1 Introduction

1.1 Pipeline Pigging System

The Pipeline pigging system involves using a device called a Pig to perform various tasks, including cleaning, maintenance, inspection, batching, and dimension checks on a new or existing pipeline. During the pigging operation of an existing pipeline, pipeline operations are not stopped, meaning the pigging tool is introduced into the flow stream. It travels along the pipeline, utilising the flow and pressure of the pipeline.

It should be noted that pigging operations are performed on gas pipelines, liquid hydrocarbon pipelines, pipelines conveying waters, pipelines transporting slurries, etc.

Pigging operations are performed using Pig Traps (Launcher and Receiver), a Pigging tool and a medium for propelling the pig in the pipeline.

A pipeline may be equipped with permanent pig launchers and receivers; however, temporary launchers and receivers are common. Temporary launchers are typically used for subsea pipeline pigging. The launcher is connected to the pipeline end manifold to commence the pigging operation.

Pigging operation is a critical activity that should be appropriately planned, considering all safety and operational considerations. Several accidents have been recorded during pigging operations.

This article will emphasise pigging facilities installed within onshore and offshore platforms.

Figure 1: Arrangement of Pig Launchers and Receivers in a Facility

2 Pigging Pigging System: Operation Major Component

2.1 Pig Traps

Pig traps are static equipment utilised to introduce pigging tools into a pipeline and receive the pigging tool at the other end of the pipeline. There are two types of Pig Traps

2.1.1 Launcher

The launcher is the equipment used to feed the pigging tool into the pipeline. It comprises a door or end closure, which can be opened and closed. There are nozzle connections on the Launcher. These will be discussed in later sections of this article

2.2.2 Receiver

The Receiving Trap is stationary equipment used to receive the launched pigging tool. It generally looks almost the same as the launcher except for some configuration changes. The Receiver is equipped with a door or an end closure. This is where the pigging tool and cleaning debris are received. The receiver has nozzle connections for piping and instrumentation connections, which will be discussed in detail in further sections of this article.

2.2.3 Pig Trap Orientation

Generally, a pig trap may be installed in the orientations below. The major factor dictating the type of orientation is the space available. In offshore applications, riser location and entry position into the platform are key factors.

2.2.3.1 Vertical Launcher

A vertical launcher is specifically for launching with a short neck and a concentric reducer. These launchers’ orientations are used in offshore platforms where space availability is critical. Also, the pipeline riser is vertical, so in some cases, the vertical configuration is the best by aligning the Launcher to the Riser

Figure 2: Vertical Pig Launcher Installed on Offshore Platform. Launcher

2.1.3.2 Vertical Receiver

Vertical receivers are specifically for receiving with a longer neck and a concentric reducer. They are not very common. However, they are used mostly in offshore applications. Just like the vertical Launchers, they are more applicable with space limitations. It should be noted that some companies prohibit the use of vertical pig receivers.

2.1.3.3 Horizontal Launcher

These types of Launchers are specifically for launching in the nearly horizontal position. They have an eccentric reducer (Flat on the Bottom) to ensure the pig enters the neck in the correct orientation. These launchers are the most commonly seen in all facilities. They can be conveniently installed onshore and on offshore platforms where there is no space limitation.

It should be noted that some Companies’ regulations require that horizontal Pig Launchers should slope downward toward the pipeline; the essence of this slope is to aid liquid draining from the barrel. As per SHELL DEP 31.40.10.13-Gen, the minimum slope angle required for a pig launcher is 3 degrees

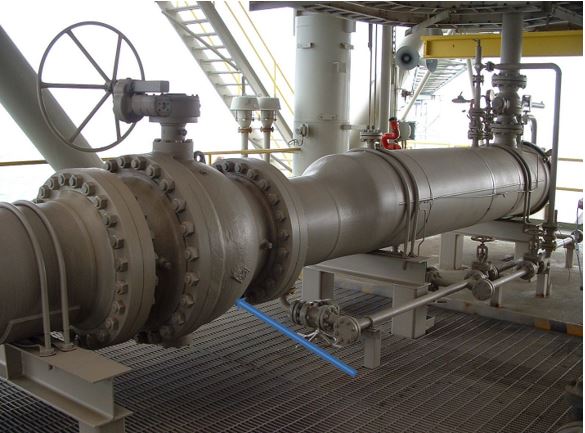

Figure 3: Horizontal Gas pipeline Pig Launcher

2.1.3.4 Horizontal Receiver

These Receivers are specifically for receiving pigging tools in the horizontal position. They could have a concentric or eccentric reducer, but the eccentric reducer type is the most common.

