Multi-product pipelines transport different hydrocarbon liquid products in batches in a single pipeline, such as Diesel, Petrol, Kerosene, and Jet Fuel.

Since the products transported in the pipelines are potentially hazardous to the environment and people in areas surrounding the pipeline, sound engineering standards and practices should be followed.

These design standards and considerations are crucial when designing, installing, and operating a multi-product pipeline. EPCM discusses below

1 Multi-Product Pipelines: ASME B31.4

The American Society of Mechanical Engineers (ASME) B31 committee was originally established in 1926. The committee then introduced the ASME B31 code, which dates back to 1935. The American Society of Mechanical Engineers developed and published the code, which they maintain. The ASME B31 Code governs the rules and regulations for Pressure Piping systems. The code has been divided into different sections throughout the years, each governing a respective pressure piping system. Some sections have been folded into others, while other standards have superseded others.

The ASME B31 code is currently divided into the following sections:

- Power Piping, ASME B31.1,

- Process Piping, ASME B31.3,

- Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids, ASME B31.4,

- Refrigeration Piping and Heat Transfer Components, ASME B31.5,

- Gas Transmission and Distribution Piping Systems, ASME B31.8,

- Building Services Piping, ASME B31.9, and

- Hydrogen Piping and Pipelines, ASME B31.12.

The ASME B31.4 code contains important factors that must be considered. The latest published version is 2016, and the next edition is scheduled for publication in 2019. The 2019 version will take effect six months after the date of issuance.

1.1 Background – ASME Code B31 – Section B31.4

This section of the B31 code covers all minimum requirements for the most important factors of a pipeline transportation system, namely design, materials, components, fabrication, testing, inspection, operation, and maintenance. Transportation pipelines include all piping systems between the production fields or facilities, including above or below-ground storage facilities, refineries, processing facilities, pump stations, terminals, and tank farms. Section B31.4 also covers the pipelines transporting slurries of non-hazardous materials.

- This section also includes primary/associated auxiliary liquid petroleum and liquid anhydrous ammonia piping at pipeline terminals (marine, rail, and truck), tank farms, pump stations, pressure-reducing stations, metering stations, scraper traps, strainers, and prover loops.

- Storage tanks, working tanks, pipe-type storage (fabricated from pipe and fittings), and piping interconnecting these facilities.

- Liquid petroleum and liquid anhydrous ammonia piping located on property that has been set aside for such piping within petroleum refineries, natural gasoline, gas processing, ammonia, and bulk plants.

- Aspects of the operation and maintenance of liquid pipeline systems relating to the safety and protection of the general public, operating company personnel, environment, property, and piping systems.

The piping systems above consist of pipe, flanges, bolting, gaskets, valves, relief devices, fittings, and pressure-containing parts of other piping components. All materials must conform to specifications listed in tables as described in the ASME B31.4 code.

If the material is not listed in the tables mentioned above, it must meet the requirements of the ASME B31.4 code for non-listed materials. This code also includes hangers, supports, and other equipment necessary to prevent overstressing the pressure-containing parts. It does not include support structures such as building frames or foundations.

Careful application of the ASME B31.4 standard will help pipeline industry users comply with applicable regulations within their jurisdictions while achieving the operational, cost, and safety benefits of the many industry best practices detailed in this volume.

2 Multi-Product Pipelines: Designing A Pipeline

When designing a pipeline transportation system, a certain process is followed upon selecting the applicable code, in this case, ASME B31.4. This section will discuss the typical process followed.

2.1 Routing

2.1.1 Preliminary Planning

During the routing phase of the pipeline, a preliminary planning process is followed and can be broken down into a few common aspects. The following aspects will normally be determined during the planning phase: the origin and the end destination of the pipeline, the product to be transported, the hydraulic factors such as the pipe diameter, and the type of flows expected in the pipeline. The approximate capital cost and running expenses will also be considered during the pre-planning phase, although they do not pertain directly to the technical design of the pipeline.

2.1.2 Route Selection

Pipeline route selection can be done on various platforms. It can typically be selected on a highway map, topographical map, or Google platforms such as Google Earth. It is good practice to obtain the most recent aerial photography to gather the required data for route maps and property plans. This data will be required for right-of-way acquisition.

2.1.3 Right of Way Acquisition

A thorough assessment of the proposed right-of-way and its surrounding natural environment is done to identify the unique features that must be protected throughout the life of the pipeline. It is quite a rigorous process to obtain the right of way for a pipeline, and various considerations must be considered. The following subsections will explain some of the important considerations in more detail.

2.1.3.1 Environment

Analyzing environmentally sensitive areas that need to be avoided and having environmental experts complete an assessment on the entire proposed pipeline route is known as an Environmental Impact Assessment; an abbreviation typically used in industry is EIA.

2.1.3.2 Landowners

Determining who owns the land and what it is currently used for. The pipeline owners will typically engage with landowners to negotiate a sale or lease agreement to obtain the land on the proposed right of way.

2.1.3.3 Infrastructure

Mapping third-party infrastructure, such as structures, power lines, roads, and railways. The proposed right of way may influence the infrastructure.

2.1.3.4 Stakeholders

Working with local communities to understand their needs, concerns and plans.

2.1.3.5 Geography

Avoiding geohazards such as steep slopes, landslides and seismic faults. Elevation profiles are another important aspect that one has to take into consideration.

2.1.3.6 Road Access

Determining how construction and maintenance teams will access the area where the pipeline is buried after construction.

2.1.3.7 Local Communities

Identifying treaty lands, reserves or traditional land use.

2.1.3.8 Emergency Response

Determining the most efficient access for emergency crews and their equipment.

2.1.3.9 Climate

Studying seasonal variations in temperature and weather.

A pipeline’s final rig pipeline will only be decided upon once all the above considerations have been investigated and all problems have been resolved. The route where the pipeline is buried after construction will now be known as the pipeline right-of-way.

2.2 Pipeline Hydraulics and Line Sizing

During the pipeline hydraulic phase, the designer determines the head losses expected in the pipeline transportation system. Secondly, the designer will determine the pressures required in the pipeline to achieve an adequate flow to transport the fluid from start to end. The designer will make various assumptions to complete the hydraulic calculations. The assumptions will include selecting a pipeline size before conducting the calculations. This can be an iterative process until the calculations indicate an adequate size. A typical pipeline hydraulic calculation process will be summarized in this section.

2.2.1 Pressure Drop Equation

Considering the ASME B31.4 code, which is relevant for liquid petroleum transportation systems, the following assumption has to be made at the start of the process. It has to be assumed that the Fluid under consideration is incompressible and single phase.

The Pressure drop (ΔP) in the pipe is then calculated using the Darcy – Weisbach equation:

Where f is the Darcy friction factor, L is the length of the pipe, D is the pipeline’s inner diameter, v is the fluid velocity, and ρ is the fluid density

2.2.2 Darcy Friction Factor

The Friction factor is a function of the fluid’s Reynolds’s calculated as follows:

where μ is fluid viscosity and D (Diameter), V (Velocity), and ρ (Density) are as derived above.

For Re < 2100, the flow is said to be laminar, and the friction factor is calculated as follows:

For Re > 4000, the flow is said to be turbulent, and the friction factor is obtained by solving the Colebrook-White equation.

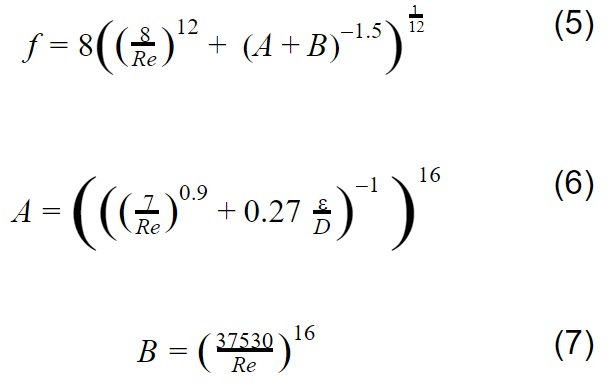

where ε is pipe roughness based on the pipe’s material (assumed at this stage); note that the Colebrook equation is an iterative process, and 20 iterations are typically performed; this is at the designer’s discretiodesigner’s0 < Re < 4000, the flow is in the critical zone or transition range between laminar and turbulent flow, with no definite friction factor. The Churchill equation predicts a friction factor for the entire flow regime from laminar to turbulent; it is used to get an estimate of the friction factor in the critical zone.

