Summary

Enhanced oil recovery (EOR) is crucial to recovering oil from mature reservoirs. This step can be broken down into thermal or non-thermal processes. Thermal approaches include injecting hot water or steam, electrical heating, and in-situ combustion. Likewise, non-thermal can be split into chemical or gas injection methods. For the extraction of light or medium oils from aging reservoirs, gas injection EOR techniques use hydrocarbon gases due to their miscibility and higher recovery rate. Unfortunately, these hydrocarbon gases have become scarce as they are in high demand for domestic and commercial purposes. Gases like hydrogen sulfide, carbon dioxide, and nitrogen have been used in recent EOR projects because of their promising potential in gas injection processes. Injected gases can improve oil recovery through several mechanisms, including reducing viscosity, swelling, and displacement. The amount of oil displaced depends on microscopic and macroscopic efficiencies affected by factors like interfacial tension and the mobility ratio. A comparative analysis of different EOR injection gases was presented for their advantages and limitations in carbonate reservoirs. Nitrogen, which can be supplied to injection sites through pipelines or separated from air, was discussed as a potential EOR gas. Nitrogen has the advantage of being readily available, but its low overall percentage recovery of oil and high capital costs are significant limitations. However, further research on nitrogen-based EOR techniques could be conducted to explore its potential for future EOR projects around the globe.

Introduction

In the EOR processes, selecting an appropriate injection fluid is crucial to provide the mechanical or thermal energy that is either not naturally present or has decreased over time. Several objectives can be achieved using a variety of injection fluids, which can significantly enhance the overall efficiency of the EOR process. For instance, interfacial tension, capillary forces, and viscosity can be reduced. On the other hand, capillary numbers, mobility control, and oil swelling can be increased. Moreover, changes to the rock wettability in the reservoir can also be achieved by injecting various fluids.

It is important to note that the injection of gas as a displacing fluid is one of the widely used EOR methods. The gas injected into the reservoir displaces the oil, and the displaced oil is then recovered from production wells. This process can be further optimized by adjusting the injection rate and pressure depending on the geological characteristics of the reservoir. Additionally, the injected gas’s composition can be modified to achieve the desired results.

The present article discusses how selecting and injecting an appropriate fluid (like nitrogen gas) can lead to several favorable conditions. It is essential to use a suitable method depending on the geological characteristics of the reservoir. The injection of gas as a displacing fluid is one of the widely used EOR methods and can be optimized by adjusting the injection rate, pressure, and gas composition [1].

Gas Injection EOR Process

Gas injection is a typical EOR method for recovering light to medium oil from sandstone and carbonate reservoirs. Over the years, petroleum engineers have used this technique for reactivating old reservoirs. In addition to hydrocarbon gases such as propane and methane, nitrogen, flue gases, and carbon dioxide can also be used as injection fluids.