They are the most common reducers, and they can be found on offshore platforms and onshore facilities.

Some companies’ regulations require that horizontal Receivers should slope downward toward the end closure; the essence of the slope is to aid liquid draining from the barrel. As per SHELL DEP 31.40.10.13-Gen, the minimum slope angle required for a pig launcher is 3 degrees

Figure 4: Horizontal Gas Pipeline Pig Receiver

2.2 Pipeline Pigging Tool

A pipeline pig or pigging tool is a device driven through a pipeline by the flow of the fluid (flow rate and pressure) within the pipeline that is used to perform various internal activities. These activities include cleaning, separation of pipe fluids (batching), internal inspections, dimension checks, etc. Various types of pigging tools are available and have various applications. They may be grouped based on function, construction material and applications. Some examples of pigging tools are listed below.

- Foam Pigs

- Spherical Pigs (Spheres)

- Steel Mandrel pigs

- Solid Cast Pigs

- Geometry/Calliper pigs (Inline Inspection Pigs (ILI))

Figure 5: Pigging tool with Brushes Utilised for Cleaning a Subsea Pipeline offshore

3 Pipeline Pigging System: Operations and Applications

As stated in section 1.0, pigging operations are performed for specific reasons. Some pigging operations are highlighted below

3.1 Cleaning Operations

This is one of the major pigging operations. It is used for existing pipelines, both in-service and newly constructed pipelines, that have debris from welding and construction activities.

Pipelines conveying fluids (Liquid and gas) accumulate debris over time, which may have resulted from the fluid transported, internal corrosion, Wax formation, etc.

Pipelines usually have debris due to welding and other activities during pipeline construction.

Debris can be effectively removed by sending a suitably selected pig through the pipeline. For an in-service pipeline, the flow operation conveys the pig across the entire pipeline length to the receiver.

For a new pipeline under construction, compressed air could propel the pig across its entire length prior to commissioning.

Various types of pigs could be used for this operation, including Steel Mandrel and solid cast pigs. However, Steel Mandrel and Solid Cast pigs perform much more efficiently.

3.2 Pipeline Dewatering

Dewatering entails removing water from a pipeline. This activity is usually performed after a pipeline has been hydrotested. After the hydro test, all the water in the pipeline cannot be drained due to the varying elevation along the pipeline. A Pig is sent into the pipeline to push most of the water out. Foam pigs are mostly used for this task.

Dewatering is performed by propelling a pig through the entire pipeline. Compressed air at appropriate pressure drives the pig while the trapped water in the pipeline is pushed out.

It should be noted that this activity may be repeated more than once to ensure that the pipeline is thoroughly dewatered.

Figure 6: Foam Pig used for Dewatering Operation

3.3 Geometry or Calliper Pigging

This is another pipeline pigging operation performed during pipeline construction or after pipeline sections are replaced. It may also be carried out on the suspicion of pipeline defects.

These tools can effectively measure pipeline internal bore diameter, depth of dents, bend radius, ovalities, deformations, and girth weld, among other things.

This activity aims to detect pipeline imperfections exceeding the maximum code allowable. Geometry pigs may be propelled using compressed air.

This tool has an inbuilt global positioning system, which helps to accurately locate any measured data.

3.4 Batching Operation or Sealing Operation

There are pipelines designed and constructed to convey more than one product type (multi-product pipelines). A pipeline can be designed to transport ATK (Aviation Turbine Kerosene) and DPK (Dual-Purpose Kerosene), Premium Motor Spirit (PMS), Automotive Gas oil (AGO), etc.

These products are transported in batches, i.e. ATK before DPK.

