This article has been republished with EPCM with the kind permission from our marine structure pipeline partner – Krah Pipelines.

Despite advancements in tangential extrusion technology for mandrels, many clients, engineers, and contractors still favour conventionally extruded, solid-wall PE pipes for marine projects. This preference often stems from a lack of awareness about Krah Marine Pipes (KMP), which have been successfully utilized in numerous high-profile projects worldwide.

KMP – Outfall pipeline DN/ID 3400 mm

We carried out marine projects for desalination plants, power plants, sewage treatment plants and other intake/outlet pipelines. Here, we used Krah Marine Pipes with structured and solid (pressure) walls.

Nothing speaks against solid wall conventional axially extruded pipes, which have been familiar for many years—as they were the state of the art for many years. “Familiarity” means that, in general, no big effort is needed to design and install this well-known “stuff.”

Unfortunately, Krah Pipe Producers Worldwide still needs to convince engineers that our pipes suit this application. From a cost point of view, we are a very attractive solution—not only for the pipe but for the complete project, including ballasting and sinking. So, we must improve our marketing and technical documentation to move from a niche market player to the main player.

1. Marine Structured Pipelines KRAH – History

Tangentially extruded pipes, theoretically and practically, should be equally familiar. Companies like KWH, Bauku, Henze (including Chinese copies) and others have been producing several types of ribbed/profiled pipes, low pressure, high ring stiffness, destined mostly for landlines, fittings, manholes and storage tanks applications since the 1970s.

In the 1980s, ribbed or profiled pipes were tested in a few outfall projects, but they proved unsuitable and too costly. The main challenges included inconsistent wall thickness along the waterway, inadequate fusion of the profiles, lack of high-quality jointing methods, and the high costs associated with low extrusion output and the limitations of extrusion technology at the time.

The structural design was continuously developed and covered mostly by the DIN Standards, but until the late 1990s, we were speaking of single-wall pipes with ribs/profiles.

Since the end of the 90s, Krah has developed a new homogenous pipe with correct waterway wall thickness and proper jointing. Together with high production output, the pipe was, and still is, a very successful solution for all kinds of marine pipes. Many large-size projects were realized worldwide by companies like PPA&KRAH, Krah-Pipes, HENZE, FRANK, Krah Estonia, Krah America Latina, Krah Chile, Krah Egypt, Polyplastic, Polypipe, UGPM Oman just to name a few. The largest diameter achieved to date is in Argentina, with an internal diameter of DN/ID 3600 mm, fully joined by electrofusion and successfully deployed underwater. Previously, axially extruded PE pipes were typically used only up to DN/OD 1600, with an SDR17 rating, due to limitations in production and engineering capabilities.

2. Today

Today, conventional axially produced pipes are manufactured up to DN/OD 3000, and advances in engineering now allow for an SDR of 33. For Krah pipe producers, the updated 2018 DIN 16961 standard remains foundational for technical guidelines. Many other international standards, such as ASTM F894, IRAM 13414, and JIS K 6780, have adopted the older version of DIN 16961 as a national standard. Standard double-wall pipes, regulated up to DN/OD 1200 by EN/DIN 13476 or ISO 21138, are not suitable for marine pipe applications due to the unique demands of these environments.

A few engineers started to implement the possibility of using structured wall pipes for marine applications, using the geometrical and mechanical properties of the structured wall (moment of inertia, waterway wall thickness, buckling resistance).

A closed profile for Krah Marine structured Pipes (double chamber wall, super high stiffness)

For installation in the marine environment, the axial load capacity and bending resistance are more important than the ring stiffness alone. Therefore, it is intuitive why the real double-wall structure (KMP) sections are more suitable for marine use.

A well-calculated double-wall structure can be designed with a requested equivalent SDR (eSDR), and a ring stiffness can exceed the SN values of solid wall pipes with that typical SDR. It is also possible to produce exactly the required ring or pipe stiffness. The waterway wall thickness can be produced exactly according to the applied working pressure. Today, a Krah Marine Pipe (KMP) is a tailor-made solution that can economically realise marine pipelines.

