One of EPCM’s major focus areas is modularization for African hydrocarbon pipelines. As a company, EPCM services the whole African continent. From the beautiful beaches of Cape Town in the South to the rocky outcrops and rift valley as far north as Djibouti.

Being very experienced in delivering projects in Africa, EPCM also understands how to make our lives easier in these areas. One of the major ways this can be done is to understand modularization. Although it sometimes costs a little bit more from a CAPEX perspective to skid mount certain equipment, it saves all this and more during construction.

EPCM started as an oil and gas business and has recently expanded into other chemical and industrial process plants. Its core is built on years of cross-country oil and gas pipelines and tank farms. Thus, EPCM is very familiar with remote locations, changing construction environments, and stranded infrastructure that needs to be supported.

When considering modularization for hydrocarbon pipelines, EPCM developed three levels to better define and understand the process.

The first level of modularization is where the complete unit can be supplied in modular format—the unit is completely prefabricated in the workshop and delivered as a single unit to the site. From a modularization perspective, this is complete modularization. However, this is not always possible, as location and logistics play a major role.

The second level of modularization involves skids made up of a certain facility. The skids are then shipped to the site and assembled to create the final unit. Although this is not complete modularization, it also works well and considers logistics and location.

Level 3 of modularization is where no skids are manufactured. The equipment and materials are sent to the site individually and assembled on-site. The level of modularization does, however, have certain OEM (original equipment manufacturers) components skid mounted and supplied to them from the OEMs in this format.

In this article, EPCM will discuss the major items that can be supplied in modular format for hydrocarbon pipelines.

1 Modularization for Hydrocarbon Pipelines: Pump Stations

One of the major components of any hydrocarbon pipeline is the pump stations. These stations move the product from point A to point B. Although it sounds like a simple task, there’s much more to it. Depending on the pipeline’s length and diameter, several pump stations might work together to move the liquid fuel through the pipeline. In most cases, a pump station would consist of at least two large pumps; one would always be running, and the other would be on standby. Where two pumps cannot meet the demand of the pipeline, it can be increased to 3 pumps, with two running and one on standby. For the pumps to have the correct inlet pressure called NPSH (Net Positive Suction Head), the pump station would either have small booster pumps feeding them, or the static head of the tanks would be enough to provide the larger pumps with enough pressure. Another important component of a pump station is understanding what drives the pumps. When the pump station has electricity nearby, it would be the cheapest option to connect to the existing power grid. This will then require large electric motors to be fitted to the pumps and connected to the power grid. The typical electric power needed for large pipeline pumps would be 1MW per pump. Even with electricity, the pump station would still need backup power; in this case, one or two backup generators would be included in the pump station design. These generators would be designed to start automatically if the pump stations have a power trip. In very remote areas without power, pump stations can be designed to run directly from diesel motors. Thus, the pumps are not connected to an electric motor powered by the generator but directly to a diesel-fired engine. This would reduce energy losses but would then be very limited to future power connections as the utility companies expand to cover the remote areas.

Although pump stations have a few more components, this article focuses more on their modularization and will thus only discuss the major components.

1.1 Level 1

When we look at the pump station design, you have a few levels of modularization. Level one would be a complete modular pump station with all its components. You would have a plinth, electrical, and pipeline connection points available on site. The pump station would arrive as a complete skid or even a containerized solution on-site and would then get connected. This would be the perfect world of modularization, and in many cases, it can happen exactly in this fashion. Typical examples of pump stations that work this way are smaller ones that can fit everything into a container (or, worst case, an abnormal load). Larger pump stations can also be used – these are usually situated directly next to the ocean, where a large vessel could transport the station and drop it into position without driving on any roads. Unfortunately, in Africa, you do not find many of these perfect locations. When level one modularization does not work, you can move on to level two.

