1 Introduction & Background

Small Scale LNG (SSLNG) developments are being realized by fabricating modular LNG liquefaction plants, small LNG carriers for sea freight and road tankers, and end-user skid-mounted regasification units. According to a report prepared by International Gas Union (IGU-2015 report), key observed drivers for skid-mounted LNG regasification units and other SSLNG applications are:

- Economical

- Environmental

- Governmental Policy and Regulations

- Economical: There is an energy cost advantage of LNG over alternative energy sources for end-users. An example is given in the figure below for the use of LNG as fuel compared to diesel for domestic or commercial diesel power generators

Source: Triennium Work Report – SS LNG – IGU 2015

- Environmental: SSLNG can bring attractive environmental benefits to gas production by preventing flaring and using gas where pipeline laying is uneconomical. Further, end-customer usage of LNG for transport/power & heating generation/cooling is environmentally friendly compared to alternative fossil fuels. This promotes the reduction of CO2, SOx, NOx, particles and noise emissions.

LNG is increasingly being used as a clean energy source than coal and oil because it is cheaper and achieves clean fuel transition objectives and regulatory incentives. Natural gas obtained as Regasified-LNG (RLNG), like processed natural gas from underground gas reservoirs, emits approximately 20%–30% less greenhouse gas than diesel or gasoline. RLNG has an additional advantage for metropolitan usage as it emits 50% less greenhouse gas than coal when generating electricity or used for heating.

Source: US EIA-Natural gas CO2 emissions compared with other fossil fuels.

- Governmental Policy & Regulations: Government decisions promoting the private sector to increase energy independence for a country or region by developing an alternative energy supply.

Skid-mounted LNG regasification units can help solve utility supply issues that are becoming a challenge for high rise buildings constructed in metropolitan areas. Most electricity transmission and distribution networks supplying electricity to metropolitan areas are already stressed during peak summer or winter. When modern skyscrapers are planned in such a metropolis for efficient land utilization, the associated problems include the supply of electricity, water, drainage system, waste disposal, and the like.

The demands placed on utility management of a modern skyscraper are constantly increasing. This has become more challenging as a high level of safety and flexibility throughout the project’s entire life cycle are required. Under clean energy transition initiatives, integration of renewable energies and low costs are also common demands under planners’ consideration during the development of a high-rise building.

2 Utility Energy Requirements for Skyscrapers

The Council of Tall Buildings and Urban Habitat[1] (CTBUH) has published a paper which states that tall buildings designs should be compatible with surrounding developments to create harmony with urban landscape, patterns, morphology, scale, streetscape, urban character and city skyline. The architectural design guidelines must complement the Master Planning (balancing economic, social, transportation, housing, utilities, infrastructure, etc.) and Zoning Regulations (specific aspects like building heights, setbacks, open spaces, service lanes, etc.).

In modern planning, the demands on a high-rise building are not simply split up among the individual installations but have to be coordinated. An optimum solution is created from the networking of the individual requirements. Tall buildings are best designed by integrating three distinct parts into a single whole. These parts are:

- Base (including foundations)

- Shaft (also called middle portion distinct in architecture and usage from the base)

- Top (mostly used for the provision of roof-top mechanical or telecommunications equipment, signage, and amenity spaces)

This article focuses on providing energy (gas and electricity) related utilities for the operational and occupational needs of a residential/commercial tall building. Challenges related to the coordination of individual electrical installations, such as heating, ventilation, air conditioning and refrigeration, fire protection, protection against burglary, building control system and power distribution, will be discussed. The equipment required is selected in compliance with the relevant standards (VDE, IEC, ANSI or ISO as applicable).

According to the paper[2] published by CTBUH, starting from the environmental consciousness of 1997, a growing number of tall buildings designs are going beyond the previous norm in terms of reducing energy consumption – Fifth Energy Generation Tall Buildings. An early tall building design that significantly reflected new environmentally conscious principles was the Commerzbank in Frankfurt. This building incorporated a high degree of energy-reducing design strategies and technologies like:

- A full building height central atrium, providing natural lighting and ventilation to internal office spaces.