The operation involves sealing pig to form a barrier between the transported fluids. This pigging operation uses the system flow parameters (flow rate and pressure) to propel the pig through the pipeline. The interface zone between batched fluids is sent to a slop tank at the reception facility for further process activities.

Foam pigs and other solid pigs are ideal for batching operations.

3.5 Pipeline Inspection Pigging Operation.

This is an advanced type of pigging operation performed using inspection tools, also known as smart pigs or in-line inspection pigs.

These pigs are used to acquire information, especially about the pipeline’s corrosion rate. They can also measure the pipeline’s curvature and diameter (internal and external).

As the pigging tool is propelled along the pipeline, the characteristics of the pipeline are measured. These results are further interpreted and analysed to obtain various data.

This method of pigging is utilised for the in-service pipeline; the pigging activity utilises the fluid flow parameters (flow rate and pressure)

Generally, two types of inspection methodology are employed, as discussed below:

3.5.1 Magnetic Flux Leakage (MFL)

MFL pigging tools use magnetism to detect wall thickness loss in pipelines. A very strong magnet is used to magnetise the pipe wall. Metal loss in the pipe wall due to corrosion or other factors will cause a change in the induced magnetic field. Changes in pipe wall thickness can be sensed using a detector; hence, corrosion or loss of metal can be detected.

The collected data can be further analysed to obtain other data, such as bend angles. Magnetic flux leakage pigs can be utilised for both gas and liquid pipelines.

3.5.2 Ultrasonic Inspection

This method uses ultrasound to measure pipeline wall thickness. As the pig is propelled through the pipeline, a transducer transmits signals perpendicular to the pipe wall surface. The transducer receives these signals for each pig position along the pipeline. The signal received is from the pipeline’s internal and external walls.

The time taken to receive the signal is further analysed to determine the pipeline wall thickness.

It should be noted that ultrasonic pigs are applied to the liquid pipeline system.

A major advantage of Ultrasonic inspection over Magnetic Flux Inspection is its ability to measure pipelines’ higher wall thickness.

4 Pipeline Pigging System Philosophy

A pigging philosophy should be developed during the pipeline planning stage. The philosophy shall cover activities including pipeline cleaning and inspection of pipeline wall thickness. Requirements for pigging equipment are stated in section 864.2.3 of ASME B31.8. Some of the considerations for developing the philosophy are stated below.

4.1 Pigging Philosophy Considerations

4.1.1 Planned Type of Pigging Operation

This is one of the key factors to consider when developing a pipeline-pigging philosophy. It is a function of the fluid characteristics (Corrosive or non-corrosive) and other factors. Pipelines transporting non-corrosive fluids will be less subjected to internal corrosion; hence, the need for intelligent pigging is less than for pipelines transporting corrosive fluids.

Pipelines transporting sensitive fluids such as Aviation fuel require regular checks to detect fuel contamination due to corrosion and debris. This is usually tackled by selecting appropriate pipeline material and inspection plans during the pipeline planning stage.

The operations to be performed over a period of time should be well-detailed in the philosophy and judiciously implemented during the pipeline’s operation phase.

4.1.2 Frequency of Pigging Operation

This is usually considered during the development of the pigging philosophy. The frequency of pigging operations varies depending on the fluid characteristics transported.

Pipelines transporting corrosive fluids have a higher inspection frequency than pipelines transporting non-corrosive fluids.

Pipelines used for Batching operations (multi-product pipelines) require frequent use of batching pigs. This should be carefully planned based on the volume of fluid transported and the frequency of transporting a different product.

4.1.3 Selecting Appropriate Pigging Tool

There are many manufacturers of pigging tools; however, selecting a manufacturer or two is important during the pipeline planning stage. It is important to select manufacturers because different vendors have different specifications for their pigging tools. The pigging tool specification may include the following:

- The length of the pig

- Pigging tool operational weight

- Pigging tool transportation weight

- The maximum inspection ranges of the pigging tool

- The velocity range required for the pigging tool

- Maximum and minimum operating pressure for the pigging tool

- The product temperature range the pigging tool can be used

Considering the above requirements, a particular pigging tool is selected to satisfy the fluid properties, and the pipeline is designed to suit the pigging tool’s dimensional requirements.

