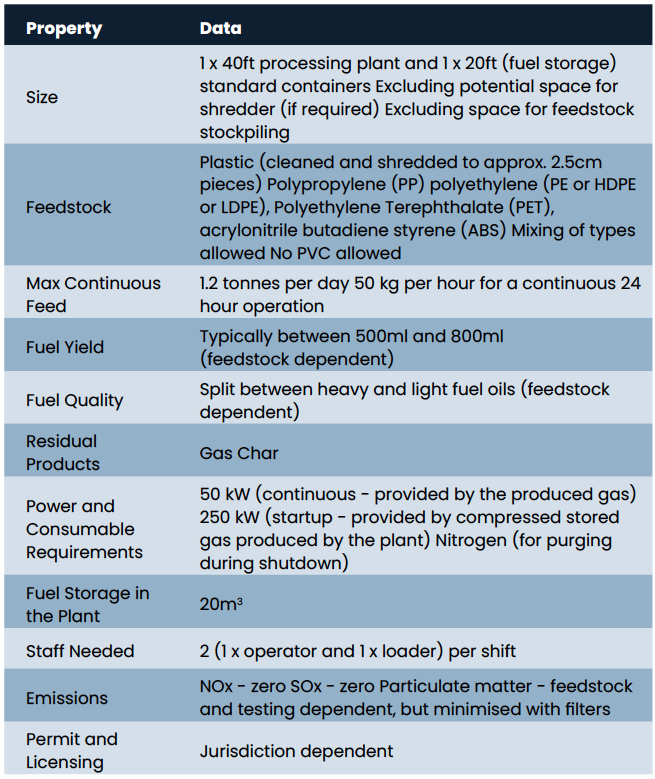

EPCM Holdings developed a modular, plastics-to-fuel-oil plant. The small-scaled plant continuously processes 1.2 tons of plastic daily and produces various fuel oils.

The resulting fuel oils can be used for power generation and fleet running or sold to bulk distributors for blending, resulting in a quick payback period and additional revenue stream.

This solution is ideal for businesses that use plastic waste as a by-product. It provides a convenient long-term off-take — be that themselves or a third party.

The modular design allows for rapid deployment with minimal site preparation and easy future relocation.

The plants are fabricated in ISO-accredited facilities in South Africa, from where they are shipped worldwide to customers.

Product Yield & Quality

The plant produces various fuel oils and residual products: gas and char.

The quality and yield of the fuels produced are feedstock-dependent. Typical yields are between 500ml and 800ml fuel oil per kg, split equally between heavy and light oils.

Our facility in South Africa can test 5kg batches to confirm the client’s feedstock yield and quality. Laboratory test results accompany the test. These results and the capex, opex and local market fuel prices provide the information to determine the resulting business case.

Technology

The plant’s technology is a small-scale depolymerisation unit that produces fuel oils through a pyrolysis reaction and a series of catalytic converters.

The plant has two main parts, one for processing and the other for storage units. The processing unit receives the shredded plastic feedstock with a lift screw for continuous feeding operation – a major efficiency improvement in batch-operated plants. At this point, a sand filter removes items like carbon, iron, earth and other nonorganic chemicals.

From here, filtered plastic oil from the reactor will be fed through an acid absorber unit, protecting the downstream equipment against accidental small amounts of polyvinyl chloride (PVC) components in the feedstock.

The absorber is followed by various processing equipment, including catalytic converter reactors, coolers and knock-out drums, which split the products into fuels.

Finally, the resulting fuels are separated into heavy and light oils and stored in a 20m3 tank in the second container.

Operations & Maintenance

The plant can run 24/7 with approximately two weekly stoppages for basic maintenance.

Typical maintenance includes replacing sand filters (frequency dependent on feedstock), upkeep of rotating equipment (compressor, screw conveyor and air-coolers), and mechanical maintenance of control and relief valves.

The plant operations are handled by two staff. One for manually loading the feedstock into the screw lift hopper and the other for monitoring and controlling the plant settings and output. In developed labour markets, this process can be fully automated to reduce reliance on staff.

The continuous power requirements are 50kW, supplied by the residual gas from the plastic processing, and 250kW for startup, supplied by compressed stored gas from the plant.