Note that all temperature-dependent properties (density and viscosity) are assumed constant and will be taken at 15ºC for this example.

2.2.3 Fluid Properties

During the hydraulic phase, the certain fluid properties in question need to be taken into consideration, for example:

- Diesel

- Naphtha

The designer will then list the applicable properties of the fluids in question; Table 1 below illustrates an example of such properties.

Table 1: Naphtha and Diesel Properties

| Product | Density (kg/m3) | Dynamic Viscosity (cP) |

| Diesel | 820 – 890 | 3.1 – 3.5 |

| Naphtha | 640 – 830 | 1 – 1.2 |

2.2.4 Hydraulic Analysis

Typical assumptions used during a hydraulic analysis are listed below. The assumptions are typically project-specific and are chosen at the designer’s discretiodesigner’s cases; the client will state desired flow rates and pipe sizes; the designer will then run the calculations to confirm whether the client’s expectations are realistic and provide feedback.

- Pipeline size: 18”

- Pipe wall thickness”: 9.53mm

- The flow rate of product: 1000 m3/hr

- The distance of Pipe: 6km

- Pipe roughness: 0.046 mm

- Oil Tanker discharge pressure: 10 barg

- Maximum allowable pressure drop over the 6km: 8 bar (pipeline) and 2 bar Tank head

- Maximum allowable velocity in the pipe: 4 m/s

- Velocity at 1000m3/hr: 1.844 m/s

- Assumed change in pipeline elevation: 6m

Table 2 shows the results of the calculations performed using the above equations and assumptions during the hydraulic calculations phase.

Table 2: Hydraulic Analysis

| Product | Density (kg/m3) | Dynamic Viscosity (cP) | Pipeline Pressure Drop (bar) | Tank Head Pressure (bar) | Total Pressure drop (bar) | Maximum flow @ ΔP = 10bar (m3/hr) | Velocity at max flow (m/s) |

| Crude Oil | 870 | 27 | 5.51 | 1.71 | 7.22 | 1200 | 2.2 |

| Diesel | 890 | 3.5 | 3.94 | 1.75 | 5.69 | 1500 | 2.8 |

| Naphtha | 830 | 1.2 | 3.27 | 1.63 | 4.9 | 1700 | 3.14 |

The designer will then conclude and make recommendations based on the results obtained. Based on the above scenario, a typical observation is that the flow rate of 1000 m3/hr is adequate for the operation of all three products.

2.3 Material Selection

Once design conditions are established, piping can be specified. The first item to determine is what material to use. Different materials have different temperature limitations. Chapter III, section 423 in ASME B31.4 provides additional limitations for various pipeline materials. Material selection is also dependent on the system fluid, such as the use of nickel alloy for a corrosive chemical pipeline application, the use of stainless steel to convey clean instrument air or the use of carbon steel with high chromium content (greater than 0.1%) to prevent flow accelerated corrosion. Carbon steel material is the most commonly selected material for pipeline transportation systems. Flow accelerated corrosion (FAC) is an erosion/corrosion phenomenon that has been demonstrated to cause severe wall thinning and pipe failure in some of the most critical piping systems.

The following two tables summarise the applicable material specifications and standards extracted from the ASME B31.4 code.

Figure 1, Material Standards Table Extracted from ASME B31.4

Figure 2, Material Standards Table Extracted from ASME B31.4

2.4 Wall Thickness and Stress Calculations

Variables in these equations include maximum allowable stress, pipe outside diameter, material coefficient and any additional thickness allowance (as described below). With so many variables involved, specifying a proper piping material, nominal diameter, and wall thickness can be an iterative process that may incorporate fluid velocity, pressure drop, and pipe and pumping cost. Whatever the application, the minimum required wall thickness must be verified.

Additional thickness allowances may be added to compensate for several reasons, including FAC. An allowance may also be required to provide additional strength to prevent damage, collapse, excessive sag, or pipe buckling due to superimposed loads. Finally, an allowance may be added to compensate for corrosion and/or erosion. The thickness of this allowance is, in the designer’s judgment, consistent with the expected life of the piping.

The minimum pipe wall thickness, or schedule, may not be constant over a range of pipe diameters and may require the specification of different schedules for different diameters. Corresponding schedule and wall thickness values are defined in ASME B36.10 Welded and Seamless Wrought Steel Pipe.

When specifying pipeline material and performing the above calculations, ensuring that the maximum allowable stress values used in calculations match the specified material is important. For example, if API 5L Grade B pipe were mistakenly specified instead of API 5L X42 pipe, the wall thickness provided could be insufficient due to the difference in maximum allowable stress values between the two materials. Similarly, the pipe manufacturing method should also be specified properly. For example, if calculations are performed using maximum allowable stress values for seamless pipe, then seamless pipe should be specified. If not, the seam-welded pipe may be provided by the fabricator/erector, which could result in insufficient wall thickness due to a lower maximum allowable stress value.

As an example, assume piping is sized for the following operating conditions, material, and product properties, summarized and used in the example calculations to follow:

| Operating Conditions | |

|

50 °C |

|

15 °C |

|

20 Bar = 2 MPa |

|

15 Bar |

The material to be used for the pipeline example is API 5L PSL 1 Grade B or X42, which is either seamless or electric resistance welded (ERW). The mechanical properties of the pipeline material, except where otherwise stated, and the table referenced throughout this example can be located in the ASME B 31.4 code.

| API 5L PSL 1 Steel: | Grade B | X 42 |

|

241 MPa | 289 MPa |

|

174 MPa | 208 MPa |

The Maximum Allowable Stress is calculated by using the following calculation as stated in the code:

The following properties account for both Grade B and X 42 steel:

|

8-inch (200 mm)6-inch (150 mm) |

|

8-inch pipe, 8.2 mm6-inch pipe, 7.1 mm |

|

7,850 kg/m3 |

2.4.1 Wall Thickness Calculations

This section discusses the calculations required to establish wall thickness and allowable stresses. The equations used to calculate these are extracted from the ASME B 31.4 code.

The minimum pipe wall thickness is calculated by first calculating the thickness required for the pressure flow and then adding to corrosion allowances. The corrosion allowance is specified as 0.5 mm/pa for 30 years by DIN 50929-3, table 8. The corrosion allowance used for this example is 1.5 mm to increase life expectancy.

The wall thickness is calculated as follows:

Calculated for 8-inch pipe

Calculated for 6-inch pipe

Thus, the pipeline wall thickness of 8.2 mm, as specified by the API 5L spec, is more than adequate for the design pressure of 20 Bar.

2.4.2 Stress Calculations

The stresses that are induced on the pipe wall due to counteracting forces against internal pressure and thermal expansion are known as Longitudinal Stresses.

Calculated for 8-inch pipe

Calculated for 6-inch pipe

|

200 GPa |

|

6.5 × 10-6 |

|

0.3 |

It is thus necessary to equate the Hoop Stress first.

Calculated for 8-inch pipe

Calculated for 6-inch pipe

subsequently,

The allowable stress within the pipe is governed by the Maximum Shear Stress Theory of Failure as outlined in ASME B31.4. According to this theory, the equivalent tensile stress must not exceed 90% of the pipe’s specified yield strength (Sy). The results confirm that the the 8-inch- and 6-inch pipe design complies with the Maximum Shear Stress Theory of Failure.

The above calculations were done for Grade B steel, which has a lower allowable stress value than X42 steel. Therefore, X42 steel will also be adequate.

2.4.3 Valves, Fittings and Equipment

Generally, all valves, fittings, and other pressure-containing components manufactured following the standards listed in ASME B31.4 shall be considered suitable for use under normal operating conditions.