The developments started to follow two directions: pipe wall construction with single—or multi-layer profiles or walls with square or round chambers. Both are extruded on mandrels with spirally applied layers (“tangential extrusion” is the technical term in the standards—here, Krah production technology).

Further details on the various properties and specifications of KPM can be found in DIN/PAS 1065:2007-11, titled “Spirally Wound Pipes Made from Polyethylene (PE 100) – Tangentially Extruded – Dimensions, Technical Requirements, and Tests.” This standard outlines essential dimensions, performance requirements, and testing procedures for KMP pipes.

As the Krah Group, we have decided to proceed in a relatively new way: by defining a structured wall that can be easily dimensioned to obtain the characteristics necessary for marine projects.

The KMP – Krah Marine Pipe – is a “real” double wall pipe, presenting two thick, continuous layers and internal chambers/profiles that are alternatively circular and rectangular (or a combination of both). Today, corrugated pipes (produced on a corrugator, not on Krah production technology) are also called double-wall, but they are not “real” double-wall pipes; they have not the availability to handle internal working pressure, they have no pressure-resistant joint, and their bending characteristic are not homogenous.

KMP – wall structure

The Krah-Marine Pipes (KMP) always have a homogenous and smooth inner layer. It is not a pipe welded by prefabricated square profiles. It always has a socket and spigot and does not end in an open profiled spiral.

The pipe is weldable, and fittings and manholes with the same wall structure are easily produced.

Every pipe has a solid wall electro-fusion socket, a double wall area and a solid wall spigot.

Krah Marine Pipes (KMP) are available from DN/ID800 mm up to DN/ID5000 mm. The standard pipe length is 6 m, but the pipes can be pre-jointed at the production facility to increase the installation speed. Depending on the client, all pipes can have an inspection-friendly inside surface. Krah Pipes, in general, is available from DN/ID300.

3. Calculation

Our standard calculations are based mainly on the following approaches, according to existing standards and covered up by references and experiences. A third-party engineering company can and should always check our proposals.

3.1 Hydraulic capacity

All Krah Marine Pipes are calibrated on inner diameter – so nominal diameter DN is the internal diameter ID. That means the inner diameter does not change if the wall thickness increases. We are often faced with misunderstandings regarding the nominal diameter and the meaning of inner and outer diameter. Our nominal diameter is the hydraulic diameter.

Tangential and axial extruded pipes are the effect on the hydraulic diameter.

For example:

A Krah Marine structured Pipe DN/ID 2000 provides an inner diameter of 2000 mm for all stiffness and pressure classes!

A conventional direct extruded pipe DN/OD 2000 always provides a significantly lower inner diameter than 2000 mm and is related to SDR class/wall thickness:

DN/OD2000, SDR 21, PE 100 (stiffness approx. SN 12, PN 8) => hydraulic diameter of ID 1808 mm

DN/OD2000, SDR 26, PE 100 (stiffness approx. SN 6, PN 6) => hydraulic diameter of ID 1846 mm

That means to be competitive in hydraulics to a Krah Pipe DN/ID 2000, a much bigger DN/OD pipe must be considered:

DN/OD2200, SDR 21, PE 100 => ID 1990 mm

DN/OD2200, SDR 26, PE 100 => ID 2030 mm

A difference in inner diameter directly affects the velocity and flow characteristics. Together with the quality of the inner surface, the diameter defines the pressure loss for the volume flow rate.

3.2 Working / Operation pressure

Krah Marines Pipe (KMP) are standardized for pressure load capacities according to DIN 16961 and DIN PAS 1065. For decades, Krah Pipes have been used for pressure load applications, and now they are finally respected and described in the standard.

Instead of mentioning only a “design pressure”, we highly recommend differing between operating pressure and real stiffness. The real stiffness must result from technical calculations and not only a “choosing” of stiffness class according to ISO9969. It makes no sense to large-scale old realized projects with small pipe diameters. The price difference is huge; technically, a large scaling has no positive effect. Reduce the project costs by calculating and not by copy-paste!