4.1.4 Planning for Debris Handling

The quantity of debris expected from the pipeline pigging operation should be estimated when preparing the pigging philosophy. Appropriate provisions for handling and disposing of this debris should be well spelt out.

4.1.5 Pig Tracking

It is paramount that when a pig is launched, its location is known. There are instances when pigging tools get stocked in a pipeline. It is very important to know the actual location of the tool to proffer remedial actions if a pig does not arrive at the proposed destination. Smart pigs are easily tracked because they have an in-built monitoring system that can be used to determine the pig’s location. The pigging tool has inbuilt transmitters that send a signal at a variable frequency to a receiving system.

4.2 Factors Affecting Pigging Tool Selection

Several factors affect pigging tool selection; some will be highlighted in this section. During the pipeline planning stage, pigging should be a critical part of the project that must be properly analysed.

4.2.1 Pipe Size

When selecting the pigging tool, the size of the pipeline is a major factor. Intelligent pigs have minimum and maximum operational pipeline sizes that can operate effectively.

Also, the bigger the pipeline, the bigger the tool. The size of the tool affects the operational effectiveness of attachments such as brushes. Larger tools are subject to higher stresses.

4.2.2 Pipeline Length

Pipeline length varies, and it affects the pigging tool’s operational efficiency. Foam pigs used on long pipelines are subjected to more frictional wear.

Smart pigs usually have a maximum specified pipeline length that can be covered. Also, due to the friction between the pigging tool and the pipeline wall, more heat is generated during the pigging of long pipelines. Therefore, selecting a tool that satisfies the pipeline length requirement is paramount.

4.2.3 Pig Handling Area Available

During pigging operation, space is required to convey the pigging tool close to the barrel, above the barrel, for vertical launchers and receivers. Due to their size, space requirement is more critical when pigging with smart tools. Usually, the pig tool manufacturer specifies the minimum area required for pigging operation. Also, the handling area should consider the radius required to operate the pig trap end closure safely.

Therefore, it is necessary to create the space required for pigging operation around the trap or to ensure that the selected pig tool can be successfully operated within the available space.

4.2.4 Bend Radius

This is a major factor that affects pigging when smart pigs are used. Smart pigs are longer than conventional cleaning and batching pigs. They are flexible to navigate pipeline bends, however, there is a limitation in their flexibility as they can only pass through bends wit radius large enough. Usually, 5D bends provide passage for medium pipeline-size pigging tools; however, pipelines are built with 3D bends and even 1.5D elbows. It is, therefore, very necessary that a selected pigging tool must effectively navigate through all the pipeline bends.

Also, during pipeline planning, the bend used should be properly selected to ensure it can allow the passage of the selected pig tool.

Figure 7: Installed Pipeline 3D Bends

4.2.5 Medium Used to Propel the Tool

Pigging tools can be used for both liquid and gas mediums. However, a specific tool can only function efficiently in a medium. So, the tool selection should consider the fluid transported or that will be utilised to propel the pig.

4.2.6 Pipeline Inline Components

Inline Components such as valves and Tees are major factors affecting a pipeline’s inability. There are instances where the wrong valves are installed on pipelines. All piggable pipeline valves shall be full bore; however, several reduced bore valves have been encountered during pigging operations. The implication is that the pig will be trapped on the valve.

Figure 8: Piggable Pipeline Full Bore Valve

Also, all branch connections to a pluggable pipeline using Tees shall be appropriately specified. Only barred Tees shall be utilised for pluggable pipelines. However, the use of barred Tees is limited to branch connection size, which is a function of company and code requirements.

The table below shows the requirements for branch connection to a pipeline that may be adopted as per ExxonMobil GP-59-01-05 (Pigging Systems).