- The use of large, open sky-gardens to further increase daylight penetration to office areas.

- A façade design that allows for natural ventilation for over half a year via operable windows.

- A water-based cooling system of chilled ceilings.

A major consideration in the Fifth Energy Generation Tall Building design is a departure from total reliance upon air-conditioning to strategies that utilize natural and mixed-mode ventilation where climatic conditions allow. Such design allows for natural ventilation of the building for almost 70% of the year, thereby reducing air-conditioning energy use.

The most important and recent development related to Fifth Energy Generation Tall Building is on-site energy generation. On-site energy generation from renewable sources (wind turbines) was successfully exhibited in Bahrain World Trade Center in Manama. The Bahrain WTC is a 240 m high twin tower complex having 50 floors and was completed in 2008.

Pearl River Tower, located in Guangzhou, China (constructed in 2006 – 2011), is a green skyscraper designed by Skidmore, Owings & Merrill. This tall building has a height of 309 meters with 71 stories. It is claimed to be the most energy-efficient super tall tower building in the world. The design approach included four important interdependent energy source and utilization aspects:

- Reduction in the amount of energy consumed.

- Absorption of energy through the utilization of the natural and passive energy sources that pass around, over and under the building’s envelope

- Reclamation of the energy already resident within the building at any point in time – harvesting and reusing inherent energy over and over again

- Generating electricity from a “microturbine” gas turbine generation technology enables power generation more efficiently than grid supply.

The micro-turbine generation technology originally designed for Pearl River Tower provided the ability for the building to produce clean power in an efficient and environmentally responsible manner. The on-site micro-gas turbines, each generating 65 KW of power, have an overall efficiency exceeding 80% – significantly outperforming the electric power utility grid efficiency of 30 – 35%. The higher efficiency design was achieved through the interdependency concept – hot exhaust from the gas turbines as an auxiliary heat source for the building for functions such as water heating and absorption cooling. Each machine of micro gas turbines series of 50 (daisy-chained together to generate 3 MW power) was designed to be close to the size of a large bedroom wardrobe, was safe with low noise and vibration-free characteristics. However, the original design was changed due to the intermittent requirement of full power load throughout the year. Financial payback was justifiable only when they were grid-connected to sell surplus power to the grid – which was denied. However, these compelling components of low energy, sustainable design were retained for later installation whenever local Guangzhou infrastructure becomes available to sell surplus generated power.[3]

3 Skyscrapers Energy Supply Through Skid Mounted LNG Regasification Units

Although renewable energy technologies are abundantly being used to improve skyscrapers’ energy performance, the intermittent nature of such energy sources makes it an essential requirement to make available grid electricity for off-setting low or zero renewable power generation periods. This dependence on inefficient grid supplies can be eliminated by technologies supporting on-site power generation – micro gas turbines coupled with fuel supply from skid-mounted LNG regasification units.

Learning from the design alteration of Pearl River Tower building, from the micro gas turbine to wind turbine due to non-acceptance of a local distribution company to accept surplus power, systems can be built that caters for inherently balancing the power generation with power usage. This can be achieved through various applications related to other utility provisions like wastewater recycling and electric vehicle charging stations.

Skid-mounted LNG regasification systems can supply natural gas for on-site energy generation through efficient, low noise and safe micro gas turbines. Such micro gas turbines can be daisy-chained to produce any power generation needs as per site conditions. Provision of one or more LNG truck tankers can be arranged to match the site’s gas supply needs and storage requirements. Following is a suggested combination of economically viable configurations for utility supply to skyscrapers:

- Gas-powered LNG Road Tankers – Environmentally friendly mode of LNG transportation with the additional advantage of minimizing boil-off gas

- Skid-mounted LNG Regasification system – Reduction in energy consumed through minimized losses in natural gas transmission and distribution through pipeline. Additional reduction in electricity generation for the locality supplied through grid due to reduction in grid electricity supply losses for the skyscraper.