To simplify the design, the designer may choose to set design conditions conservatively high to meet the flange ratings of a certain pressure class (e.g., ASME Class 150, 300, etc.) defined by the pressure-temperature ratings for a particular material specified in ASME B16.5 Pipe Flanges and Flanged Fittings or a similar standard listed in Figures 1 and 2 contained in section 3.3 of this article, Material selection. This is acceptable, provided it does not cause an unnecessary increase in wall thickness or other component design.

All equipment needs to be selected according to relevant pressure and fitting requirements. Pump sets, for example, are part of the pipeline transportation system.

2.5 Dimensional Requirements

This section of the code describes all standard and non-standard piping components. All piping components must adhere to certain dimensions to make pipeline construction uniform. When flanged or threaded valves are considered, it must be noted that these components are all governed by the ASME B16.34 specification (this is only one example of dimensional requirements). This specification allows valve manufacturers to conform to certain dimensions; this is considered when designing and constructing pipeline transportation systems that allow uniformity throughout the system. Dimensional standards are stipulated in the extract from the ASME B31.4 code below.

Figure 3, Table SummarizSummarizingl Dimensional Specifications

2.6 Construction, Welding and Assembly

This section stipulates that new construction and any changes or upgrades to existing pipeline transportation systems shall follow the requirements set out in the code. This includes handling pipe, welding, equipment, materials, and all the construction factors contributing to safety and sound engineering practice.

Detailed welding methods, procedures, and welder qualifications are stipulated in this section. The methods and procedures describe the number of weld passes required on certain wall thicknesses. The acceptable butt-welded joint design section for equal and unequal wall thicknesses gives the user an indication of how to bevel pipe ends to ensure adequate weld penetration. Safely crossing railroads or highways when constructing a pipeline is also described. The method to be followed when this obstacle has to be overcome is also detailed. The above summation is brief, and it should be noted that all other requirements of this section are described in detail in the ASME B31.4 code.

Figure 4 Acceptable Butt-Welded Joint Design for Unequal Wall Thicknesses

Figure 6 Acceptable Butt-Welded Joint Design for Equal Wall Thicknesses

2.7 Inspection and Testing

A pipeline inspector has to have the correct qualifications when inspecting a pipeline installation; this section stipulates all requirements a quality inspector should adhere to. The pipeline installation should comply with the relevant material specifications, construction methods, and testing requirements stipulated in the ASME B31.4 code. The correct testing procedures are prescribed in this section, ex. the correct method to perform a hydro-pressure test, and the parameters that need to be considered during this test. Various applicable non-destructive evaluations (NDEs) and their implementation are prescribed to ensure full pipeline integrity.

2.8 Operation and Maintenance Procedures

The codes state that it is difficult to prescribe specific operation and maintenance procedures covering all pipeline transportation systems cases. However, each operating company can tailor its procedures based on the provisions of the ASME B31.4 code. Site-specific operations and maintenance procedures should always employ all relevant safety considerations.

2.9 Remaining Chapters of ASME B31.4 Code

It should be noted that the remaining chapters of the code will not be discussed in this article, though they should be referred to if necessary. The remaining chapters are:

- Corrosion Control

- Offshore Liquid Pipeline Systems

- Carbon Dioxide Pipeline Systems

- Slurry Pipeline Systems

3 Multi-Product Pipelines: Crossing

3.1 Introduction

During the route construction of a pipeline, crossing certain roads, railways and/or certain natural occurrences like rivers or other types of water mass is often required. The main types of crossings generally include the following:

- Third-Party Services

- Roads and Railways

- Rivers

- Other Forms of Water Mass

These crossings can be achieved through several methods. A detailed breakdown of the various types of crossing methods is discussed below.

3.2 Open Cut Crossings

Open-cut methods can achieve most minor water, road, and railway crossings. These techniques entail the use of trenching technology. During open-cut crossing establishments for a road, the trench is excavated across the road; therefore, this application is mostly used for small, single-track roads. The road will usually be closed temporarily as work proceeds. Once the pipe is installed, the trench is backfilled to the appropriate level.

The open-cut method for rivers and water mass is a bit more complex. The watercourse crossing is carried out by introducing damming and over-pumping or by using flume pipes installed in the watercourse bed. Figure 1 indicates the operation of flume pipes in open-cut pipeline crossings over rivers.

Figure 1: Example of Flume Pipes (AquaDam, n.d.)

The crossing site is prepared by stripping the topsoil from the banks and installing a flume pipe bridge. Flume pipes are installed to handle the full flow of water. Excavation proceeds, often using the method of pumping water over the site to facilitate trenching. Once the trench is completed, the pipeline is installed, and backfilling is carried out. Backfilling is done using excavated subsoil, free of large stones, combined with the stored riverbed materials. Finally, the banks are restored to their original condition, and the flume bridge and piping are removed.

3.3 Trenchless Crossings

Several trenchless crossing techniques exist, including:

- Auger Boring

- Grundoram

- Tunnelling, including Pipe-Jacks

- Microtunneling

- Horizontal Directional Drilling (HDD)

3.3.1 Auger Boring Method

The use of an auger bore is efficient with crossings of short to medium length (i.e., up to 120 m). This method of crossing entails excavating pits on either side of the crossing to assist with the pipeline installation. The type of crossing determines the depth of the excavations. Dewatering and sheet piling are safety measures that often need to be considered.

The excavated pits consist of a launching pit and a receiving pit on either side of the crossing. Additional land is frequently required to accommodate the excavations. An auger is then used in conjunction with a pipe string, where the pipe string is installed in the respective location after being lowered into the pit by an overhead crane.

Figure 2: Auger Boring Representation (National Grid, 2014)

3.3.2 Grundoram Method

The Grundoram method is used for short crossings, such as drains, minor services, and minor roads, and is particularly suitable for soft ground conditions. This method employs a pneumatic piston to drive a pipe from the launching pit to the receiving pit. The risk of ground settlement is low when using this method, as no overcutting of the tunnel occurs during pipeline installation.

3.3.3 Tunneling Methods

Tunnelling methods typically include:

- Pipe Jacking

- Microtunneling

- Direct Pipe Installations

3.3.3.1 Pipe Jacking Method

This method is similar to Grundoram and involves ramming/thrusting an open-ended pipe underneath an obstacle. Mining and mechanical methods remove the soil at the end of the thrust. Pipe jacking is mostly used on large-diameter installations or for installing a concrete carrier sleeve. The carrier will be much larger than the pipeline itself, and the welding and installation of the pipeline will then be done inside the carrier. Once the pipeline is installed, the pocket between the pipeline and the carrier will be filled with grout.

3.3.3.2 Microtunneling Method

Microtunneling is similar to pipe jacking and uses a steerable remote-control pipe jack. This method requires additional land because it requires a launching and receiving pit. Management of drilling fluid will also be of concern with micro tunnelling.

Concrete jacking pipes are placed at the rear of a micro tunnelling machine fitted with a cutting head. The cutting head will be lubricated with mud and water, possibly adding bentonite to lower friction further. The excavated material and the lubricating slurry are removed through a slurry pipe. As the drilling hole progresses, extra piping segments are attached from the launching pit until the concrete pipe reaches the receiving pit. The pipeline is then inserted into the precast concrete sleeve.

Direct piping is an alternative to micro tunnelling, which utilizes a conventional pipeline instead of a concrete carrier sleeve. The following image represents micro tunnelling.

Figure 3: Microtunneling Representation (National Grid, 2014)

3.3.4 Horizontal Directional Drilling (HDD)

Horizontal Directional Drilling (HDD) is done by drilling or boring a pipeline underneath a crossing. This results in the pipeline emerging at a target point opposite the crossing. Large areas of land on either side are necessary to accommodate the equipment, drilling fluid management, and the laydown areas for the pipeline. A pilot hole is usually drilled and enlarged to accommodate the pipe. Once the drilling operator is satisfied, a “pulling” head is at”ached t” the drill, and the pipeline is pulled through the tunnel. This method of crossing can be utilised in crossings such as rivers or where multiple crossings are required, and trenching becomes infeasible. Figure 4 represents the operational procedure for an HDD crossing.