Level 1: Complete modular pump station

1.2 Level 2

In level two cases, you split your pump station into multiple skids. So, you would, for instance, have the pump already connected to the electric motor skid mounted and ready to slot into its position on site. One of your pumps and its motor would be skid mounted and fit on the back of the truck delivering the pump. Your inlet piping and booster pumps would be another skid already welded and assembled in the workshop. Your outlet piping and metering would form another skid that can be assembled with the rest of the pump station. The skids would be delivered and fitted like Lego blocks to assemble the pump station. This is a very practical solution for Africa and is used regularly on cross-country multi-product pipelines. In certain cases where pump stations are close to existing towns with skilled resources, a level 3 modularization could also work.

1.3 Level 3

Level 3 modularization is the least amount of modularization. This is mostly done where skills exist around the facility where the pump station would be installed. Most items would be bought as separate loose-standing items installed on-site. A skilled workforce would have to assemble and build this pump station. The area where modularization would still occur would be, for instance, the generator sets – the contractor on-site would get a complete generator with the engine and generator already assembled. He would probably not try to fit actuators to valves, and the pumps would already be fitted to the electric motors and laser-aligned by the OEM (Original Equipment Manufacturer). He would thus do most of the assembly and even welding on site as part of his construction and not have skids that he would assemble.

Level 3: Modularization.

All three levels of modularization can work for pump stations in Africa, but the strategy would have to be decided during the design and planning phase of the project. Using BIM (bill information modelling) principles during the design of these stations would help the team identify the level of modularization needed.

2 Modularization for Hydrocarbon Pipelines: Compressor Stations

Compressor stations are very similar to pump stations but are used to move gas from one point in a pipeline to the next. The big difference between gas and liquid is that liquids cannot compress, and gas can. In gas hydraulics, the compression factor thus needs to be taken into consideration. From an infrastructure point of view, compression stations are very similar to pump stations and have the same general layout. The gas that enters the compressors needs to be clean to prevent damage to its structural integrity.

Furthermore, when gas is compressed and the pressure increases, the gas’s temperature rises. This means that, usually, after the gas has passed through a compressor, it has to be cooled down to a temperature that falls within the system’s design limits. Compressors can be electrical, diesel, or gas-driven, but gas is usually preferred owing to its cheaper burning costs.

As discussed in the pump station section, gas compression stations could also be executed using either of the three levels of modularization. Level one would be the best for small stations that can fit on the back of a truck, whereas levels 2 and 3 would be applied to larger stations depending on the location and the skilled resources in the area.

Level 2 and 3 combined: Compressors to be skid-based, etc., piping to be installed onsite

2.1 Customer Metering Stations (CMS)

Customer metering stations are most commonly used in distribution networks. You would have the large transmission pipelines with their metering systems used for leak detection and billing purposes. Then, you would have a distribution network with hundreds of small users all using gas, for instance. The gas would thus be taken from the transmission pipeline, the pressure dropped using a pressure-reducing station (PRS) and then fed into a distribution network running at a lower pressure. At each of the customer sites of the distribution network, you would have CMS stations that measure the amount of gas the customer uses, and the gas company bills them accordingly. These small CMS stations could have one or two legs depending on the client’s availability requirements. CMS stations can easily be skid-mounted or containerized and shipped to the site. From a gas company perspective, standardising these units makes a lot of sense as they often have to maintain meters and exchange spares.

CMS stations could thus be modularized using level 1 or level 2. In some cases, contractors still prefer to build them on-site, but this is becoming less common as technology and logistics improve. One thing to consider during these installations is that the meters sometimes have a long lead and might have to be slotted in at the end of the fabrication or even on-site.