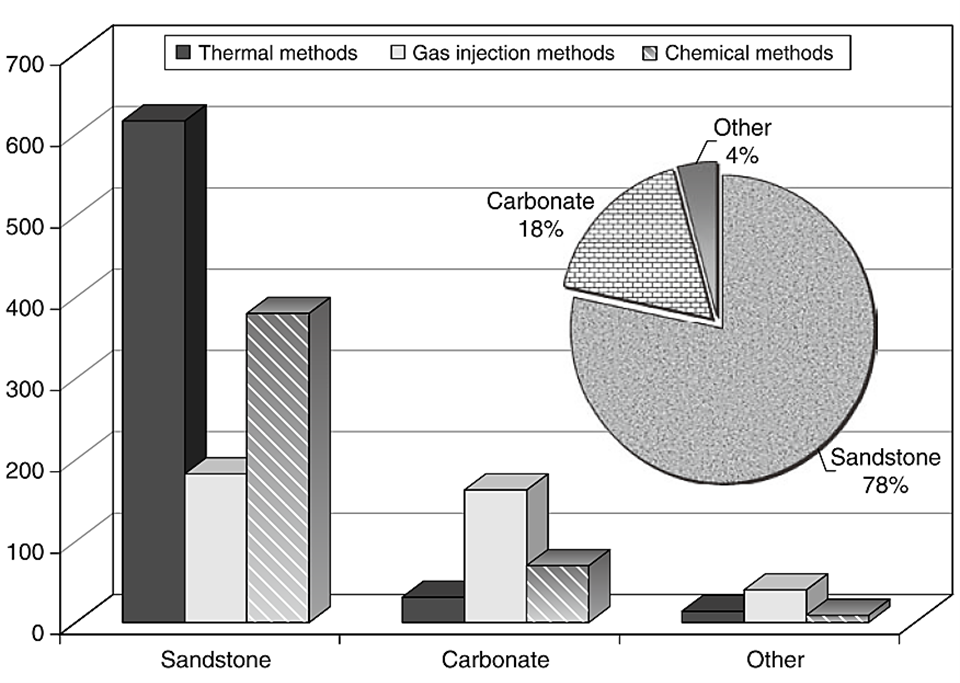

Figure 1 shows how the contribution of miscible or immiscible gas flooding in EOR projects has increased significantly. Hydrocarbon gases have long been used as injection fluids due to their easy availability and high recovery rates. However, the number of projects using hydrocarbon injection fluids has declined over the past two decades. This trend is due to the increasing demand for hydrocarbon gases in the residential and commercial sectors. In addition, more of these expensive gases are required because horizontal and vertical displacement is inefficient, making the process economically prohibitive. [2, 3].

Figure 1. Categorization of the global EOR processes [2]

Due to limitations in the use of hydrocarbon gases in enhanced oil recovery (EOR) operations, non-hydrocarbon gases have received considerable attention, with nitrogen and carbon dioxide being the primary option. Over 100 commercially operating nitrogen and carbon dioxide-based EOR projects are in the current market. Although non-hydrocarbon gases have relatively low oil recovery potential, their widespread use can be attributed to their cost-effectiveness and easy availability. The selection of non-hydrocarbon gases is governed by a comprehensive set of criteria detailed in the next section. [2, 4].

Screening Criteria for Selection of a Gas

Petroleum engineers evaluate various parameters when selecting an appropriate gas injection process for EOR. Nitrogen injection is a common gas injection technique used in EOR, particularly in high temperatures and pressure reservoirs. A screening criterion for the selection of an injection fluid is given as follows,

Table 1. Common screening criteria for an injection gas [5, 6]

| Gas type | Carbon dioxide | Nitrogen | Flue Gases |

| Properties | |||

| Oil Properties | |||

| Specific gravity (oAPI) | ~ 25 | 30 | 24 |

| Viscosity (Cp) | 13 | 9 – 11 | 9 – 11 |

| Reservoir Features | |||

| Oil Saturation | Around 30% of the PV | Around 30% of the PV | Around 30% of the PV |

| Formation Type | Carbonate or Sandstone | Carbonate or Sandstone | Carbonate or Sandstone |

| Depth (m) | More than 610 | Around 610 for LPG to 1525 for HP Gas | Around 610 for LPG to 1525 for HP Gas |

A comparison of the above reveals that nitrogen has the advantages of being nonflammable, chemically inert, and readily available. The use of nitrogen in EOR has been successful in several field projects worldwide [7]. When considering nitrogen injection, factors such as reservoir permeability, heterogeneity, and pressure must be evaluated to determine the optimal injection rate and pressure. The injection rate and pressure of nitrogen gas significantly impact oil recovery in low-permeability reservoirs.

Additionally, the effect of nitrogen injection on fluid properties, such as viscosity and interfacial tension, should be considered. Nitrogen injection can reduce oil viscosity, making displacing the oil easier and improving oil recovery. Using surfactants or polymers in conjunction with nitrogen injection can further enhance oil recovery by reducing interfacial tension and improving the sweep efficiency of the injected gas [8, 9].

Nitrogen Injection

Nitrogen gas injection is a well-established and effective EOR technique for light oil reservoirs that are characterized by high pressure and depth. The technique involves injecting nitrogen or flue gas into the reservoir, which vaporizes the lighter components of crude oil. This generates miscibility if the pressure is high enough, facilitating oil recovery by providing a gas drive in the reservoir. The use of nitrogen as an injection fluid was first reported in the 1960s in the United States, and since then, the technique has been further developed and optimized [10].

While most current projects involving nitrogen/flue gas injection are focused on sandstone reservoirs, there are also ongoing efforts to use this method in carbonate reservoirs (Alves et al., 2019). The success of the technique depends on several parameters, including fluid composition, displacement velocity, temperature, and the length of the tube’s column. Researchers have developed several correlations based on these parameters to predict the minimum miscibility pressure (MMP) for nitrogen/flue gas injection [11, 12].