Figure 4: Horizontal Directional Drilling Schematic

(National Grid, 2014)

3.3.5 General Crossings

General crossings can also include the following self-explanatory crossings:

- Pipe Bridges – especially when bridges for pipelines are already installed

- Road Crossings (via expansion loops) – especially at refineries and depots. or processing plants

- Lowering of Pipes into Water Crossings – similar to some subsea pipeline installations

3.4 References

AquaDam. (n.d.). Fluming with AquaDam. Retrieved from AquaDam. http://aquadam-europe.com/fluming.html

National grid. (2014). Crossing Methods. The Yorkshire and Humber (CCS Cross Country Pipeline) Development Consent Order.

4 Multi-Product Pipelines: Environmental Considerations

Rapid worldwide growth has been in using pipelines to transport various products, but they have gained prominence in liquid fuel and gas. Pipelines are the most environmentally friendly way to transport various products worldwide, as they are more effective and efficient than their alternatives. The importance of pipeline transportation is hardly recognised. Most pipelines are buried underground. Some may think underground pipelines are not associated with environmental problems, but the risk of improper management is always present. Today pipeline operations are relatively safe, but it is important to remember that the risk of disruptions will always be there and may occur. Acknowledging the potential for risk means acknowledging the possibility that disruptions and occurrences can occur, which may severely impact the pipeline, its supplies, and the environment.

Multi-product pipeline transportation of products such as fuel and oil has a direct environmental impact. Without proper management and effective risk assessment, these impacts can become severely harmful to the natural environment. Environmental monitoring and management are crucial given the nature of the products transported and the associated risks (e.g., leakages, spillages, and explosions).

Legislation regarding pipelines or linear activities must adhere to the National Environmental Management Act 107 of 1998 (NEMA) principles and its associated Listing Notices 1, 2, and 3, specifying various activities’ thresholds. These regulations bind all organs of state that could potentially harm the environment. NEMA’s principles ensure the practical application of constitutional environmental rights, provide a framework for environmental management and implementation plans, and guide state actions related to environmental protection.

Thus, NEMA principles apply to all pipeline-related regulations and decisions to minimize environmental risks. Moreover, NEMA is a guideline for promoting sustainable development in pipeline construction and operation.

By applying the South African NEMA principles, it will help to determine:

- Whether a Full Environmental Impact Assessment (EIA) or a Basic Environmental Impact Assessment (BA) is required by identifying which activities are triggered under Listing Notices 1, 2 or 3, where Listing Notices 1 and 3 indicate a BA and Listing Notices 2 a full EIA.

- Whether or not an activity will positively or negatively impact the environment, ensure that these impacts are carefully evaluated to protect the environment and the quality of life regarding human life and species in the vicinity and beyond.

- If the activity contributes to sustainable development

- Which specialist studies need to be conducted

The NEMA principles relating to sustainable development state the following:

- Ecosystem disturbance, loss of biological diversity, environmental pollution and degradation, waste generation, and disruption of landscapes and cultural heritage sites must be avoided. Where these impacts cannot be entirely avoided, they must be minimized and remedied.

- The use and exploitation of non-renewable natural resources must be responsible and equitable, with careful consideration of the consequences of resource depletion.

- The development, use, and exploitation of renewable resources and the ecosystems they support must not exceed levels that compromise their integrity or sustainability.

- A risk-averse and cautious approach must be applied, recognizing the limitations of current knowledge regarding the consequences of decisions and actions (the “precautionary principle”).

- Negative impacts on the environment and people’s quality of life must be anticipated and prevented. Where prevention is not possible, such impacts must be minimized and remedied.

As more pipelines are proposed worldwide, concern grows regarding their impact on the landscape. Wetlands, in particular, will always be a challenge in pipeline construction. Wetlands are generally considered important habitats on account of the roles that they perform in an environment. Typically, a wetland area can be defined using a combination of three key parameters (Wetlands Delineation Manual, US Army Corps of Engineers 1987):

- Soils

Soils are present and classified as hydric or possess characteristics associated with reducing soil conditions.

- Hydrology

The area is overwhelmed either permanently or periodically at mean water depths of ≤ 2m or the soil is saturated to the surface at some time during the growing season of the prevalent vegetation.

- Vegetation

The prevalent vegetation consists of macrophytes typically adapted to areas with the hydrologic and soil conditions described in the preceding definitions. Due to morphological, physiological, and/or reproductive adaptation, hydrophytic species can grow, effectively compete, reproduce, and/or persist in anaerobic soil conditions.

Effectively, the pipeline construction through wetland areas requires a combination of techniques and methods to be used as a standard along the rest of the pipeline route. These are specifically designed to minimize within hydrologically and ecologically sensitive areas. The objective of pipeline development should be to ensure that the construction process incorporates the measures required, ensuring the continued integrity of the wetland habitats along the route. Pipeline design and construction should include measures to protect wetland areas and minimize the impact on the environment and all living organisms that may be affected by pipeline construction.

Many times, pipeline construction commences, and an endangered species stops construction halfway along the route. An endangered species could stop a pipeline construction for months and sometimes decommission the entire project, so the correct specialist studies need to be conducted before construction commences.

Many environmental aspects could affect a pipeline project, so the correct measures must be taken beforehand to identify all the possible challenges. If done correctly, an environmental impact assessment (EIA) will address these challenges.

Public participation is one of the major challenges during an EIA for a pipeline project. Public participation is an important requirement during all Environmental Impact Assessment Processes and could be the most difficult phase of the entire assessment process. Under section 33(1) of the Constitution, everyone has the right to administrative action that is lawful, reasonable and procedurally fair. The NEMA principles require decision-making openly and transparently, with access to information provided by the law (NEMA section 2(4)(k)). This requirement applies to the constitutional rights to access information and just administrative action. This phase requires the assessment practitioner to liaise with all Interested and Affected Parties (IAPs), especially those affected along the pipeline route. In most cases, farms and heritage sites are affected along the route, and farm owners could delay the impact assessment process due to certain risks that could damage their farms in several ways. Once again, sustainable development is very important during pipeline construction.

Section 32(1) of the Constitution provides that everyone has the right of access to (a) any information held by the state and (b) any information that is held by another person and that is required for the exercise or protection of any rights. The public’s access to the public determines whether all stakeholders can participate in those decisions that affect them meaningfully and act as a check on administrative actions. Because of the many stakeholders likely to be fundamentally affected by pipeline development, all stakeholders must be provided with complete relevant information to allow for informed and impartial decision-making during the process. The project must gain the trust of the public. In other words, to ensure that the IAPs are involved in every process step.

5 Multi-Product Pipelines: Leak Detection

5.1 Introduction

The integrity of pipelines presents unique challenges. Their long length, high value, high risk and often difficult access conditions require continuous monitoring and optimization tenancy interventions. The main concern for pipeline owners comes from possible leakages that can have a severe impact on the environment and put the pipeline out of service for repair

5.2 Pipeline Leak Causes

Leakages can have different causes, including excessive deformations caused by earthquakes, landslides or collisions with ship anchors, corrosion, wear, material flaws or even intentional damage. Other causes include but are not limited to;

- Fatigue cracks are one cause. They occur due to material fatigue and are often found on longitudinal welds.

- Tensile strength can cause stress tears, reducing the effectiveness of Cathodic corrosion protection systems and resulting in pipeline corrosion.

- Cracks can also be caused by hydrogen indexing. In this case, atomic hydrogen diffuses into the metal grid of the pipe wall, forming molecular hydrogen. This can make the pipe material brittle and prone to early failure.

- Material manufacturing errors can also cause leaks, such as when cavities are rolled into the pipe during production.