Level 1: Skid base metering installation

Level 2: Spool piece metering installation

3 Modularization for Hydrocarbon Pipelines: Pressure Reduction Stations (PRS)

As with CMS stations, the PRS station is used in transmission and distribution networks. It can be used for any product, but most of the time, it’s used for gas networks. When a gas pipeline needs to drop the pressure, they install a pressure-reducing station. As with a CMS station, it can have a single or double leg. Most customers prefer to have double-leg stations to improve availability. These stations are usually designed to have a control valve in each leg with a shutoff valve downstream from the control valve. The shutoff valve is set at a pressure slightly higher than the bottom end of the control valve – if it reads at a higher pressure, the shutoff valves close, and the gas is directed to the alternative leg. This way, the problem in the original leg can be sorted out before it’s used again.

Depending on the gas pipeline, PRS stations can be large installations. In many cases, the gas needs to be heated before the pressure can be dropped. This is due to the Joule Thomson effect, which reduces the temperature of the gas when the gas pressure is reduced.

From a modularization point of view, the small PRS stations can most certainly be skid-mounted or even containerized and sent to the site. Thus, level one would work very well for the small gas pressure-reducing stations.

Level 1: Skid mounted PRS installation

As the size of the PRS station increases, it might be necessary to move towards levels 2 and 3 of the modularization process. In two-leg stations, each leg could be spool pieced and sent to the site. On-site, the two legs get assembled and connected to the rest of the installation. It might be that the heating skid would have to be installed separately and then connected to the whole system.

As with most of the skids discussed in the document, many factors will influence the level of modularization. But standardizing the design and trying to skid mount as much as possible makes a lot of sense for pressure-reducing stations.

4 Modularization for Hydrocarbon Pipelines: Cathodic Protection

Cathodic protection is a very specialized area of cross-country pipeline design. Many factors, such as soil resistivity, stray currents, proximity to existing power lines, pipe area and material, and pipeline coating, play an important role in designing a cathodic protection system for a pipeline. Two major cathodic protection systems can be installed when all factors are considered. The first one is called ICCP (Impressed Current Cathodic Protection). The ICCP system uses electricity from the grid, solar or generators to drive a current through a TRU (Transformer Rectifier Unit). The TRU converts the AC power to DC and decreases the voltage to the required voltage. The current then flows from the TRU to silicon iron anodes installed into deep wells that will be drilled close to the TRU location. The typical depth of a deep well is about 60-100m. The electrodes then move from the silicon iron anodes through the soil towards the pipeline. If the pipeline has any damage to the coating, the electrodes will collect on the pipeline and prevent it from rusting.

The second cathodic protection system used in pipeline design and construction is the sacrificial system. In this particular case, magnesium anodes would be installed and connected to the pipeline every few hundred meters. They have no electricity connected to them and depend on the natural flow of electrodes from the magnesium anode to the steel pipe. If the pipeline coating gets damaged, the electrode will flow towards the steel, thus protecting the pipe from rusting.

Both systems have positives and negatives depending on the location and specific pipeline design.

From a modularization point of view, both systems can be supplied in modular form to pipelines.

ICCP stations could be supplied as level 1 modularization. However, the complete system would probably be level 2 modularization, as the deep wells and anodes would have to be separately delivered and installed. The whole power supply, TRU, and monitoring device can be containerized and supplied as a complete container or skid. The deep wells would have to be drilled separately, and then the anode tails with silicon iron anodes could be a module that fits into the deep wells.

When we consider the sacrificial system, it would probably have to be installed as a level 3 system, with each sacrificial anode system installed separately. However, you will have a certain amount of modularization, with the test points that can be assembled in the workshop and the anode tails that can be fitted before installation.