A general correlation for oil with a specific gravity lower than 40 API was proposed as follows [5, 6, 13],

Where,

Whereas the correlation that can be used for oils having specific gravity above 40 API is given as follows,

Where,

= Molecular weight of fractions above C7

T = temperature in oF

Recent studies have focused on optimizing nitrogen/flue gas injection, exploring new injection strategies, and using alternative gases. For example, researchers have investigated using carbon dioxide as an injection gas, potentially enhancing oil recovery while mitigating greenhouse gas emissions. Additionally, there have been efforts to explore using nitrogen-assisted gravity drainage (NAGD) for heavy oil recovery [14, 15].

Oil Recovery from Carbonate Reservoirs

It is well known that most of the world’s oil reserves are located in carbonate reservoirs. However, these reservoirs have relatively low oil and gas recovery compared to sandstone reservoirs due to fewer lithologic pores and fractures. The recovery of hydrocarbon compounds from carbonate reservoirs has been the subject of extensive research, and various EOR techniques have been implemented to improve hydrocarbon recovery. These techniques include thermal recovery, chemical flooding, and gas injection. Among these, gas injection, including natural gas, carbon dioxide, and nitrogen, is the most commonly used EOR technique for carbonate reservoirs [16, 17].

Figure 2. An estimate of EOR methods in carbonate and sandstone reservoirs [3]

The low recovery of hydrocarbon compounds in carbonate reservoirs occurs due to their characteristics, such as low porosity and high heterogeneity, which cause fluids injected during enhanced recovery to bypass the oil in the rock matrix. As a result, it becomes challenging to recover oil from such reservoirs. Therefore, to enhance oil recovery, it is crucial to understand the reservoir’s geological and petrophysical properties thoroughly. The study of these properties can help select an appropriate EOR technique, optimize the injection parameters, and improve the overall recovery [18] [3].

Nitrogen Injection in Carbonate Reservoirs

Nitrogen-EOR methods are widely used to improve light oil recovery from carbonate reservoirs. Carbonate reservoirs have complex geological and petrophysical features, and their recovery is challenging due to their depth and pressure conditions. Nitrogen flooding is an effective EOR technique as it reduces the viscosity of the oil and enhances the reservoir pressure, leading to better oil recovery [2].

Nitrogen flooding can be carried out under miscible and immiscible conditions depending on the reservoir’s characteristics and desired outcomes [4]. Under immiscible conditions, nitrogen gas is injected into the reservoir to maintain pressure by filling the void spaces the extracted oil creates. Nitrogen gas can also be used to create drive for slugs of miscible fluid, resulting in better oil displacement. The immiscible process is suitable for reservoirs that have low oil saturation and high permeability, allowing for better sweep efficiency [3].

Several studies have investigated the effectiveness of nitrogen flooding for EOR in carbonate reservoirs. Thomas [4] compared the performance of various EOR techniques, including nitrogen flooding, for carbonate reservoirs. Likewise, Davarpanah, et al. [19] conducted a comparative simulation study of carbon dioxide and nitrogen flooding in carbonate reservoirs. Similarly, Alagorni, et al. [20] studied the effectiveness of nitrogen gas injection for EOR in sandstone and carbonate reservoirs [21]. The recovery of oil by using the injection of nitrogen is illustrated in the following figure,

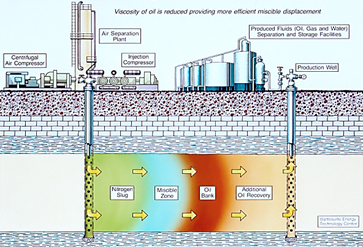

Figure 3. An illustration of oil recovery by the injection of nitrogen [22]

Case Study

In recent years, nitrogen gas injection has been applied in many Gulf oilfields to increase oil recovery by reducing the reservoir pressure and improving the displacement efficiency of the reservoir fluids. In this regard, a comprehensive study investigated three large onshore oilfields in Abu Dhabi. The reservoirs in Abu Dhabi are characterized by deep multi-layered non-clastic reservoirs. The study aimed to investigate the feasibility and effectiveness of nitrogen gas injection in these oilfields. The three reservoirs selected for the study were chosen based on their geological characteristics, reservoir properties, and production history.