- Lpipe’san also occur when an external force acts from the outside;

The cost of failure to detect the leaks results in;

- Loss of life and property

- The direct cost of lost products and lie downtime

- Environmental clean-up costs

- Possible fines and legal suits

Pipeline leak detection systems can be categorised into major types: continuous and non-continuous systems.

| Leak Detection System | ||

| Non-Continuous | Continuous | |

| External systems | Internal systems | |

|

|

|

- Non-Continuous Leak Detection systems

- Inspection by helicopter

The helicopter flies along the pipeline, looking to detect any outflowing gas. Three common methods when detecting leaks by helicopter include detection using Laser, Infrared cameras and “leak sniffers”. When” using lasers” for leak detection, a laser is set to the absorption wavelength of the medium to be detected. Some of the laser energy is absorbed when the laser hits the medium. The energy absorbed from the laser is measured to determine the amount of leaked medium.

Leak sniffers draw in air samples to evaluate them in an analysis, which directly measures the concentration of the leaked medium.

-

- Smart pigging

Pipeline pigs are utilised for a variety of tasks in pipeline integrity management. This includes cleaning the pipelines, separating product batches, and gauging pipeline conditions. It can help gain valuable information about corrosion, cracks, wall thickness, and pipeline leaks. In this case, we use the term smart pigging. A pig is inserted into the pipeline using a pig launcher to perform pigging. The pig advances through the pipeline, propelled by the medium and gathers data along the way. A receiver is used to guide the pig out of the pipeline to analyze collected data subsequently. Various techniques are used to collect pipeline information using smart pigs; the most common are the magnetic flux leakage method and the ultrasonic principle.

The magnetic flux leakage method uses a strong permanent magnet to magnetize the line. Any changes to the pipe wall, such as corrosion, change the magnetic flux lines, which are then recorded by sensing probes attached to the pig. Following pigging, the recorded signals are evaluated based on reference signals to detect any defects or abnormalities in the pipe wall.

The method based on the ultrasonic principle involves the pig transmitting ultrasonic pulses into the pipeline wall and receiving their reflected signals. The signals are reflected by both the inner and outer pipe walls, and based on the pig’s running speed, the thickness of the pipe wall can be derived.

-

- Tracking dogs

Another non-continuous solution for monitoring leaks is the use of tracking dogs. These dogs are specially trained to recognise certain compounds injected into the pipeline for inspection. The pipeline is then operated as usual, and the dog is led along the right-of-way path, sniffing for the compound. Tracking dogs usually only takes place with short pipelines or segments of the pipeline. It is also a good method when it is impossible to localise using other methods accurately, and then the dogs can narrow down the leak site further. However, it is difficult to certify a tracking dog as a leak detection system within the framework of API or TRF.

- Continuous Leak Detection Systems

- Fibre Optic Cables

The use of fibre optic cables for the continuous external monitoring of leaks is based on physical changes at the leak site. One of those physical changes is a typical change in the temperature profile. The fibre optic cable is placed along the pipeline to detect such changes. A laser then emits pulses reflected by molecules in the fibre optic cable. The reflected laser pulse magnitude gives insight into the temperature at the place where the photon hits the molecule. By adding these reflections, a temperature profile can be made, and it is then possible to detect the characteristic change in temperature that occurs at the leak site.

Figure 1:Fiber Optic Leak Detection

-

- Acoustic systems

Acoustic sensors are installed outside the pipeline to detect leaks by measuring the noise levels at multiple sites along the pipeline. This information is used to create a noise profile of the pipeline. Deviations from the baseline noise profile that is created result in the leak alarm. Acoustic sensors can be mounted directly to the pipeline or coupled to the pipe wall using steel rods for underground pipelines. A large number of acoustic sensors are needed to monitor longer pipelines. Small leaks whose acoustic signal is small and only differs slightly from the background noise cannot be detected; otherwise, there would be many false alarms.

Figure 2:Acoustic Leak Detection

-

- Sensor hoses

A semi-permeable hose is installed along the pipeline when using sensor hoses. In the event of a leak, the medium escapes from the pipeline and enters the hose. At the start of the pipeline, a test gas is injected into the hose in a timed cycle. The contents of the hose are then pumped to the end of the pipeline, where an analysis is performed to detect the presence of hydrocarbons. The time it takes for the test gas to travel from the inlet to the end of the pipeline determines the total run time. The leak’s location can be identified by comparing the arrival time of the leaked medium and the test gas.

Due to their material-specific properties, sensor hoses are typically limited to short pipelines. This method is highly sensitive and capable of detecting even the smallest leaks. Similar to fibre optic cables, special care must be taken during installation to ensure the sensor hoses are properly positioned above or below the pipeline.

Figure 3:Sensor Hose Leak Detection

-

- Mass/Volume balance method

Figure 4:Mass/Volume Balance

-

- Statistical systems

Statistical leak detection systems subject a previously determined variable to a statistical test. Common statistical variables include pressure change over time and the result of a mass balancing. The so-called hypothesis test is widely used here. With this test, two hypotheses are prepared, namely:

- a) Hypothesis H0: No leak

- b) Hypothesis H1: Leak

The system checks whether there is enough data for the statistical variable to be plausible in the leak hypothesis and, if it is, sends out an alarm.

Figure 5:Statistical Analysis

-

- RTTM-based systems

Real-Time Transient Models or RTTM systems can compensate for dynamic changes. To do this, they make use of basic physical laws which the pipeline must obey:

- The conservation of mass principle, which includes the density ρ, the time t, the flow velocity and the pipeline location coordinates

- The conservation of momentum principle, which includes the flow velocity v, the time t, the pressure P, the pipeline location coordinates s, and the pipeline friction fs

- The conservation of energy principle, which includes the enthalpy h, the time t, the density ρ, the pressure P, and the specific loss performance L

These physical principles precisely describe the stationary and transient behaviour of the pipeline’s flow. Using these equations, flow, pressure, temperature, and density can be calculated and integrated in real-time for each point along the pipeline. These trends are also known as hydraulic profiles and accurately predict the true performance along the entire pipeline.

Figure 6:Real Time Transient Model

5.3 Leak localisation is critical when leaks occur in pipelines; it is not enough to know that a leak has occurred; you must also know where it is located. Several methods can be used to do this. Internal leak detection systems include:

- Gradient Intersection Method

- Wave Propagation Method

- Extended Wave Propagation Method

-

- Gradient Intersection Method

The Gradient Intersection Method uses the pressure profile along the pipeline to localize a leak. Ideally, the pressure drop is linear in a horizontal pipeline without elevation changes. However, if a leak occurs, the flow increases before the leak site and decreases afterwards. This results in an increased pressure drop before the leak and a decreased pressure drop after it, forming two lines with different slopes on the pressure profile. Following these lines to their intersection can determine the leak’s location.

This method’s advantages include its ability to localize both spontaneous and creeping leaks and good accuracy during stationary operation. However, its weaknesses include reduced accuracy over long pipeline lengths and poor performance during transient operations. Additionally, in non-model-based systems, variations in height, cross-section, and pipe friction along the pipeline must be considered, as these physical attributes can cause nonlinear pressure drops unrelated to leaks.

Figure 7:Gradient Intersect Method

-

- Wave Propagation Method

The Wave Propagation Method uses the sound velocity of the pipeline medium. Spontaneously occurring leaks create a negative pressure wave that propagates in both directions of the pipeline at the speed of sound. Pressure gauges at the inlet and outlet record these pressure waves, and we obtain the time the pressure wave reaches the sensors.

The differential time of arrival of the pressure wave can now be obtained from these points in time. If the pressure wave arrives at both sensors at the same time, that would mean that the leak was in the middle of the pipeline as the wave propagates in both directions at the speed of sound of the media, and if we assume a uniform density travels at the same speed in both directions. The Wave Propagation Method boasts good accuracy during stationary and transient operation as long as operational pressure waves are compensated for. The method can be used during pumping and pauses in pumping. Creeping and spontaneous leaks that are not large enough cannot be detected with this method, as the negative pressure wave in these cases is not large enough. Also, the pressure gauges must sample quickly to measure the point in time of the pressure wave as accurately as possible.