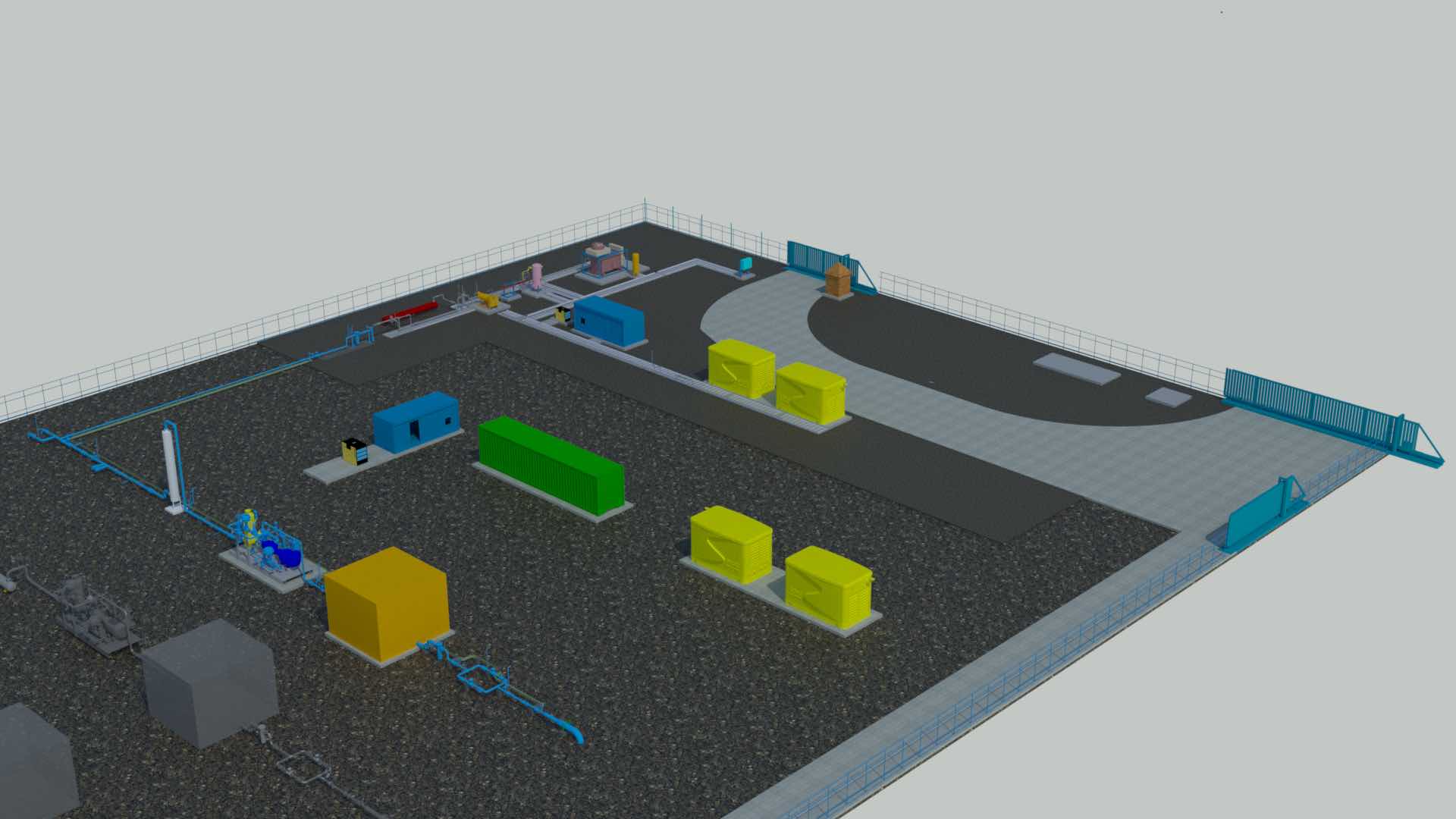

Complete installation of the CP system. Combination of level 1 – level 3

5 Main Line Valve Stations

When designing a hydrocarbon pipeline, the placement of valve stations is very important. In general, the design codes give good guidance, although they don’t all agree on the distance between valve stations. In the American code, the maximum distance between valve stations for a gas pipeline is about 32km. In the Australian code, they leave it open to the engineer, but in some cases, they go as far as 100 km from each other. In ASME 31.4 that governs multi-product fuel pipelines, they also only give guidance, with authority given to the engineer to make the final decision. They do, however, explain why you have valve stations and where you should look at installing mainline valves.