The inner (waterway) wall of Krah Marine Pipes is designed according to real operating and pressure conditions. We face no inner pressure for intake lines, but for outfall lines, the Maximum Operating Pressure (MOP) is decisive! We can design the Krah Marine Pipes for any inner pressure without limitation. However, the inner wall thickness increases with increasing pressure resistance, making it less efficient.

Remember: The increase in the wall thickness of KMP does not affect the hydraulic diameter of the pipe!

It is commercially and technically recommended that the inner wall be designed according to the real working conditions. Don’t ask for a high “design pressure” when you have special needs for the sinking process or pipe backfilling.

Extract DIN16961:2018, Attachment D

3.3 Pipe stiffness

In the past, we have realized many projects where complete pipe systems were installed underground, with a very difficult ground situation and complicated backfilling. We can and do consider the backfilling and installation of the pipeline after the sinking process. We provide a full structural calculation of the pipes according to international standards.

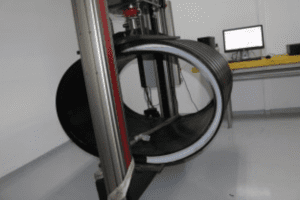

Testing of the pipe stiffness and flexibility (30% deformation)

3.4 Buoyancy

Concrete ballast blocks are typically used for polyethene pipes to avoid buoyancy.

Of course, this is also available and standard for Krah Marine Pipes. Normally, the concrete blocks are positioned every 6 meters. The slightly profiled outer wall is an advantage to direct extruded pipes, especially at the joint. That reduces the risk of slipping to zero percent, even at big changes in temperature and because of that a shrinking of pipe diameter.

Here, you see concrete blocks mounted in the pipes.

Cheap blocks without any screws can be used; the blocks are linked to the pipe structure by using concrete.

A very cost-effective solution for the blocks

Another smart and patented solution is the partial filling of profiles with concrete/grout. The second spiral fills the Krah Marine Pipe structure with concrete/grout. That means the pipe is still semi-flexible and can be bent easily, but it is heavy to reduce or eliminate concrete blocks. The second “load” spiral can be filled partly. The filling can be done at the factory or in the short term before installation.

A smart solution – a partially filled KMP

The bending radius depends on the wall structure and filling but can reach values of two times the unfilled Krah Marine Pipe profile. If all chambers are filled (one spiral solution), the pipe must be handled as a fixed, rigid beam.

Because it partially fills with the defined distance, the Krah Pipe remains semi-flexible and provides all the benefits of a typical S-curve installation.

3.5 Bending

Krah Marine Pipes are designed for a 50 x pipe diameter bending radius. We consider the strain of outer fibre and buckling resistance in design. Because of the stiff pipe wall structure, Krah Marine Pipes provide the highest safety against buckling.

Many finite element analyses were carried out – including the bending behaviour of the joints.

FEM – Analysis of a bent Krah pipe

Krah Marine Pipes are produced from high-quality PE 100, which has the best strength and stability characteristics. These proven values are used in all our calculations.

A bent Krah pipe

Our nice combination of flexibility and stiffness will give the Krah Marine Pipeline a perfect response to seismic ground movements, which often happen after installation. Several tests have been done; details and independent test reports can be requested at Krah-Pipes in Germany.

3.6 Allowable pulling forces

At Krah Pipes, an electrofusion process homogenises the axial wall thickness. The joint is designed for the same load as the pipe wall itself. There is no weak point in the complete pipe string, and no separate reduction factor must be considered. For the pulling force only, the minimum axial connected wall thicknesses are considered, even because a “spiral”—in our case, a double spiral—can handle pulling forces too—so we consider this aspect a special safety to our marine solution.