To conduct this study, various techniques were employed, including core analysis, petrophysical analysis, and numerical simulation. The core analysis was carried out to determine the physical properties of the reservoir rock and to evaluate the reservoir’s permeability, porosity, and fluid saturations. The petrophysical analysis was conducted to estimate the reservoir’s initial fluid saturations and to analyze the well logs.

Finally, numerical simulation was performed to model the reservoir’s fluid flow and predict the reservoir’s behavior under nitrogen gas injection. The study showed that nitrogen gas injection could significantly improve oil recovery in the studied oilfields. The study also revealed that the success of nitrogen gas injection depends on several factors, including reservoir properties, injection rate, injection pressure, and the location of the injection wells. Therefore, carefully planning and designing the nitrogen gas injection process is crucial for achieving maximum benefits.

The minimum miscibility pressure (MMP) was also calculated for the multiple nitrogen-oil systems. The MMP value was defined as the minimum pressure required to mix the injected gas with the reservoir oil thoroughly. The experiments were carried out for multiple nitrogen-oil systems with varying compositions, reservoir temperatures, and pressures.

In the initial estimation of MMP, several correlations reported by earlier researchers were used. These were based on the properties of the reservoir fluid, such as molecular weight, critical temperature, and critical pressure. The results of the study showed that the calculated MMP values were consistent with the values predicted by the correlations used in the initial estimation. The study also revealed that the MMP values vary depending on the reservoir temperature, pressure, and composition of the nitrogen-oil system. Therefore, it is essential to conduct experiments to determine the actual MMP value for each reservoir. Sebastian and Hudgins’s correlations used in the study are given as follows,

PMMP = 5568 e-R1 + 3641 e-R1

R1 = 792 [C2-C5] / Mc7+ (T0.25)

R2 = 2.16*106 [C15.632] / Mc7+ (T0.25)

C1 = Mole fraction of methane in the oil reservoir

C2 – C5 = Mole fraction of ethane through pentanes

PMMP = 4603 ‐ 3283 * (CL*T/MW) + 4.776 * (CL2 *T2 /MW) ‐ 4.008 *

CI* T2 /MW) + 2.05*MW + 7.541 *T

CL = Mol fraction of methane in oil

CI = Mol fraction of intermediates (C2‐C6 & CO2) in oil

T = temperature of the reservoir in Rankine

MW = Mol weight of C7+ fraction in oil

The results suggested that nitrogen gas injection under miscible conditions can improve oil recovery in onshore oilfields with deep multi-layered non-clastic reservoirs. However, the success of the injection operation depends on various factors, including the reservoir conditions, the composition of the nitrogen-oil system, and the MMP value. Using correlations for the initial estimation of MMP can be helpful, but actual experiments are necessary to determine the MMP value for a particular reservoir.

The study’s empirical findings were also compared with the results of the numerical analysis. The numerical study was carried out using WINPROP with a CMG simulator. This enabled an easy investigation of various parameters. The simulation results gave a promising outlook for nitrogen injection under miscible conditions for all three reservoirs. Glaso and Hanssen’s correlations were too inaccurate to compare their values to the simulations. Whereas the Firoozabadi correlation showed no significant change in MMP values across the three reservoirs. However, Sebastian and Hudgins’s values proved reliable, as they varied between reservoirs and had low absolute deviations compared to the simulations (as seen in Table 5) [23].

Table 2. A comparison of the results obtained from correlations and simulation analysis [23]

| Field | MMP (Psia) | Absolute deviations from simulation (%) | ||||

| Sebastian | Hudgins | Firoozabadi | Simulated | Hudgins | Sebastian | |

| 1 | 5.94 × 104 | 5.95 × 104 | 6.45 × 104 | 5.93 × 104 | 0.45 | 0.92 |

| 2 | 3.65 × 104 | 3.01 × 104 | 6.46 × 104 | 3.71 × 104 | 20 | 2 |

| 3 | 4.52 × 104 | 5.19 × 104 | 6.47 × 104 | 5.42 × 104 | 4 | 15 |

Advantages and Disadvantages of Nitrogen-EOR

Hydrocarbon injection has been used for enhanced oil recovery (EOR) for over 50 years. It has played a crucial role in the completion and workover of oil wells. However, due to safety concerns such as flammability and potential explosion hazards, the use of hydrocarbon-EOR is not in practice these days. In contrast, nitrogen-EOR has gained popularity due to its non-flammable and non-corrosive properties. Nitrogen gas can also be produced on-site through extraction from the air, making it cost-effective. Despite these benefits, the widespread use of nitrogen-EOR is hindered by some major limitations. The high capital investment required for the separation and operational equipment for nitrogen injection limits its potential applications.