In summary, the most important reason mainline valves are installed for cross-country pipelines is to keep the amount of product that can be lost during rupture to a minimum. Safety is a major driver when considering valve station placement, and ASME 31.8 gives you classes based on the population around the pipeline. If the area is densely populated, you need to have more valve stations compared to when the area is not populated. Environmental impact is another major driver of mainline valve placement. For multi-product pipelines, ASME 31.4 requires mainline valve stations to be placed on either side of a river crossing or wetland to ensure minimal spill if a rupture occurs.

The normal design of a mainline valve station usually has a large full-bore ball valve installed in the line. This allows the pipelines to still be pigged but shut off can easily and quickly be obtained by closing the ball valve. Depending on the location and control philosophy, the mainline valve can be activated or not. If the valve is actuated, it can be done electrically, hydraulically or pneumatically. Again, this depends on the product, location and utilities available at the valve station. Another component of mainline valve stations is the bypass line and valve. When commissioning pipelines or sections of pipelines, the bypass valves are used to equalize the system. If the pressure difference is too high between the two pipeline sections, the torque needed to open the mainline valve will be very high, and operators will battle to open the valve. In gas pipelines, when they commission sections and one section has high pressure, and the other is still low, the Joule Thomson effect causes a major temperature to drop in the gas. They thus use the bypass lines to regulate the pressure and flow to prevent damage to the mainline valve.

Mainline valve stations can be buried under the ground with extended spindles, installed into a valve pit, or raised above the ground with 5D elbows as needed. The pipeline engineer selects the correct layout for a mainline valve station and should consider several factors when designing it.

Modularization of mainline valve stations would always be a good idea. The remoteness and size of these installations make them a perfect fit for modular fabrication. Depending on the size of the bypass line, mainline valve stations could either be modularized at level 1 or level 2.

When the level 1 modularization principle is used, the complete valve station, including the bypass line, actuator, and instrumentation, would be installed in the workshop, and the complete assembly would be transported to the site and installed.

Level 2 would allow the mainline valve station to be installed using a few spools that get welded together on-site. Most of the assembly would be done in the workshop, with some final welds done in the field.

In certain cases, the contractors might choose to use level 3 modularization, but we would not recommend this unless they have a specific reason this works better for the exact location.

Valve station

6 Control Rooms/Data Centers

The control room of a pipeline forms the heart of the operations. From this room, the pipeline owner can inspect the pipeline’s operations and control various items on the pipeline. The control rooms work with the fibre network to control all pumps, compressors, valves, and storage facilities. It has several alarms and warnings to ensure the system is functioning as it should. A lot of development is going into improving the user interface, and recent developments include mobile applications to control pipelines and plants. With the movement from voice to data, data centres are becoming increasingly popular to lump with control rooms. These data centres thus store and process all the pipeline data. With clever tools like Watson, the data can now be processed into meaningful patterns to improve pipeline operation and maintenance.

Depending on the size and location of the control room or data centre, these items are regularly modularized. Both data centres and control rooms are made up of hundreds of small electronic components talking to each other. It would thus be very difficult to assemble all these components on-site.

Although control rooms are mostly in existing buildings, the bulk of the components are assembled in workshops, and modules are sent to the site to fit into existing buildings.

This market is mostly dominated by large international companies that offer a complete solution to the problem and all their equipment.

Control room and data centre equipment would mostly be installed using level 1 or level 2 modularization, and we would also not recommend using level 3 modularization for these systems.

7 Pig Launchers and Receivers

Pig launchers and receivers must be installed to clean, commission, or inspect pipelines. Pig launchers and receivers are usually installed at pump stations or compressor stations. The norm is to have a pig launcher and/or receiver for every 100km of pipeline. However, these days, the latest intelligent pigging technology seems to collect up to 200 km of pipeline inspection information in one run. Intelligent pigging is governed by the design codes and the laws of the country where the pipeline is installed. In most cases, pipelines must be pigged every 5 years to inspect wall thickness and ensure they are still safe to operate. If pipeline companies find defects during the pig runs, they have to repair them to ensure the integrity of their pipeline is still intact.

