1 Introduction to Hydraulic Fracturing – Geomechanics

HYDRAULIC FRACTURING – GEOMECHANICS: Fracking, as a technique, was born in the 1830s, with the use of acids to fracture the reservoir rock. In 1947, studies to change acids for water began; in 1960, the use of dynamite in its base state, which is nitroglycerin, was being tested on the coast of the United States. But it was not until 1998 that hydraulic fracturing began to be used commercially, thanks to George P. Mitchell, the father of the fracking technology.

According to a study conducted by the IEA, which states that thanks to technologies such as fracking, by 2019 the United States will produce more oil than the largest producer in the world, Saudi Arabia. In 2020, that is a fact. Despite the benefits in terms of production offered by hydraulic fracturing, whether for fracturing source rocks or reservoir rocks, the technique’s difficulty generates high implementation costs. Because of this problem, new alternatives are sought to face the heterogeneity of the formations.

Geomechanics, being one of the branches of geology, is shown as one of the scientific alternatives to decipher formations’ behaviour where the fracking technique would be practised. Below it is detailed how geomechanics can be an essential ally when talking about hydraulic stimulation.

2 Hydraulic Fracturing – Geomechanics: Fundamentals of Fracking

Hydraulic stimulation consists of the injection of a highly-viscous fracturing fluid, at a pressure above the pressure of the fractured formation, intending to change the skin factor, looking for negative values. That is to say, to generate flow channels or fractures around the drainage area, placing in the generated channels elements in a packaging form that help the fracture to take longer to close and generate sufficient permeability for fluid passage.

During the process, the fundamental concepts of the operation must be taken into account, which are:

- Rupture pressure: It is the point at which the formation fails and breaks; this point is above the elastic capacity of the rock.

- Pumping pressure: It is the pressure necessary to extend the fracture, keeping the good flow rate constant.

- Instant closure pressure (ICP): This pressure can be read when the fluid injection stops, and all friction pressures disappear; at that time, the formation returns a part of the fluid that was pumped to it at a certain pressure: this is the ICP.

- Well flow rate: It refers to the pumping time represented in the total volume of the fluid; this allows inferring directly the size of the fracture created; at the same time, it allows identifying the number of additives, proppants, and control fluid used.

3 Fundamentals of Geomechanics

Geomechanics is closely related to the main currents of geology, classical mechanics, and mechanics of materials. Despite being widely used in the mining and civil engineering sectors, geomechanics is positioned as an excellent ally for operations in the oil and gas industry.

It is based on the calculation of the stress field that exists in equilibrium in the sub-soil. It expresses the maximum stress, the minimum stress, the overburden stress, and the shear and sliding stresses that exist.

Soils behave under the action of loads as elastic materials, in some cases, greater deformations than the regular ones are produced, having to turn to calculations that take plasticity into account. For the oil and gas industry, it is crucial to understand the nature of the shear strength to create a simulation or prediction of the different problems that may arise under certain types of operations.

4 Geomechanical Model

The geomechanical model consists of an explicit description of data relevant to the construction of oil wells and the production of the same; these include pore pressure, state of the stresses, mechanical properties and strength of the rock for the total stratigraphic section penetrated by the wellbore.

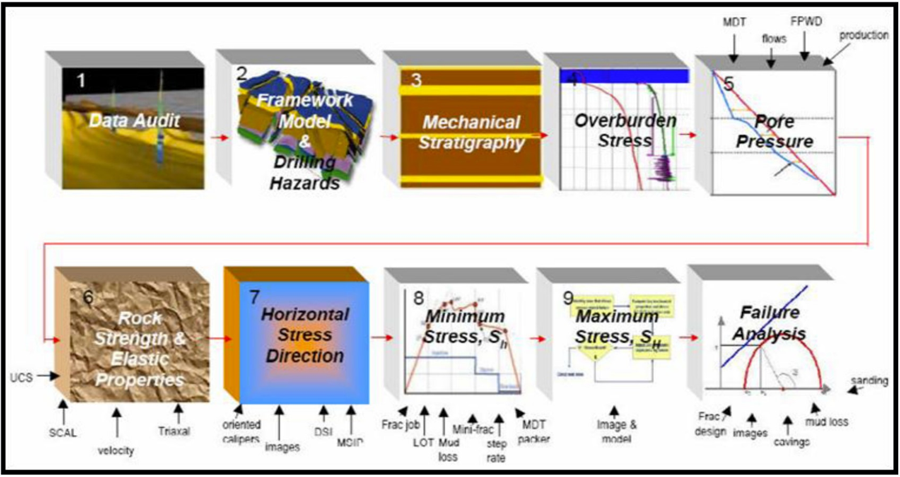

Today, for the construction of a geomechanical model, different methodologies are used. One of the most used is the one by geomechanical engineer Marcelo Frydman. In his methodology, he details processes such as:

Additionally, a geomechanical model can be calculated in two ways; one of which is a dynamic model, where all the calculated resources depend on indirect data, such as taking records or area iterations to create data simulations; and static models, these are characterized by using core samples and direct data from the formation.