Figure 8:Wave Propagation Method

-

- Extended Wave Propagation Method

Adding more pressure gauges can expand the wave propagation method to attain better accuracy. When a leak occurs, we obtain additional points in time at which the pressure wave reaches the sensors. By now, taking into account the sensor sampling time and the actual fluid density/sound velocity profile, the exact point in time at which the pressure wave reached the sensors can be narrowed down even further.

Figure 9:Expanded Wave Propagation

Multi-Product Pipelines

Knowing what product flows through the pipeline at any given time is interesting. Batch tracking can be performed using the leak detection system. In this case, the positions of the products and mixing zones within the pipeline are tracked. Batch scheduling allows for planned arrival times and capacities. Deliveries to individual tanks and buyers can also be scheduled. Reducing the waste of mixing products in the pipeline is also possible.

![]()

Figure 10:Multi-Product Batch Tracking

6 Multi-Product Pipelines: Pigging

6.1 Introduction

Pipeline pigs, or pipeline scrapers, are tools used in the pipeline industry to perform tasks such as cleaning and inspection. They have been used for over 80 years, with the first pigs made of wood and straw, tightly wrapped with barbed or plain wire. As the pig travelled through the pipeline, it cleaned or scraped. The wire scraping inside the pipeline produced a squeaking sound similar to a pig’s squeal, which is how the name “pig” originated (Menon, 2011).

6.2 Common Pig Operations/Types

Pigs are commonly used for (PetroWiki, 2015):

- Hydrostatic Testing—The pig allows the line to be filled with water or hydrostatic testing medium without entrapping air. The pig is inserted at the front, and water is pumped behind it, keeping the pipe full. The pig forces air out of the pipeline at the front.

- Pipeline Cleanup—Pipeline scraping/cleaning is done regularly to remove scale, wax buildup, and other types of debris from a pipeline’s inner wall to maintain high pipeline flow efficiency. Natural gas pipeline pigs are used to remove trapped liquid accumulation and generally keep the pipeline free of liquid. Entrained liquid causes higher erosion rates in a natural gas pipeline and should be minimized.

- Transportation—Pigs separate batches of different products inside a pipeline. This is required in a multi-product pipeline transporting more than one type of hydrocarbon in batches.

- Prevention of Solid Accumulation and Corrosion—This is for crude oil lines to prevent water and solids from accumulating in low spots and creating corrosion cells. It becomes particularly relevant for low-velocity lines.

- Internal Pipe Coatings – Pigs apply certain internal coatings like epoxy-based coatings.

- Inspection—One of the most frequent uses of pigs is as an inspection tool. Sizing or gauging pigs are often run after the completion of a new pipeline to determine whether there are any internal obstructions, bends, or buckles in the pipeline. Pigs can be fitted with cameras for internal viewing of the pipeline.

- Intelligent Pigs—Smart/Intelligent pigs use magnetic and ultrasonic systems to locate internal and external irregularities, such as pittings, dents, buckles, corrosion pitting, or any other abnormality.

6.3 Operation of Pigs

Pipeline pigging is achieved by inserting a pig into a pig launcher. The launcher is a type of housing connected to the pipeline, accommodating a pig. The launcher hatch is then closed, and the valves are operated to create adequate pressure and flow to release the pig from the launcher. The pig is then sent through the entire line/selected section until the pig reaches the pig receiver/trap, which is used to trap the pig. The valves are once again operated so that the pig is received in the receiver without disrupting the flow significantly. The flow will then bypass the barrel and return to the mainline. The receiver will operate this way until operators come and close the necessary valves to remove the pig. (Menon, 2011)

Coding and standard requirements specify that the receiver should be fitted with a pressure-relief device that safely removes the pressure from the barrel before inserting or removing a pig. The necessary pressure gauges should also be installed for the barrel’s safe operation. The receiver can catch and hold several pigs before an operator comes, drains the barrel, and cleans the pigs.

Piggable pipeline launching/receiving stations should be spaced reasonably from one another, typically between 50 and 70 miles apart. The pipeline should furthermore be designed with long radius shop bends and the use of barred tees. This eliminates the possibility of catching a pig at a point in the pipeline. The long radius bends should have a radius of a minimum of three times that of the mainline pipe diameter. (PetroWiki, 2015)

All mainline valves must be open-port designs and should be designed according to API-6D (Menon, 2011). Hot taps greater than 6 inches in diameter should also be barred. Figure 1 shows a general representation of a pig launcher and receiver dual station.

Figure 1: Pig Launcher/Receiver Dual Station with Associated Piping (Menon, 2011)

6.4 Operational Video

T.D. prepared the following video. Williamson accurately represents the operational procedure of a pig launcher and receiver. (T.D. Williamson, 2010)

https://www.youtube.com/watch?v=CDHtL-J1Xxo

6.5 Utility Pigs

Utility pigs can be divided into the following three types of pigs (Inline, 2017):

- Foam Pipeline Pigs are used to remove debris and water from pipelines. Foam pigs can furthermore be broken down into the following:

- Bare and Coated Foam Pigs are used for general cleaning, batching, and proving pipelines. Due to their flexibility, these types of pigs have generally been used post-construction.

- Brush Pigs – These pigs are fitted with brushes that remove material and debris from pipelines. These materials typically include corrosion deposits.

- Foam Disc Pigs – These pigs remove liquids from a pipeline.

- Mandrel Pigs—Pigs designed with a metal body. These pigs are customizable, possibly alternating various types of discs, cups, scrapers, brushes, or gauging plates. Cups and discs are added where a tighter seal is required and are very effective in removing liquids and black powder.

- Urethane Pigs – A more flexible type of pig used for wax removal or liquid displacement, constructed as a single piece of equipment. Polyurethane is a wear-resistant formulation of urethane pigs.

6.6 Pig Propulsion

A pig is propelled through a pipeline by the application of differential pressure. The differential pressure required is based on the frictional force exerted on the pig by the inside of the pipeline. Should the internal diameter of the line change, the amount of pressure via friction applied to the pig will change (i.e. with the decrease in diameter, the frictional force on the pig will increase). The pig will be held at the restriction until the pressure build-up is significant enough to propel the big forwards.

Once the pig is released from the restriction, its velocity will increase significantly, losing its seal on the inner surface to a certain extent. This, in turn, will decrease the pig’s efficiency, and some debris or liquid might be left behind in the pipeline.

Low-pressure gas pipelines tend to be more problematic. Once the pig stops inside the pipeline due to a reduction in pipeline diameter, the pressure can double that of the normal pressure. Should this occur at the end of a pipeline and there is little resistance once the pig is released, the pig can reach extremely high speeds (161 km/h), causing major safety hazards. (Menon, 2011)

6.7 Pig Trains

Pig trains are another pigging used for many pipeline operations and maintenance procedures. A pigging train consists of a train of pigs sent sequentially to achieve a certain cleaning service. An example of this entails the use of four pigs in a train to clean saltwater from a line:

- The first pig pushes a slug of clean water to eliminate/push out the saltwater

- The second pig is pushing another batch of clean water

- The third pig is pushing a glycol solution slug (the glycol is dehydrating the line)

- The last pig is propelled by nitrogen and is pushing another slug of glycol

6.8 Intelligent/Smart Pigs

Intelligent or smart pigs are internal inspection devices (in-line inspection, ILI) used extensively to inspect pipelines in service. The intelligent pig is a sophisticated form of measuring device that travels through the pipeline like a normal cleaning pig while measuring and recording irregularities in the pipe wall that may represent corrosion, gouges, and other typical pipeline deformations, known as pipe anomalies.

As discussed below, intelligent pigs can be broken down into four main types. These include the following (Menon, 2011):

- Magnetic Flux Leakage Pigs

- Ultrasonic Testing Pigs

- Shear Wave Ultrasonic Pigs

- Geometry Pigs

6.9 Magnetic Flux Leakage Pig

One of the most popular types of intelligent pigs is the Magnetic Flux Leakage (MFL) pig. Using a temporarily applied magnetic field, this pig identifies and measures possible metal loss due to corrosion, gouges, etc., in the pipeline wall. The pig travels through the pipeline and induces a magnetic flux between the onboard north and south magnetic poles.