The physical pigging station is not very complex but forms an important part of the pipeline. Pigging facilities are usually above-ground installations, and, in many cases, especially at intermediate pump/compression stations, the launcher and receiver are fenced in the same facility. The way a pig launcher works is it uses the product in the pipeline to propel the pig, pig stations thus have a barrel-like a rifle that has a door on the one side and is connected to the pipeline on the other side with a double block and bleed valve between the barrel and the pipeline. It then has a kicker pipeline that directs some of the product behind the pig to propel it forward. Once the door is closed with the pig inside the barrel, the valve at the kicker line opens, and the product propels the pig into the pipeline.

Pig launchers and receivers are perfectly suited as modular components in pipeline construction. In many cases, pipeline companies choose to have the launchers and receivers mobile, moving them from one scraper station to the next. Quick-opening doors are also a very nice extra, and if the budget allows it, we would recommend adding them to the design.

In most cases, pig launchers and receivers are supplied as level 1 modules that the pipeline contractor can install as a whole.

You can, however, also do a pig launcher as a level 2 modularization. The best split between the two skids would probably be to do the launcher barrel, door and valve as one skid, have the kicker line and its valves as the second skid, and assemble the skids on site.

If the project wants to investigate a level 3 modularization, it would probably be the best option to completely fabricate the launcher on site as it does not have many components that will fall into a level 3 modularization.

Level 1: Skid-mounted pig launchers and receivers

Level 2: On-site assembly of launcher/receiver

8 Fibre Optic Systems

Communication has always been a challenge for cross-country pipelines. In the early years of pipeline design and construction, they would only dream of having all the ends of the pipeline talking to each other. As technology improved, pipelines started pushing towards different communication methods, from standard telephone communication to radio to fibre optic. These days, most pipelines either have fibre optic installed or are busy looking into retrofitting fibre optic lines into the pipelines. The fibre optic cable is installed in a duct on top of the pipe. The cable usually has about 32 fibres that can be used for communication. In general, a pipeline communication only uses a few of these fibres; the remainder then gets sold to the telecom companies, and the fibre line becomes a second income for the pipeline company. The fibre optic cable uses light signals sent via the fibre to give signals as needed between the ends of the pipeline. By using fibre optics, the pipeline operator can give signals to open and close valves, shut down pumps, and provide a time of arrival for products, for example. The latest technology with fibre optics is called intrusion detection. The fibre uses acoustic sensing to detect interference in the pipeline and can pinpoint where the intruder is digging or driving over the pipeline. This is especially helpful in areas where 3rd party intrusion is high, like West Africa and Mexico.

The fibre optic system will run for the full length of the pipeline. The duct that houses the fibre is installed during the construction, and the fibre is blown in afterwards. This way reduces the damage caused to the fibre during the pipeline installation. Inspection pits are installed every few hundred meters. When the intrusion detection systems are installed, a black box gets added to the fibre installation every few kilometres. This handles the acoustic sensing of the fibre system.

Although fibre is essential to ensure communication on pipelines now and into the future, it’s not a very modular installation, and most fibre optic systems would probably be installed using level 2 or 3 of the modularization process.