The costs associated with nitrogen-EOR may not be feasible for smaller oilfields with lower production rates, where nitrogen injection’s capital and operational costs could outweigh the benefits. However, as technology advances and costs decrease, nitrogen-EOR may become a more viable option for oilfield development. Advances in separation equipment and operational techniques may also reduce the overall costs associated with nitrogen injection. As such, nitrogen-EOR has the potential to play an important role in improving oil recovery in the future [13, 24].

Comparison of Nitrogen with other gases for EOR

Relative permeability is a fundamental reservoir property crucial in evaluating and assessing its performance. It is defined as the ratio of the fluid’s effective permeability to the reservoir rock’s total permeability. In gas injection EOR processes, the effects of injection gases on the relative permeability must be carefully determined. This is because a reservoir’s relative permeability can affect oil production, internal pressure, and overall recovery efficiency [25].

A recent study by Ghoodjani and Bolouri [26] investigated the effects of nitrogen injection on relative permeability and reservoir parameters. These investigations were also carried out using carbon dioxide injection for comparison. The study utilized rock samples sourced from a typical carbonate reservoir. The samples were injected with light oil sourced from the Naftshahr oil field. This approach led to creating of a small carbonate reservoir, allowing for evaluating gas injection EOR using a core flood apparatus.

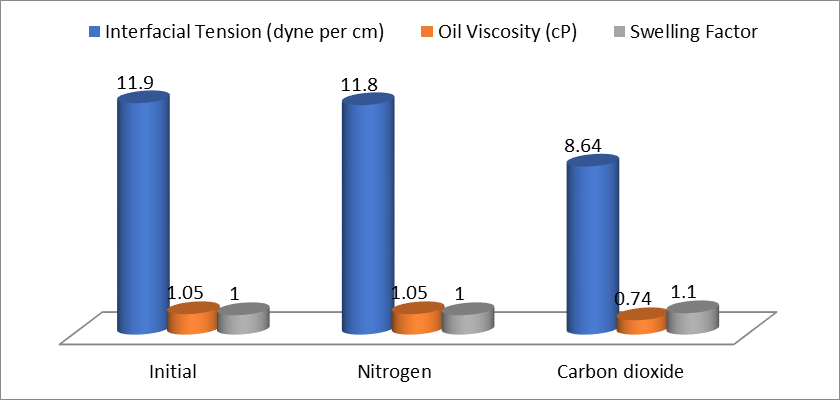

The study’s findings indicated that carbon dioxide injection had a more significant impact on relative permeability than nitrogen injection. This was attributed to the carbon dioxide’s higher oil solubility and ability to reduce oil viscosity, enhancing oil flow through the reservoir. The study also found that adding surfactants further improved the effectiveness of gas injection EOR. The experimental findings indicate that nitrogen exhibits a low degree of solubility in oil, thereby exerting minimal influence on the properties of both oil and rock. In contrast, significant effects of carbon dioxide were observed concerning oil viscosity, interfacial tension, and oil swelling. The findings are visually represented in the following figure,

Figure 4. Comparison of nitrogen and carbon dioxide on miscellaneous characteristics of oil

Various studies have demonstrated a strong correlation between relative permeability and interfacial tension. Interfacial tension is defined as the energy required to create a unit area of interface between two immiscible fluids. The relationship between interfacial tension and relative permeability can be described using the expressions for interfacial tension as discussed in the literature [26]. For instance, research by Zhang and Jin [27] investigated the impact of interfacial tension on relative permeability during gas injection EOR. The study found that interfacial tension significantly influenced the reservoir’s relative permeability. Similarly, other studies by Sheng [28], Abbas, et al. [29], and Samala, et al. [30] also highlighted the importance of considering interfacial tension when determining the relative permeability of a reservoir.