The primary use of an MFL pig is to identify corrosive defects and indicate their size. However, the MFL pig has limited crack detection capabilities; though it can detect cracks along the pipeline’s girth welds, it cannot determine longitudinal cracks.

6.10 Ultrasonic Testing Pig

The second type of intelligent pigs is Ultrasonic Testing (UT) pigs. These types of pigs are fitted with transducers that emit an ultrasonic signal perpendicular to the pipeline surface. The signal causes an echo from the internal and external surfaces of the pipe. The signals received are compared to the speed of sound in the pipe, and the wall thickness can then be calculated.

Therefore, completing a UT test requires cleanliness regarding corrosion and wax build-up. Cleaning is especially important in the pipeline with crude and heavy oils, where paraffin build-up tends to occur.

6.11 Shear Wave Ultrasonic Pig

A Shear Wave Ultrasonic Pig is a modified version of the UT pig. This type of pig is designed to identify longitudinal cracks in suspended pipelines, longitudinal ERW weld defects, and crack defects. These pigs are integral to the inspection as the cracks that occur longitudinally tend to be the most dangerous. This is because the pipe’s hoop stresses the pipe directly on the longitudinal cracks—should these defects not be detected in time, the pipeline will rupture.

These pigs are also known as liquid-coupled tools. They are operated by using shear waves generated by the angular transmission of the UT pulses through a liquid coupling medium.

6.12 Geometry Pig

The final type of intelligent pigs is geometry pigs, called calliper pigs. These pigs use a mechanical or electromagnetic arm to measure the inner bore of a pipe. While transported through a pipeline, the pig uses the arm attachment to identify ovality changes, dents, and deformations. These pigs can sometimes detect changes in girth weld size or debris build-up.

6.13 Intelligent Pigging Preparations

Preparations in the pipeline must be completed before undertaking a smart pig run to accommodate the intelligent pig during its operation. These pigs are usually longer than normal pigs, and the launchers/receivers should be able to hold the intelligent pig (Menon, 2011).

- The pipeline should be cleaned before the launch of smart pigs. Scraper pigs should be run until the amount of debris, scale, wax, or dirt is less than 23 kg per run.

- A detailed pigging log should contain information such as launching/receiving times, conditions, flow rate, etc.

- Steel mandrel pigs should be used in the second phase of the cleaning.

- Another run with brushes attached to the pigs is also recommended.

- A final run with a bidirectional pig with a urethane disk and spider nose assembly should be done.

- A gauging plate attached to a pig should then determine the roundness. If the gauging plate is undamaged after this run, the pipeline will be ready for intelligent pigging.

6.14 References

PetroWiki. (2015, 06 3). Pipeline pigging. Retrieved from PetroWiki: https://petrowiki.org/Pipeline_pigging

Menon, E. (2011). Pipeline Planning and Construction Field Manual. Massachusetts: Gulf, Elsevier.

T.D. Williamson. (2010, 03 27). Pipeline Launcher and Receiver Animation. Retrieved from YouTube: https://www.youtube.com/watch?v=CDHtL-J1Xxo

inline. (2017). Types of Pipeline Pigs. Retrieved from inline: https://www.inlineservices.com/pipeline-pig-types-applications/

7 Multi-Product Pipelines: Batching

7.1 Introduction

Batches are often called slugs and refer to a batch of a specific product being transported in a pipeline. A pipeline is often utilized to transport more than one product (i.e., a multi-product pipeline). Therefore, the hydrocarbons are transported in batches to minimize the different types of hydrocarbons.

Batching can receive fuels from multiple sources and transport them to more than one destination or have multiple intermediate take-off points. The logistics behind these operations can be complex and difficult to manage without the proper planning and the necessary operational philosophies and plans. It is, therefore, important to establish a batching schedule for the various products being transported while considering the following key influences:

- Fuel destination depot/facility fuel requirements.

- Possible pipeline throughput.

- Possible fuel import/production rates.

- Tank capacities at destination facilities.

7.2 Operational Principle

To compile and complete a pipeline’s batching schedule, certain steps are required to sort out the logistics of the pipeline operation. The requisite calculations regarding pipeline size, flow rates, fuel production, and fuel consumption in areas of concern must be completed. It is, therefore, imperative to have all the relevant market information regarding supply and demand. The following steps should be followed as a baseline to sort out the logistical operation of the pipeline.

-

- Consider the depots to which fuel will be sent and analyze their availability regarding tank storage capacity. This will be one of the base factors in determining whether the pipeline operation is logistically possible. Should the tank farms not be able to meet their projected demands, additional tank construction will have to be considered.

- The fuel anticipated to be sent to the facilities should be quantified. Then it should be determined if the tank farms can receive the incoming product in one tank while distributing fuel from another. You, therefore, require enough tank storage for twice the weekly/monthly consumption in two or more separate tanks.

- Once the tank availability has been addressed, deciding between a batching process via pigging or interfacing is possible. Should the decision be made for interfacing, the tank farms require enough free capacity to utilize the storage, while pig launchers/receivers will have to be installed to use pigs for the batching.

- As mentioned earlier, once all of those have been considered and estimated, the batching schedule can be developed using a Trial-and-Error Approach.

- The Trial and Error Approach:

-

-

- Choose a batch size for the various fuels based on possible supply and necessary consumptions at the various facilities

- Schedule the batches on a timeline-based program like MS Project, with batches following each other chronologically, as depicted in Fig. 2

- Estimate whether the facilities receive enough fuel per specified time section to meet their consumption in the same time section.

- Estimate whether the fuel coming into the depot has at least 24 hours of “resting” before “consumption.”

- Calculate whether no product is coming into a tank while being distributed, i.e., don’t pump into and don’t the same tank simultaneously.

-

If all of the above-mentioned points are satisfied and the pipeline’s batching operation makes sense, then the batching procedure should be successful. Fig. 1 shows the thought process to set up a pipeline’s batching.

Figure 1: Batching Schedule Logic

The typical flow of various products in batches is shown below in Figure 2.

Figure 2: Typical Fuel Batching Procedure

The following video shows how fuel batching is done, as represented by Paradigm Alliance (Paradigm Alliance, 2016).

7.3 Types of Batching

Batching procedures are typically executed employing the following types of batching as mentioned earlier in this section:

- Batching with the Use of Pigs

- Batching with Interfacing

7.3.1 Pig Batching

Batching using pigs involves using launchers and receivers to separate product batches with pigs. This method is a cleaner alternative, as it minimizes product mixing. With pigs, the batch distribution is simpler than the interfacing approach (discussed later). Therefore, The batching philosophy can adopt a straightforward approach, where each product batch is sent sequentially, a buffer period is maintained, and the sequence is repeated.

The pipeline must accommodate pigging, with appropriate bend radii, barred tees, and the required launching and receiving facilities in place or constructed for newly designed pipelines.

7.3.2 Interface Batching

Interface batching involves interfacing between batches, so a repetitive sequence of diesel fuel is typically utilized. Diesel fuel has the highest density but is also less sensitive to minor contamination of other hydrocarbons.

Therefore, the sequence followed is to transport a batch of diesel between each other type of hydrocarbon. Furthermore, interfacing requires available tank capacity. The interfacing tanks store the portion of the mixed fuel, which is then either mixed back into a diesel tank in selected quantities or sent back to a refinery. The interface detection is done by measuring the density of the incoming fuel and switching between the respective diesel, other hydrocarbons, and interface tanks.

The following diagram is an indication of a typical schedule for interface batching.

Figure 3: Batching Schedule Representation of Interface Batching

7.4 References

Paradigm Alliance. (2016, 12 14). Batching. Retrieved from YouTube: https://www.youtube.com/watch?v=Lbqepa2lE3w

8 Multi-Product Pipelines: Interface

Multiple hydrocarbon products, such as diesel, kerosene, and gasoline, are often transported in a single pipeline. This is usually more cost-effective than using separate pipelines for each product. The different hydrocarbons can be separated with or without the use of physical separations, meaning with or without the use of pigs (or liquid plugs). In the absence of pigs, an interface forms between two adjacent products (batches), mixing and contaminating the adjacent products. The length of this interface needs to be kept to a minimum to reduce the amount of contaminated product.

