptualize the heat-exchange liquid. This approach is very straightforward. As mentioned in the preliminary constraints, the heat exchange fluid should not allow any mass transfer from the gas stream, including the CO2, to it, or allow any of its mass to be transferred to the gas stream or the CO2 stream. Further, since we will be operating the column below the sublimation temperature of the CO2, the heat exchange liquid should have a lower freezing point while remaining sufficiently viscous at the operating temperature to allow for easy pumping and dispersion.

A detailed investigation is needed to identify a suitable heat exchange liquid. Hydrocarbon ring compounds containing fluorine (such as polytetrafluoroethylene) or chlorine atoms immediately come to mind.

It is reasonable to expect that the CO2 crystals forming on the surface of the cold heat exchange liquid will create a slurry when collected. The next step is to conceptualize the separation process for the liquids and solids.