Table 1: Barred Branch Connection Requirement

5 Layout and Components of a Pipeline Pigging System

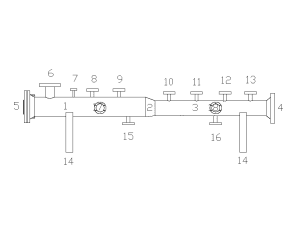

In this section, I will try to itemise and explain each component of a pigging system. The pictures below show the 3D view of a Pig Launcher and Receiver and the schematic of a Pig Trap. It should be noted that there might be variation in the configuration, a number of attached nozzles depending on the fluid transported and the design philosophy. Also, take note of the Kicker line location for Launcher, it is at the back close to the end closure while for a receiver it is at the front close to the reducer. This is one of the major differences between a Launcher and a Receiver.

Figure 9: 3D Model of a Gas Pig Receiver

Figure 10: 3D Model of a Gas Pig Launcher

Figure 11: Generalized Schematic of a Pig Launcher

See below the names of each attachment to a pig Trap.

- Major Barrel

- Reducer

- Minor Barrel

- Nozzle Attachment to Pig Trap Valve

- End Closure or Door

- Kicker Line Nozzle Connection

- Pressure Indicator Nozzle Connection

- Major Barrel Vent Line Nozzle Connection

- Relief/Vent Line Nozzle Connection

- Pig Signaller Nozzle Connection

- Pressure Indicator Nozzle Connection

- Minor Barrel Relief/Vent Line Nozzle Connection

- Purge Line Nozzle Connection

- Pig Launcher Support

- Major Barrel Drain Nozzle Connection

- Minor Barrel Drain Nozzle Connection

- Equalization or Balance Line Nozzle Connections (Major Barrel)

- Equalization or Balance Line Nozzle Connection (Minor Barrel)

Following the numbering system above, l will briefly explain each component and others not part of the list above.

5.1 Major Barrel

The major barrel is a pipe with a diameter greater than the diameter of the minor barrel. It is usually bigger to facilitate easy loading of the pig into the launcher or easy unloading of the pig from the Pig Receiver. Selecting the major barrel size is critical to an effective pigging operation. As per SHELL DEP 1.40.10.13-Gen pipelines of sizes smaller than NPS 20”: the major Barrel nominal diameter should be 50 mm (2 in) larger than the pipeline’s nominal diameter.

Also, the DEP requires pipelines with nominal diameters DN 500 (NPS 20) and larger to have a major barrel’s nominal diameter 100 mm (4 in) larger than the pipeline’s nominal Diameter.

Also, when specifying the major barrel size, the internal diameter of the barrel should be considered. When the barrel is made of low-grade pipe material, it will result in a very thick barrel that may be close in internal diameter to the pipeline, which can affect pipeline pluggability.

5.2 Reducer

The reducer is the connection interface between the Pig trap’s major barrel and the minor barrel. It is welded to both barrels. Eccentric reducers are recommended for horizontal pig traps; however, concentric reducers may be used depending on client requirements. Concentric reducers are recommended for vertical pig launchers.

The dimensions of the reducers (concentric and eccentric) shall be obtained from ASME B 16.9 (Factory-Made Wrought Buttwelding Fittings) or other generally acceptable codes and standards.

5.3 Minor Barrel

This is the smaller diameter section of the pig trap. It usually has the same outside diameter as the pipeline.

The internal diameter of the minor barrel should be the same as that of the pipeline, or minimal variation is permitted. When there is a significant difference between the internal diameter of the minor barrel and the pipeline, the pig may be unable to exit the barrel for launchers or enter the barrel for receivers.

SHELL DEP stipulates that transitions in the internal diameter of the barrel due to wall thickness variation greater than 2.4 mm shall be tapered to a maximum angle of 14o to the pipe axis to allow the smooth passage of a pig.

5.4 Nozzle Attachment to Pig Trap Valve

The nozzle is the last component downstream of the pig launcher or the first component upstream of the pig receiver. It should be noted that in instances when pig traps are welded to pipelines, the nozzle shall be eliminated from the drawing,

An isolation valve shall be installed at the transition from the pig trap to the pipeline. For flanged valves, the nozzle is the connecting element to the valve. The nozzle shall be appropriately rated to the design pressure and temperature. Nozzle dimensions may be obtained from ASME B16.5 (Pipe Flanges and Flanged Fittings NPS 1/2 Through NPS 24) and ASME B16.47 (Large Diameter). Steel Flanges NPS 26 through NPS 60 Metric/Inch Standard) or other applicable codes and standards.