8.1 Factors to Consider

Different hydrocarbon products are consecutively transported in batches in a pipeline. The interface’s length and various factors must be considered to reduce contamination between two adjacent products. These factors include:

- Velocity – interface volume growth decreases with increased flow rate.

- Density Difference – A smaller density difference results in a shorter interface.

- Viscosity – the smaller difference in viscosity results in a smaller interface volume.

- Pipe Diameter

An increase in batch size does not affect the amount of interface product but can reduce the amount of reprocessing or refining required, thereby reducing the associated costs. Contrarily, the order in which batches are transported has a significant effect on the amount of refining that is required. It is important to keep the following in mind:

- Immiscible products shouldn’t be placed

- Products with notable differences in viscosity shouldn’t be placed around each other

Interfaces are developed at the early stages of transportation. Therefore, after an interface has been established, products moving through pump stations further along the pipeline do not significantly change the amount of contamination.nd

8.2 Interface Sizing

Densitometers, which measure the specific gravity of the product in the pipeline, are commonly used to detect transitions between products and interfaces. Additionally, sound-velocity interface detectors or continuous colourimeters (which detect changes in the colour of products) can be employed. More accurate detection of interfacial changes reduces product contamination.

The length and volume of interfaces can be calculated by considering factors such as the densities and viscosities of the two adjacent products, as well as the velocity of the fluids. Since determining the exact concentration of each product within the interface is challenging, it is typically assumed that equal amounts of both products are present in the interface mixture. The density and kinematic viscosity of the mixture can then be calculated using the following formula:

The density of Mixture (ρ):

Kinematic Viscosity of Mixture (ѵ):

These values are used to calculate the dimensionless Reynolds number of the interface:

where v and D are the velocity and pipe diameter, respectively.

The Reynolds number is used to calculate the friction factor using Serghide’s method.

On the other hand, Palfrey’s method is only used to determine the length of the interface.

Thereafter, the interface volume can simply be calculated as:

8.3 What to do with the Interface

Formed interfaces must be removed to avoid degradation beyond the maximum allowable contamination of the products. After removing the interfaces, they must be reprocessed to deliver saleable products. It is, however, more economically appealing to blend the interface into one of the adjacent products by adding it to one of the products’ tanks. In products’, it is important to ensure the specifications are still met, otherwise the product will be downgraded.

Further separation is typically done by arranging products in ascending or descending order of product quality or density. The correct batching sequence can reduce the interface volume and, thus, the amount of contamination. As the requirements – regarding fuel specifications- in Africa aren’t that restrictive, the interface mixture is usually added to the diesel tank. (In Africa) Diesel is commonly used to separate products from other hydrocarbon products. In countries where the contamination criteria are more stringent, pigs will become necessary to ensure that, for example, the kerosene (with a high sulphur content) doesn’t contaminate doesn’tsel (lower sulphur content).

8.4 Interface Processing

Interfaces typically represent 5-10% of batches. The interface that must be diverted to a separate tank is referred to as transmitting; it is diverted to avoid contamination of the adjacent batches. These interfaces and transfixes no longer adhere to the required specifications and standards but cannot simply be discarded, as it would lead to a great loss in profit.

8.4.1 Transmix reprocessing

8.4.2 Regrade/Downgrade

Interfaces between common products can be mixed or “cut” into lower-quality products. The addition of the interface thus further downgrades the lower-quality product.

8.4.3 Blending

- In-line Blending – turbulence ensures extensive mixing when proportionate amounts of each component are added directly to the mainstream in a pipeline.

- Batch Blending: Additives are added during or/and before blending. Additives such as anti-oxidants or octane enhancers can provide certain properties not inherent in the hydrocarbons.

- Onboard Blending – products can be prepared to specification without onshore facilities.

Online blending (and in-line), which ensures enhanced accuracy, has become more common due to technological advancements, computerization, and the accessibility of certain equipment. Many different software packages that optimize the blending process and the production of profitable products are available.

9 Multi-Product Pipelines: Controls

Pipeline companies install components and equipment to ensure pipeline systems operate efficiently, reliably, and safely. Valves are essential parts of any piping system, controlling the flow and pressure of fluids to obtain the aforementioned operating objectives.

There are many reasons why a pipeline may need to restrict gas flow in certain areas, including emergency shutdown (safeguarding people and protecting property) and maintenance. For example, if a section of pipe requires replacement or maintenance, valves on either end of that section can be closed to allow engineers and work crews safe access.

When valves are located correctly, properly maintained, and correctly operated, it can reduce the volume of product released in the event of a pipeline failure. Valves serve to block or isolate pipeline sections for required maintenance or emergencies.

However, valves can increase system complexity and have inherent risks. Installing a valve can have an environmental impact, and the valve can have issues related to reliability, leakage, and susceptibility to accidental damage or vandalism. It is essential to assess and analyse valves’ engineering and environmental impacts holistically in the context of the entire pipeline system and the surrounding landscape. The risks could outweigh the benefits if a valve is placed in a sensitive environment.

Although several valves operate at each pumping station, the critical valves (also generally referred to as mainline block valves) in a pipeline are spaced every few kilometres along the pipeline systems. All mainline valves, such as block valves, are either operated manually, remotely or automatically:

- Manual Valve: Opened and closed by pipeline personnel on-site.

- Remote Valve: Opened and closed remotely from a pipeline flow control room.

- Automatic Shut-off Valve: Shut-off valves close automatically if pipeline pressure drops or flow direction changes. As an additional safety measure, automatic valves also can be closed manually.

The minimum required spacing of these valves is prescribed in ASME B31.8, ‘Pipeline Transportation Systems for Liquid Hydrocarbons & Other Liquids.’ Liquid pipelines have the following criteria for valve placement.

Valves are placed:

- At the suction end and discharge ends of a pump station

- On each line entering or leaving a storage tank area

- On each mainline at locations along the pipeline that will limit damage or pollution from the accidental hazardous liquid discharge

- On each lateral take-off from the trunk line

- On each side of a water crossing that is more than 30 m (100 ft) wide

- On each side of a reservoir holding water for human consumption

Additionally, check valves may be installed on grades and the downstream side of rivers and streams for more protection from backflow conditions in case of a line breach.

Most block valve installations are outfitted with automatic shutdown controls. These controls are set to close the valve if pressure or flow rates change, indicating a possible breach in the line. By having these valves spread throughout the pipeline, the amount of potential fluid leakage that might occur during a pipeline break is limited. Furthermore, many pipeline valves are designated as emergency shutdown valves (ESD), remotely operated from the pipeline control room.

Figure: Valve site for a variety of aboveground valves to control fluids in pipeline

Valve sites are rough 45m x 30 m (150 ft x 100 ft) in the area and typically remain within the pipeline right-of-way (ROW) corridor. All valve sites are designed and built to meet or exceed provincial and national safety regulations, environmental and emission requirements and fire safety codes. All valve site locations appear as small fenced areas (locked entry) within a cleared ROW unless the site is in an open field.

9.1 References

Greg Johnson, 2011, Pipeline Valves—Always Ready, VALVEMagazine.com, http://www.valvemagazine.com/magazine/sections/where-valves-are-used/4405-where-valves-are-used-pipeline-valvesalways-ready.html?showall=1&limitstart

National Energy Board, 2016, Fact Sheet: Valves on a Pipeline, https://www.neb-one.gc.ca/bts/nws/fs/vlvpplnfs-eng.html

10 Pumps

Pipeline transportation is the most economical and reliable method available for transporting large amounts of liquids and gaseous commodities. However, when transporting products of different physical properties, such as petrol, diesel, and Jet A1, in the same pipeline, the situation becomes more intricate due to the complicated pressure characteristics along the pipeline.