Given that the raw material is made from air, the only factor that can affect where a liquid nitrogen manufacturing facility is located is power availability. Gases, including liquid oxygen and other rare gases, are also produced during liquid nitrogen production. Rail cars are used to transport liquid nitrogen from these plants to end users or bigger suppliers. In normal practice, vacuum-jacketed cryogenic tanks are used for transport via rail cars and trucks. These are often provided with an inner tank of stainless steel to hold the liquid nitrogen and an outer shell of mild steel that creates a vacuum to serve as insulation. These tanks are equipped with pressure-release valves to let nitrogen gas out as pressure builds up inside the tank as a result of heat-induced gas expansion. Liquid nitrogen can be transported in rail cars with a 1,200,000 SCF capacity, but only 7,000 gallons can be stored in commercial truck tanks.

Nanotechnology in Nitrogen-EOR

In recent years, fluid foams have been used to extract oil from tight reservoirs by avoiding channelling and fingering. In this regard, nanoparticles have partially replaced surfactants in modern gas-foam injection techniques. To stabilize foam in challenging reservoir conditions, extensive research has been done on generating strong adsorption at the interface. Silicon dioxide (SiO2) is a natural substance typically considered an environmentally friendly additive. Its nanoparticles have recently been the focus of foam stabilization research. Untreated SiO2 nanoparticles are hydrophilic and can penetrate liquid films. This leads to the formation of a double layer of tightly packed particles that act as a network and a single layer of bridging particles. Recent studies using nonionic surfactants examined the foam-stabilizing abilities of various SiO2 nanoparticles. Due to their greater diffusivity and higher interface, the researchers found that smaller nanoparticles produce more stable foam. However, one drawback of SiO2 nanoparticles is that they have a negative surface charge, which makes it challenging to control hydrophobicity [31-33].

Numerous researchers have examined how anionic surfactants and surface-modified SiO2 nanoparticles stabilize foams. In a study [34], hydrophobic SiO2 nanoparticles modified at the surface were used to investigate the synergistic mechanism of foam stabilization with surfactants and the rheological characteristics of the gas-liquid interface. The researchers noticed that a particular concentration of surfactant molecules was adsorbed onto the surfaces of the nanoparticles. This led to an increase in the surface activity of the particles. The structure of the particle’s interface layer was altered, enabling the particles to adsorb at the gas-liquid interface. As a result, the foam’s stability and expansion viscoelastic modulus were improved.

In this regard, another study showed that using hydrophobic SiO2 nanoparticles modified at the surface can enhance the foam stabilization properties of anionic surfactants. Increased surface activity in the surface-modified nanoparticles made adsorbing at the gas-liquid interface easier. It was also found that the structure of the particle-particle interface layer was subsequently altered. This led to an enhancement in the foam’s stability and expansion viscoelastic modulus. Future research might be needed to optimize surfactant and nanoparticle concentration to achieve the most effective stabilization of foams [35].

Numerous studies have looked into using foam stabilized with nanoparticles for various applications. The gas source must be carefully chosen and used to implement foam technology successfully. In China, nitrogen separation technology is much developed; therefore, nitrogen foam flooding continues to be the primary method for oil recovery. Although air foam is practical, its high oxygen content frequently causes downhole tubular strings to rust. This issue makes it an undesirable option for some applications. On the other hand, carbon dioxide foam flooding has shown excellent oil displacement effects in oil fields—however, the lack of carbon dioxide gas sources and their high-cost limit its application in some places.

Future studies can examine different gas sources and their potential uses in nanoparticle-stabilized foam. To choose the best gas source for the efficient and long-lasting use of nanoparticle-stabilized foam technology, it is also crucial to consider the unique requirements and constraints of various applications and environments [36, 37].

Conclusion

The nonhydrocarbon gas injection has tremendous potential for retrieving oil from mature reserves through miscible or immiscible displacement methods. The analysis of recently published material shows that more than ten ventures have been established on miscible nitrogen injection, with most operating under the immiscible regime to retain reservoir pressure. Carbonate reservoirs are one of the most abundant oil and gas reservoirs globally. One of the key challenges in extracting oil from these reservoirs is their low permeability. Various gases, such as carbon dioxide, nitrogen, and hydrogen sulfide, have been studied for their potential in EOR in carbonate reservoirs. Comparing these gases has revealed that each gas has its advantages and limitations. Nitrogen is a relatively inert gas that can be injected easily into the reservoir. However, its low solubility in oil and its tendency to bypass the oil can limit its effectiveness in EOR. Nitrogen injection has been combined with other EOR methods, such as surfactants or alkali flooding, to overcome these limitations. Injecting nanoparticles into oil reservoirs is one of the most promising and modern uses of nanotechnology in EOR. With less interfacial tension, oil can flow through the reservoir and be extracted more. Additionally, nanoparticles can block rock pores to increase oil flow while decreasing water flow.