3.7 Marine Structured Pipelines KRAH: Jointing

The real Krah Marine Pipe double-wall structure gets homogeneously jointed by an integrated Krah electro-fusion process. The Krah Marine Pipe electro-fusion joint guarantees a strong connection between the pipes. Because inner and outer wall are joined by electrofusion a perfect load transition is assured for all occurring stresses/loads. Also, the stiffness of the jointing area is higher than the stiffness (requirements) of the pipe itself. Compared to butt-fusion, another large benefit of an integrated electro-fusion joint is that KMP has no NO-sagging of pipe – to provide a better, safer and quicker installation.

Krah welding equipment for large pipes

As you can see in the picture above, the KMP joints need “only” little E-fusion devices and no expensive butt-fusion machines. For every joint made, the machine can print a detailed jointing report to have a full set of QC documents.

It is funny that Krah-Electro-Fusion fittings were used to repair conventional PE pipes when butt–fusion machines weren´t possible. So, it seems even our competitors trust our electro-fusion joint, and they are happy.

3.8 Marine Structured Pipelines KRAH: Fittings and Specialities

Krah Marine Pipes produce all kinds of fittings (bends, reductions, branches, diffusers, etc.) and manholes/intake towers with the same technology and jointing. This has been one of the core businesses for these kinds of pipes since the 1980s. To fabricate these fittings, stronger wall constructions are usually used to handle the welding factors and other properties.

An integrated stub-end for a flange connection

A stub-end (for flanges the pipe strings to each other) can be a direct part of the pipe.

Even the flanges can be tested by FEM.

It is kind of funny that many conventional PE pipe producers are using Fittings, Manholes, and Stub Ends produced by tangential extruded technology—mainly Krah pipes (and they don´t mention this in their specs). So, even our competitors trust the homogenous wall structure of our fittings for sensitive elements of the pipe strings.

Fittings (bend) for an outfall project

Intake chamber design

3.9 Sinking

During the planning and calculation of the sinking process, other effects in the design can occur, like string lengths, waves, currents, wind, speed of installation, using floaters, etc. These will affect the calculation mentioned above conditions and will be considered there.

The photo above shows the floaters used during the deployment by PPA&Krah in a project in Peru

4. Marine Structured Pipelines KRAH: Production technology

By the way, the same Krah machines can also produce solid wall pipes in maximum diameter of DN/ID 5000mm; with the same normalization – EN12201 – of axially extruded pipes, besides structured wall KMP pipes. It is easy to reach a homogenous solid wall thickness of 200 mm to 300 mm (with no sagging, voids, or blisters). The production technology can be extended to all interested Krah pipe producers who will produce Krah Marine Pipes under Krah’s supervision and license. The latest production line, called KR800-max, continuously controls the homogenous wall structure.

Production line KR800 – MAX – able to produce KMP up to DN/ID 4000mm

The production area needed is only 20m x 30m x 6m– so it is quite easy to move or set up a plant close to the project site. This will increase the speed of the installation, lower transportation costs, and reduce the possibility of “forgotten” parts.

5. Marine Structured Pipelines KRAH: Summary

Krah-Marine-Pipes (KMP) are available from DN/ID1000 up to DN/ID4000 mm in the length of 6m. The pipes are produced out of polyethene PE100 and can have a co-extruded yellow inspection-friendly inside surface. An integrated special electro-fusion joint does the joining of the pipes. The pipes can be designed according to the project requirements concerning working pressure, stiffness, bending ratio and pulling force – to guarantee the price and quality optimum for a marine project.

Price- and quality-wise, Krah Marine Pipes (KMP) are a very attractive alternative to other marine pipe materials, like GRP, steel, concrete and, of course, to conventional solid wall PE pipes. The market of large diameter pipes for a marine application is huge, so the Krah Group will concentrate its network (today approx. 50 Krah-Pipe producers worldwide) to provide a good solution for the clients for their desalination-, power-, treatment- plants or any other marine application in the future. Complete design software for Krah Marine Pipes (KMP) should be available in 2019, and we will have a tight and close relationship with several international engineering companies to support the final customer and build a solid foundation of technical experience and documents. We will join the experience and documents from our network partner, and be more present in global projects.

To all knowledge

To all knowledge