5 Geomechanics, an Ally for Fracking

Geomechanics is shown as an ally of high importance when facing the heterogeneous challenge that a hydraulic fracturing represents. Each reservoir is a new world for fracture specialists. Every wellbore is a new adventure since the conditions of pressure, temperature, rock strength, and elastic rock conditions do not necessarily keep a homogeneous behaviour. Due to these factors, the use of data from the construction of a geomechanical model is a high-impact ally.

5.1 Data audit

During geomechanical modelling, an inspection of the behaviour of the reservoir is performed, analyzing each wellbore. During this process, possible operational problems related to borehole stability are searched, as in turn, it is identified if the wellbore was fractured.

If the wellbore was fractured, data such as fracture pressure, type of fluid used, type of control fluid, and proppants used to maintain the fracture are detailed, as well as the closing pressure and well flow rate that the wellbore registered. It also analyzes the functionality of the fracture over time and how much the wellbore’s skin factor was achieved after the process. These data provide a background of the events of the reservoir.

5.2 Framework model

The stratigraphic framework helps to understand how old the rock and what type of rock it is and where the work is going to take place. For example, rocks belonging to Eocene ages are characterized by being hard rocks and with a high degree of compaction. It is understood that the deeper, the more compact and resistant type of rock is expected in theory.

5.3 Mechanical stratigraphy

One of the processes practised within stratigraphic mechanics is taking petrographic samples. This type of task is performed with the use of direct core samples, which are analyzed using a petrographic microscope. This type of direct analysis allows going beyond the electrical or special records made in a wellbore. They provide knowledge of factors such as:

- Grain selection: This parameter refers to the type of grain that predominates in the formation, the types of grains are classified into:

- Very good: In this section, the grains are uniform among themselves, maintaining shape, size, and composition.

- Good: Unlike the previous one, the good grain differs in one of the scenarios, it can have a good composition and size, but it varies in shape.

- Moderate: It is the balanced point of grain types. In this section, a transactional shock is common to be observed when the study area is close to an age change.

- Poor: The poor grain is characterized by meeting one of the characteristics: size, shape, or composition, but it does not have a positive behaviour in one of the other two conditions.

- Very poor: It is characterized by a heterogeneous composition. It is common to see it in formations that have undergone migrations or that are still young in terms of depth.

For good fracking, the types moderate, poor, and very poor are optimal because they reflect less amount of opposition to the fracture. In turn, their deformities help the adaptation of flow channels.

- Differences of porosities: With petrographic analyses, we obtain a 2D view of the flow channels that are in the formation, this type of porosity is punctual and not effective, but to have a variety of samples along the producing area of the oil well, similarities are noticed depth traces, this helps to choose more functional stages when practising fracking, and in turn, it allows predicting which area will have a better behaviour before hydraulic stimulation.

- Contact between grains: the type of contact between grains is a property rooted at the time the sediments were deposited in the area, there are different types of contact:

- Sutured: It refers to the roundest grains in the area.

- Concave/convex: This type of grain tends to have half-moon shapes.

- Longitudinal: These grains are characterized by having a linear formation longer than a wide one.

- Tangential/punctual: These grains have the main characteristic that one part of them is rounded, and the other is smooth.

- Floating grain: This type of contact is characterized by being away from other grains. It is attached to the cementing material of the rock and is surrounded by it.

For fracking processes, knowing the type of grain helps in the decision of the proppants that should be used to avoid slipping processes, size, and shape. The use of proppants of a much larger size than those of the formation would cause spaces in the pore throats created with the fracture. It would facilitate the detachment of the grains of the formation by the effect of fluid friction, occupying the spaces created by the proppants, thus creating slipping over time.

5.4 Direction and magnitude of STRESSES

The stresses operating in the sub-soil are divided into three main stresses: the overburden stress (Sv), the maximum horizontal stress (SH), and the minimum horizontal stress (Sh):

- Sv > SH > Sh: Normal regime

- SH > Sv > Sh: Transcurrent regime

- SH > Sh > Sv: Reverse regime

In turn, horizontal stresses have preferred routes in the sub-soil; this translates in directions of preferential flow, porosity, and natural fractures in the formation of study. They are opposite and are obtained by the practice of 6-arm or so, oriented calliper records, or image logs, or sonic-oriented records, which allow noticing fractures in the formations.