References

[1] L. Romero-Zerón, Advances in Enhanced Oil Recovery Processes. INTECH Open Access Publisher, 2012.

[2] A. Al Adasani and B. Bai, “Analysis of EOR projects and updated screening criteria,” Journal of Petroleum Science and Engineering, vol. 79, no. 1, pp. 10-24, 2011.

[3] A. Vladimir and M. Eduardo, Enhanced Oil Recovery: Field Planning and Development Strategies. Burlington: Gulf Professional Publishing, 2010.

[4] S. Thomas, “Enhanced oil recovery-an overview,” Oil & Gas Science and Technology-Revue de l’IFP, vol. 63, no. 1, pp. 9-19, 2008.

[5] W. C. Lyons and G. J. Plisga, Standard handbook of petroleum and natural gas engineering. Gulf Professional Publishing, 2011.

[6] T. Ahmed, “Minimum miscibility pressure from EOS,” presented at the Canadian International Petroleum Conference, 2000.

[7] S. A. Farzaneh and M. Sohrabi, “A review of the status of foam applications in enhanced oil recovery,” in EAGE Annual Conference & Exhibition incorporating SPE Europec, 2013: OnePetro.

[8] R. Liu, H. Liu, X. Li, and Z. Fan, “The reservoir suitability studies of nitrogen foam flooding in Shengli Oilfield,” in SPE Asia Pacific oil and gas conference and exhibition, 2008: OnePetro.

[9] K. Ma, X. Jia, J. Yang, Y. Liu, and Z. Liu, “Nitrogen foam flooding test for controlling water cut and enhance oil recovery in conventional oil reservoirs of China offshore oilfield,” in SPE Asia Pacific oil and gas conference and exhibition, 2013: OnePetro.

[10] B. D. Al-Anazi, “Enhanced oil recovery techniques and nitrogen injection,” CSEG recorder, vol. 32, no. 8, pp. 29-33, 2007.

[11] E. Manrique, M. Gurfinkel, and V. Muci, “Enhanced oil recovery field experiences in carbonate reservoirs in the United States,” in Proceedings of the 25th Annual Workshop & Symposium Collaborative Project on Enhanced Oil Recovery, International Energy Agency, 2004, vol. 111, pp. 667-686.

[12] O. Glaso, “Generalized pressure-volume-temperature correlations,” Journal of Petroleum Technology, vol. 32, no. 05, pp. 785-795, 1980.

[13] E. Manrique, M. Gurfinkel, and V. Muci, “Enhanced oil recovery field experiences in carbonate reservoirs in the United States,” 2004.

[14] P. L. Pavlova, A. V. Minakov, D. V. Platonov, V. A. Zhigarev, and D. V. Guzei, “Supercritical fluid application in the oil and gas industry: a comprehensive review,” Sustainability, vol. 14, no. 2, p. 698, 2022.

[15] L. Tao et al., “Experimental study on nitrogen and nitrogen foam-assisted gravity drainage for enhancing oil recovery,” Journal of Petroleum Exploration and Production Technology, vol. 9, pp. 2625-2634, 2019.

[16] C. H. Moore and W. J. Wade, Carbonate reservoirs: Porosity and diagenesis in a sequence stratigraphic framework. Newnes, 2013.

[17] J. J. Sheng, Enhanced Oil Recovery Field Case Studies: Chapter 5. Surfactant–Polymer Flooding. Elsevier Inc. Chapters, 2013.

[18] J. Borgomano, J.-P. Masse, and S. Al Maskiry, “The lower Aptian Shuaiba carbonate outcrops in Jebel Akhdar, northern Oman: Impact on static modeling for Shuaiba petroleum reservoirs,” AAPG bulletin, vol. 86, no. 9, pp. 1513-1529, 2002.

[19] A. Davarpanah, B. Mirshekari, and A. A. Razmjoo, “A simulation study of water injection and gas injectivity scenarios in a fractured carbonate reservoir: A comparative study,” Petroleum Research, vol. 4, no. 3, pp. 250-256, 2019.

[20] A. H. Alagorni, Z. B. Yaacob, and A. H. Nour, “An overview of oil production stages: enhanced oil recovery techniques and nitrogen injection,” International Journal of Environmental Science and Development, vol. 6, no. 9, p. 693, 2015.