5.5 End Closure or Door

The end closure or door is the only access to feed the pigging tool into the launcher or retrieve the pigging tool from the receiver. The end closure shall be welded to the major barrel. The end closure is the most critical part of the pig launcher because if the closure opens during the pigging operation, it can result in a serious accident. The end closure is usually made of a material compatible with the barrel. End closure is generally of quick opening type with an inbuilt safety interlock system to prevent the door/closure from opening during pigging operation. There are different types of closures, some suitable for vertical pig traps while others for horizontal pig traps. The end closure is mostly equipped with hinge assembly for horizontal installation and davit for vertical installations.

As stated in section 404,7 of ASME B31.4, Quick opening closures shall be equipped with safety locking devices in compliance with Section VIII, Division 1 UG-35(b) of the ASME Boiler and Pressure Vessel Code. However, closures can be designed to other codes and standards, including PD 5500 / EN 13445.

Figure 12: Hinged Type End Closure

5.6 Kicker Line

The kicker line connects the major barrel to the bypass line. It allows fluid diversion from the bypass line to the barrel to launch the pig or to receive the pig on the receiver. It should be noted that the kicker line position on a launcher barrel is at the back close to the end closure, while for the receiver, the kicker line is at the front of the major barrel close to the reducer.

Figure 13: Kicker Line Location for Launcher

Figure 14: Kicker Line Location for Receivers

5.7 Pressure Indicators

Pressure indicators are a key component of a pigging system. All pressure gauges should be properly calibrated before commencing pigging operations. There may be a pressure indicator mounted on the major and minor barrels; however, there are instances when one pressure indicator is used. With the indicator properly installed, the operator can check if the barrels are pressurised during pigging operations.

5.8 Vents/Relief Lines

Vent/Relief lines are critical components during pigging operations and act as safety devices. The vent valve is manually opened before the operation commences.

The Relief valves open if the barrel pressure exceeds a set point. One of these valves is usually installed on the major and minor barrels, respectively.

Figure 15: Relief Lines

5.9 Pig Signallers

Pig signallers are alert devices installed on the minor barrel, on or before the minor barrel. They indicate the passage of a pig. They may also be installed at appropriate locations along the pipeline. When a pig is launched, the barrel end closure is usually closed, so there is no way to know that the pig has left the barrel without installing a signaller. In most cases, launchers have one installed on the minor barrel and another installed downstream of the pig trap valve. The passage of the pig will generate a signal. Also, without a pig signaller, it will be difficult to detect if the pig has arrived at the receiver. This implies that installing at least one pig signaller on the receiver minor barrel and or upstream of the receiver valve is mandatory. There are two types of pig signallers: Intrusive and the non-intrusive type. The intrusive type is a mechanical device requiring a hole to be bored into the pipeline and a flange or nipple connection to be installed. The Pig Sig is then installed on this connection.

Unlike intrusive pig signallers, non-intrusive pig signallers can be quickly installed and removed from the pipeline. They are strap-on devices equipped with sensors. The non-intrusive pig signaller can detect the location of the pig as it approaches. They do not require boring a hole in the pipeline. The passage of a pig is indicated by light flashes in colour.

5.10 Purge Lines

This is a small line equipped with valves (a Check and an isolation valve) and a blind connection for introducing inert gas into the barrel when the pig is not in operation.

5.11 Pig Trap Supports

The supports are the load-carrying member of the trap. They carry the dead weight of the trap when they are not in use and carry both live and operational loads.

Horizontal pig traps are supported on saddles, usually two, while vertical pig traps are supported on trunnions resting on the offshore platform framework.

5.12 Drain Lines

As the name suggests, these lines drain liquid content from the pig trap. Usually, one drain line is connected to the minor barrel and another to the major barrel. These two lines can be commingled into one and routed to a closed drain system.

5.13 Equalization or Balance Line

An equalization line connects the major barrel to the minor barrel. The equalization line creates pressure upstream and downstream of the pigging tool in the pig trap.