- Efficient Building Envelop – Absorption of energy through the utilization of the natural and passive energy sources that pass around, over and under the building’s envelope

- Designing for Energy Consumption Cycles – Reclamation of the energy already resident within the building at any point in time. Making provisions for off-peak power demand usage like wastewater treatment, shifting of some equipment from gas usage to electricity usage, installation of electric vehicle charging stations and the like

- Generating electricity from a “microturbine” gas turbine generation technology enables power generation more efficiently than grid supply. These daisy-chained turbines can be periodically switched on and off depending upon the load requirement.

- Making provision for the sale of electricity to the local grid whenever surplus electricity can be made available to the grid economically

4 Brief Description of RLNG Supply Chain – Based on Skid Mounted Regasification

Complexity, lead-time and costs involved in large scale LNG supply chains make it difficult to efficiently handle environmental concerns and imbalances of natural gas resources across the globe. SSLNG as an alternative solution can produce LNG at remote locations with available technologies to conveniently transport the product at the point of consumption, regasify on-site, and use natural gas-fired plants. Using LNG in its liquid form without undergoing the regasification process enables small-scale business developers to build more profitable business models. Advantages of SSLNG over large-scale LNG projects are lower CAPEX, shorter construction timelines and shorter payoff periods.

The primary business platform for metropolitan use of regasified LNG is based on LNG trucks and skid-mounted regasification units. A 2007 World Bank report, conducted with China’s National Environment Agency, found that outdoor air pollution has caused approximately 400,000 premature deaths, and indoor air pollution has caused another 300,000 deaths. At present, China has the highest number of LNG trucks in operation globally and is the world’s largest consumer of SSLNG. The majority of this growth is in response to government regulations for cleaner fuels to help reduce air pollution.

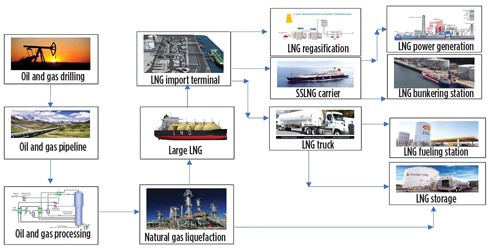

Skid-mounted LNG regasification systems for gas supply in metropolitan areas for skyscrapers depend on developing a complete supply chain. The figure below shows that it is highly capital intensive to successfully develop the infrastructure required for a complete supply chain. This supply chain includes natural gas production, gas processing facilities, liquefaction units, export facilities, LNG carriers, import terminals, small-scale LNG transportation, SSLNG remote storage facilities, skid-mounted LNG regasification systems and truck refuelling stations.

Complete LNG Supply Chain including SSLNG Supply to Metropolis

SLNG is more feasible and attractive when connected with large LNG supply chains that are independently operating more profitably. Since SSLNG, as a connected supply system, requires less capital than large-scale LNG facilities, a greater number of small-scale business developers can enter the market without undue risk-taking.

Thus, a successful gas supply model for a metropolis skyscraper has the following essential components in the supply chain:

- Independent and multiple LNG supply commitments from various large LNG supply chains or components of supply chains like LNG land storages or sea bunkers

- Road tankers fleet for LNG transportation to the site that is fueled by natural gas (boil-off LNG)

- LNG storage tankers for on-site installation of LNG road tankers parked on-site as storage

- Skid-mounted LNG regasification units installed safely on-site

- Natural gas distribution network on-site downstream of LNG regasification unit up to skyscraper micro gas turbines and other consumption points in the building

In the end, it is essential to highlight the challenges related to the creation and maintenance of high safety standards associated with the SSLNG supply chain requiring low-temperature-rated materials for storage and transportation. Due to the implementation of such safety standards, the average shipping cost per ton of LNG is high for SSLNG, compared to large-scale LNG transportation. However, the overall design efficiency of the utility supplies to the skyscraper and smaller CAPEX costs for the SSLNG regasification system make it an economically viable and environmentally successful implementation model.

To all knowledge

To all knowledge