9 Filter/Dehydration Stations

Filter skids are used widely in the hydrocarbon pipeline industry. In certain industries, like the aviation industry, the cleanliness of the product must be maintained. In general, most pipeline systems are designed to have a filtering system before they enter a facility and as they move to the next portion of the facility. Filter systems are also very common in protecting specialist equipment. In gas pipelines, for instance, the gas is filtered to less than 2 microns before it can power the gas turbines, as any large particles can damage the turbines. Filter skids are often seen before compressor stations to ensure compressors are not damaged. During pigging operations, most of the dust and debris in the pipelines are removed utilizing a pig, which needs to be removed from the system at some stage. Filter skids are perfect for this, and as part of the pigging exercise, they are usually connected to the kicker lines at the pig receiving facilities. When gas is found at wells drilled in the ground, it’s usually wet and has particles trapped in it as part of the stream. Filtering and dehydration skids work perfectly to clean up the gas before moving it into the gas-gathering network. The most common filter skids use cyclone filters to remove the larger particles and then use candle-type filters to remove the smaller particles. When dehydration is needed, desiccant dryers are often employed to remove the water from the system.

Filter skids are perfect for modular fabrication and installation. Although they can also get relatively big, most of the time, a typical filter skid can fit onto a truck and be transported to the site. Thus, level 1 modularization would work very well when it comes to filter and dehydration skids. In some cases, contractors might choose to go with level 2 modularization due to size or location, but you would seldom see a level 3 modularization approach taken on remote filter skids.

10 Modularization for Hydrocarbon Pipelines: Heating Stations

Heating skids are most commonly used in gas applications, heavy fuel oil, and crude oil applications. When the pressure of a natural gas pipeline or system is dropped, the Joule Thomson effect also drops the system’s temperature. The rule of thumb for these calculations is 0,5 degC for every 1 Bar pressure dropped. Heating skids are thus very often used before pressure reduction stations are installed. The most common heating skids use water bath heaters that get heated by burning the gas or using electricity. The water bath heater heats the gas to the required temperature before the pressure drop reduces the temperature again. In some of the latest PRS (pressure reduction station) designs, the energy from the pressure drop is converted into electricity, which is then used to power the heating system. Another application where heating skids are frequently used is HFO (heavy fuel oil) installations. As with crude oil, the product does not flow easily, and if it’s not heated, the viscosity blocks the pumps and filters. Heating skids are used in this particular application to keep the product at the correct flowing temperature. With certain pipelines that transport waxy crude, the whole pipeline must have heating pads or stations to ensure the product can flow as required. Heating skids play an important role in the oil and gas industry and should be engineered correctly to ensure the system’s integrity.

Modular heating skids are very common and can be skid-mounted or containerized. Thus, heating skids would be great for level 1 modularization but could also be modularized up to levels 2 and 3 as needed.

11 Modularization for Hydrocarbon Pipelines: Cryogenic/Cooling Stations

During the compression of natural gas, the reverse Joule Thomson process occurs, and the natural gas is heated as the pressure increases. Usually, aftercoolers are installed downstream from gas compressors. These aftercoolers are usually part and parcel of the compressor skid you purchase from the OEM compressor supplier, and they specify the outlet temperature from their skid. It’s thus already modularized as part of the compressor package you purchase. Aftercoolers are also used to exhaust the gas of engines or burners. Burners often have waste heat that is then recovered by boilers or condensers. Condensers or boilers are also basically aftercoolers; they take the heat produced by something and convert it into a different phase by cooling it down.

An additional cooling technology, cryogenics, takes cooling to the next level. Cryogenics occurs when products are taken below 0 degrees C. At a temperature of -161 degrees C, natural gas changes from gas to liquid in atmospheric conditions. The latest trend in gas pipelines is to install small liquefaction plants on the pipeline that liquefies the gas. Once the gas is liquefied, it’s moved to different locations where pipelines cannot reach. LNG (liquid natural gas) is the process of liquefying natural gas. LNG consists of the liquefaction process, where gas is turned into LNG, and the regas phase, where the LNG is turned back into natural gas. The liquefaction and regas skid work perfectly in the modular form.

When cooling and cryogenic skids are evaluated, both work well with level 1 and level 2 modularization. Level 3 could work for certain applications, but it would overcomplicate the site construction process and potentially delay the project.

To all knowledge

To all knowledge