This type of information allows the fracture specialist to have an optimal direction of fracturing. If it is in a normal regime, the recommendation is to direct the fracture towards the maximum stress, only the opposition of the fracture’s minimum effect that will have to be kept open.

On the other hand, the correct selection of the hand direction of the stress regime avoids the existence of tortuosity in the pore throats; this type of problem avoids the passage of proppant towards the fracture and, therefore, its functionality.

5.5 Overburden stress

The overburden parameter is the weight generated by the layers of formations on the target formation being studied. It is obtained by the use of density registers (RHOB) and, subsequently, Gardner’s equation is applied, and an overburden pressure reading is obtained at each point read by the register, taking into account the existence of shale

For hydraulic fracturing, the knowledge of an abnormal overburden pressure is crucial in the selection of the strength of the proppant, fracturing studies conducted in Venezuela, and Argentina, demonstrate an abnormal behaviour of the stresses, being the overburden stress (SV) equal or greater than the maximum stress (SH).

Therefore, it is established as an abnormal stress regime. If the fracture is planted in a horizontal area, the overburden stress directly affects the closure of the formation; therefore, it affects the proppant’s strength pressure. In some cases, crushing effects have been evidenced on proppants that degrade their size and become part of the production.

5.6 Rock strength and elastic properties

To obtain the results on the properties of the rock dynamic tests are carried out, which are sonic logs (DOC, DT), depending on the travel times that the sound waves take and with the use of software such as Drillworks or Skua Geolog. Profiles of mechanical properties of the rock are obtained both elastic and of resistance. These programs are based on the formulas of Horner, Eaton, and Bowers, among others.

On the other hand, there are tests of sample destruction. These are based on the sampling of the nuclei. After, tests are performed, such as:

- Unconfined pressure test (UCS): In this test, the sample is pressed vertically and unconfined, and the maximum pressure that the rock resists is read, with this test the Young modulus is calculated, which is the elasticity of the rock.

- Brazilian test: It consists in subjecting a cylindrical sample to diametrical compression, applying a load uniformly along two lines or opposite generatrices until the rupture is reached, with these tests the strength of the formation is obtained, which helps to calculate the compaction of the rock.

- Triaxial compression tests (TRX): In this test, a rock cylinder is compressed under constant containment pressure until it reaches its maximum strength. Traditionally, it is measured for a containment pressure given the maximum strength, i.e., the conditions to which the rock was in the sub-soil. From this test, we obtain the Young modulus, Poisson ratio, and Biot coefficient.

With the knowledge of the rock’s mechanical properties, it is possible to calculate the magnitude of the main horizontal stresses of the area. The minimum stress translates into the pressure required to open the rock with the fracture. To achieve a correct propagation of the fracking technique, it is necessary to know the magnitude of the maximum stress since this value is the maximum strength of the rock. After this point, the rock is no longer elastic. The fundamental objective of the fracture is achieved: opening the rock.

5.7 Failure analysis

One of the most used failure analyses in the oil industry is the Mohr-Coulomb equation; this type of test takes factors such as Biot coefficient, Young and Poisson modules, UCS values, and TRX values. To determine the angle of internal friction and the values of the rock’s cohesion, these allow the fracture specialist to estimate the values of collapse pressure and fracture gradient along the rock, either in a vertical or horizontal plane.

Knowing the cohesion value of the rock, together with the degree of compaction, allows the fracture specialist to establish an adequate type of fracturing and control fluid. Hard rock does not necessarily contain characteristics of high cohesion, so the use of a highly viscous fluid can cause problems if this characteristic is not known.

6 Hydraulic Fracturing – Geomechanics: Conclusion

Fracking technology is not a failure-safe process to full functionality, despite this, the use of the geomechanics discipline establishes a clear view about the properties and features which the fracturing fluid is going to face, as well as the proppant, which will be added to provide a lasting effect on this process. Having a profound understanding of the rock is and always will be a necessity.

7 References

- International Energy Agency, 2019, “The United States to lead global oil supply growth, while no peak in oil demand insight”,

Extracted from: https://www.iea.org/news/united-states-to-lead-global-oil-supply-growth-while-no-peak-in-oil-demand-in-sight

- Andres Ocando, 2020, “Geomechanics, the Nemesis of the NPT”

Extracted from: https://oilmanmagazine.com/article/geomechanics-the-nemesis-of-the-npt/

- Wafa Al-Kattan and N. Jasim Al-Ameri, 2012, Estimation of the Rock Mechanical Properties Using Conventional Log Data in North Rumaila Field.

- Ocando A, Osorio J, 2016, “Geomechanical characterization of the deposit B2-X-68, for fracture optimization. Lake Lagunillas, North Lake”

About EPCM

To all knowledge

To all knowledge