[21] V. Alvarado and E. Manrique, “Enhanced oil recovery: an update review,” Energies, vol. 3, no. 9, pp. 1529-1575, 2010.

[22] NETL. “Nitrogen Flooding ” National Energy Technology Laboratory. http://www.netl.doe.gov/kmd/cds/disk22/A-Introduction/colnf.pdf (accessed 3rd August 2015).

[23] H. Belhaj, A. Khalifeh, H. Abu, and K. Javid, “Potential of Nitrogen Gas Miscible Injection in South East Assets, Abu Dhabi,” in North Africa Technical Conference and Exhibition, 2013: Society of Petroleum Engineers.

[24] S. Siregar et al., “Laboratory experiments on enhanced oil recovery with nitrogen injection,” Journal of Engineering and Technological Sciences, vol. 39, no. 1, pp. 20-27, 2007.

[25] B. Pan et al., “Impacts of relative permeability hysteresis, wettability, and injection/withdrawal schemes on underground hydrogen storage in saline aquifers,” Fuel, vol. 333, p. 126516, 2023.

[26] E. Ghoodjani and S. Bolouri, “Experimental study of CO2-EOR and N2-EOR with focus on relative permeability effect,” J Pet Environ Biotechnol, vol. 2, no. 10, p. 6, 2011.

[27] M. Zhang and Z. Jin, “Molecular simulation on CO2 adsorption in partially water-saturated kaolinite nanopores in relation to carbon geological sequestration,” Chemical Engineering Journal, vol. 450, p. 138002, 2022.

[28] J. J. Sheng, “Status of surfactant EOR technology,” Petroleum, vol. 1, no. 2, pp. 97-105, 2015.

[29] A. H. Abbas, W. R. W. Sulaiman, M. Z. Jaafar, A. O. Gbadamosi, S. S. Ebrahimi, and A. Elrufai, “Numerical study for continuous surfactant flooding considering adsorption in heterogeneous reservoir,” Journal of King Saud University-Engineering Sciences, vol. 32, no. 1, pp. 91-99, 2020.

[30] R. Samala, A. Chaudhuri, R. Vishnudas, J. Yeswanth, and V. Selvam, “Numerical analysis of viscous fingering and oil recovery by surfactant and polymer flooding in five-spot setup for water and oil-wet reservoirs,” Geomechanics and Geophysics for Geo-Energy and Geo-Resources, vol. 6, pp. 1-18, 2020.

[31] Q. Sun et al., “Aqueous foam stabilized by partially hydrophobic nanoparticles in the presence of surfactant,” Colloids and Surfaces A: Physicochemical and Engineering Aspects, vol. 471, pp. 54-64, 2015.

[32] I. Kim, A. J. Worthen, K. P. Johnston, D. A. DiCarlo, and C. Huh, “Size-dependent properties of silica nanoparticles for Pickering stabilization of emulsions and foams,” Journal of Nanoparticle Research, vol. 18, pp. 1-12, 2016.

[33] A. J. Worthen, H. G. Bagaria, Y. Chen, S. L. Bryant, C. Huh, and K. P. Johnston, “Nanoparticle-stabilized carbon dioxide-in-water foams with fine texture,” Journal of colloid and interface science, vol. 391, pp. 142-151, 2013.

[34] Q. Sun, Z. Li, S. Li, L. Jiang, J. Wang, and P. Wang, “Utilization of surfactant-stabilized foam for enhanced oil recovery by adding nanoparticles,” Energy & Fuels, vol. 28, no. 4, pp. 2384-2394, 2014.

[35] Z. AlYousef, M. Almobarky, and D. Schechter, “Enhancing the stability of foam by the use of nanoparticles,” Energy & Fuels, vol. 31, no. 10, pp. 10620-10627, 2017.

[36] A. Ocampo et al., “Successful foam EOR pilot in a mature volatile oil reservoir under miscible gas injection,” in International Petroleum Technology Conference, 2013: OnePetro.

[37] Y. Hurtado et al., “Effects of surface acidity and polarity of SiO2 nanoparticles on the foam stabilization applied to natural gas flooding in tight gas-condensate reservoirs,” Energy & fuels, vol. 32, no. 5, pp. 5824-5833, 2018.

To all knowledge

To all knowledge