For launchers, a balanced line shall be provided to enable filling and pressurising of the barrel on both sides of the pig, while for receivers, a balanced line shall be provided to prevent any possible pressure differential across a received pig

Figure 16: Pressure Equalization Line on a Pig Launcher

5.14 Bypass Line

The bypass line is the major service line that connects the pipeline to upstream or downstream facilities such as tank farms, compressor stations, pump stations, reception facilities, etc. This branch line connection to the pipeline is usually located downstream of the big launcher valve or upstream of the pig receiver valve. The kicker line takes its fluid source from the bypass line.

Figure 17: Bypass Line

5.15 Valves

There are no piping networks without installed valves; however, valve type selection must be carefully performed when it comes to pigging system design. Various valves are installed in the pigging system; however, I will explain briefly some requirements for consideration.

5.15.1 Pig Trap Valve

The pig trap valve isolates the pig trap from the pipeline system when it is not in use. The valve must be in good working condition. Some clients require that a double block and bleed valve be installed to achieve this isolation.

The pig trap valve(s) shall be a full-bore, tight shut-off ball valve or through-conduit gate valve to permit the easy passage of pigs.

Also, the minimum internal diameter of the valves shall be consistent with that of the pipeline.

5.15.2 Bypass Valve

This valve is located close to the branch tee connection to the pipeline. It is installed to isolate the pipeline from facilities connected to it. Any of the following valves can be installed as a bypass valve: a tight shut-off ball valve, a pressure-balanced plug valve, or a through-conduit gate valve.

5.15.3 Kicker Valve

This is the valve installed on the kicker line. The gradual opening of this valve bypasses fluid flow from the bypass line to the barrel. This valve should be installed as close as possible to the bypass line.

To isolate the bypass line from the barrel, a tight shut-off ball valve, pressure-balanced plug valve, or through-conduit gate valve may be installed.

5.15.4 Drain Valves

These are mostly manually operated valves. Their opening permits the draining of liquid content from the pig trap. Tight shut-off quarter-turn ball or pressure-balanced plug valves can be used for this purpose. When debris is expected, the use of a ball valve and gate valve should be carefully evaluated.

5.15.5 Vent Valves

These valves are installed on the vent lines. They are used to depressurise the pig traps manually. Tight shut-off ball valves, gate valves or plug valves can be used. A globe valve is very suitable for gas lines.

5.16 Pig Drip Tray or Drip Pan

A drip tray shall be provided under the end closure permanently or temporarily. The tray may be provided with appropriate piping to a closed drain system if a high volume of liquid is anticipated. Vertical launcher installed on the offshore platform usually has the tray installed concentrically or eccentrically around the barrel. When the end closure is open, especially for liquid pipelines, there is the possibility of liquid draining out. The tray collects the liquid for onward transport to the drain system.

5.17 Lifting System/ Davit

This is required, especially when the pigging operation involves intelligent pigs. These pigs are heavy and cannot be easily lifted. In most cases, a Davit of appropriate rated capacity is installed to facilitate lifting the pigging tool.

5.18 Pig Trays

A Pig Tray is mechanical equipment that facilitates the easy loading of the pig into the Launcher or the easy unloading of the pig from the receiver. The height of the tray should be designed to align with the bore of the major barrel. A hand, Davit, or any other mechanical device may be used to push the pig into the barrel.

Sometimes, the trays may be incorporated into a Trolley that can be used to convey the pigging.

Pig trays are not applicable to vertical launchers and receivers; the only requirement is a means of transporting the pigging tool.

Figure 18: Pig Trolley with Installed Tray

6 References

ASME B16.5: Pipe Flanges and Flanged Fittings NPS 1/2 through NPS 24

ASME B16.47: Large Diameter Steel Flanges NPS 26 through NPS 60 Metric/Inch Standard

ASME B 16.9: Factory-Made Wrought Buttwelding Fittings

ASME B31.4: Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids

ASME B31.8: Gas Transmission and Distribution Piping Systems

SHEEL DEP 31.40.10.13-Gen: DESIGN OF PIPELINE PIG TRAP SYSTEMS

ExxonMobil GP 59-01-05: Pigging Systems

To all knowledge

To all knowledge