1 Introduction

1.1 Purpose

The technological leap in communication and information technology instigates the upsurge in smart devices, frameworks, architectures, and various industrial and nonindustrial applications. Therefore, a detailed review of IoT is proposed covering the diverse aspect of IoT promoting interoperability and energy efficiency.

Moreover, we explore the influence on IoT devices when different types of equipment are connected with these. This comprehensive technical article addresses various issues such as energy consumption, resource management, fog data analytics, heterogeneity, scalability, and the role of predictive maintenance, data science, machine learning to accomplish interoperability and energy efficiency in the industry.

Lately, the industrial IoT (IIoT) has appeared as a popular paradigm to completely reshape the automation experience towards the realisation of process automation. The IIoT delivers a set of standards to integrate a range of manufacturing equipment into a web-based arrangement and ensures valuable data to proficient systems for smart decision making. The IIoT also makes it possible to link a wide variety of tiny sensor devices installed throughout the production line to the analytic methods and strives to accomplish the following four objectives:

- First, observing data generated by sensor devices is cost-effective and energy-efficient, considering that sensors are battery-powered in nature.

- Second, processing of this data, converting it into useful information via some business analytic tools.

- Third, delivery of this actionable information to an expert personnel/system for onward decision making.

- Fourth, getting the anticipated performance enhancement by taking preventive or corrective actions based on the helpful information.

IIoT plays its role by encouraging the ultimate performance improvement throughout the production process, leading to substantial financial savings.

1.2 The Internet of Things

Various technologies such as edge computing, fog computing, big data analytics, wireless sensor network, sensor technologies, and data science technologies fused to the term “internet of things”. Internet of things (IoT) is an augmentation to traditional internet with the vast potential to provide interconnection between people, processes, software, actuators, and sensors to exchange data and interact with each other.

As per the studies done by Cisco, the number of internet-linked devices in IoT surpasses the number of the world population by the end of 2020 [1]. According to their prediction, the number of connected devices was 14 billion linked to the internet by 2018. By the end of the year 2020, the number should have reached 50 billion, and further, this number will increase to 100 billion by the year 2025. As the number of connected devices increases, so is expanding the heterogeneity among devices because IoT devices are being developed by different manufacturers lacking interoperability among them.

Figure 1. IoT trajectory. Source: “IoT Trajectory” by Cea. is licensed under CC BY 2.0.

IoT is a “co-engineered” communicative network of physical and computational components. Initially, the word IoT has been defined in context with supply chain management [2]. Then, rapidly IoT has been unfolded to the public eye, thereby becoming a mainstream topic. IoT is an ever-growing network of sensors, actuators, processes, software, smart machines, infrastructures, and servers for communication and exchange of information among each other. The “Things” in an IoT network refers to smart bulbs, alarm clocks, smart locks, IP cameras, thermostats, home appliances, and items embedded with biochips that are uniquely identifiable. In totality, IoT represents an intelligent connection of devices to sense, collect, and analyse data from the world around us. That’s why IoT is sometimes known as an “advanced automation and analytical system.”

In other words, we can say that IoT is an autonomous system that is connected to the internet with self-configuring, automation, and analytical capabilities without requiring any M2M or human to human interaction. Figure 1 represents, with the IoT technology, any device will be able to communicate with the internet at any point in time from any location to provide any type of service to anyone by any network.

The notion of IoT is to connect mundane devices such as actuators, sensors, embedded devices, and appliances. Data generated from IoT devices are synthesised to fuel innovative services. For interchanging information with IoT applications, a communicative infrastructure is required. It must be mandatory for IoT applications to have fair access to the communicative infrastructure.

1.3 From general to industrial applications

Some IoT applications are building automation, smart city, smart irrigation, health and fitness monitoring, connected roadways, smart parking system, and many others.

IoT holds great significance in our day-to-day activities. IoT provides a human-centric solution to assist people with disabilities. For instance, an occupancy sensor in a smart home automatically detects a person’s motion to switch on or off lights and fans without human mediation. Thus, it reduces the monthly and yearly power bills. Similarly, various types of sensors and actuators coordinate to perform the daily tasks of a smart home to save time and human effort.

In healthcare systems, IoT is utilised to determine any health conditions and abnormalities by collecting health data. The measurements taken by the wearable health devices are sent to a master node such as a smartphone. Body sensors are used for remote monitoring of patients’ health and activities. Fitbit is a device that calculates the sleeping patterns, number of steps, and calories burned during the day and night [3].

An intelligent irrigation system uses IoT devices to boost crop yield. A moisture sensor in a smart irrigation system is used to determine the level of moisture in the soil. The water flow automatically releases through irrigation pipes when the humidity of soil goes below the threshold level. Intelligent irrigation systems also collect moisture level measurements to analyse a cloud to plan water schedules for irrigation. Cultivator’s Rain cloud is a device that controls the whole process of irrigation automatically, starting from the opening and the closing of water valves to the handling of soil humidity and temperature [4].

IoT also helps in environmental monitoring to control pollution and prevent natural calamities. The deployment of sensors in affected areas help in early prediction of natural disasters such as flood, earthquake, tsunami, and thunderstorm. This greatly helps in the timely evacuation of people where such calamities are likely to occur. Moreover, IoT boosts crop yield, supply chain management, health care, and smart cities. Likewise, IoT technology is utilised in different domains to automate the tasks of businesses, industries, and management firms.

A real-time location system (RTLS) is an example of Industrial IoT. RTLS uses Wi-Fi RFID tags that are attached to materials to determine the status and real-time location. Tags provide the rate of production. The output of each assembly line is monitored in real-time. Real-time monitoring assists employees to complete and meet the targets at various stages of production. Actions can be taken to speed up or slow down production at different stages. In addition, blockages at any point of time in production are identified quickly.

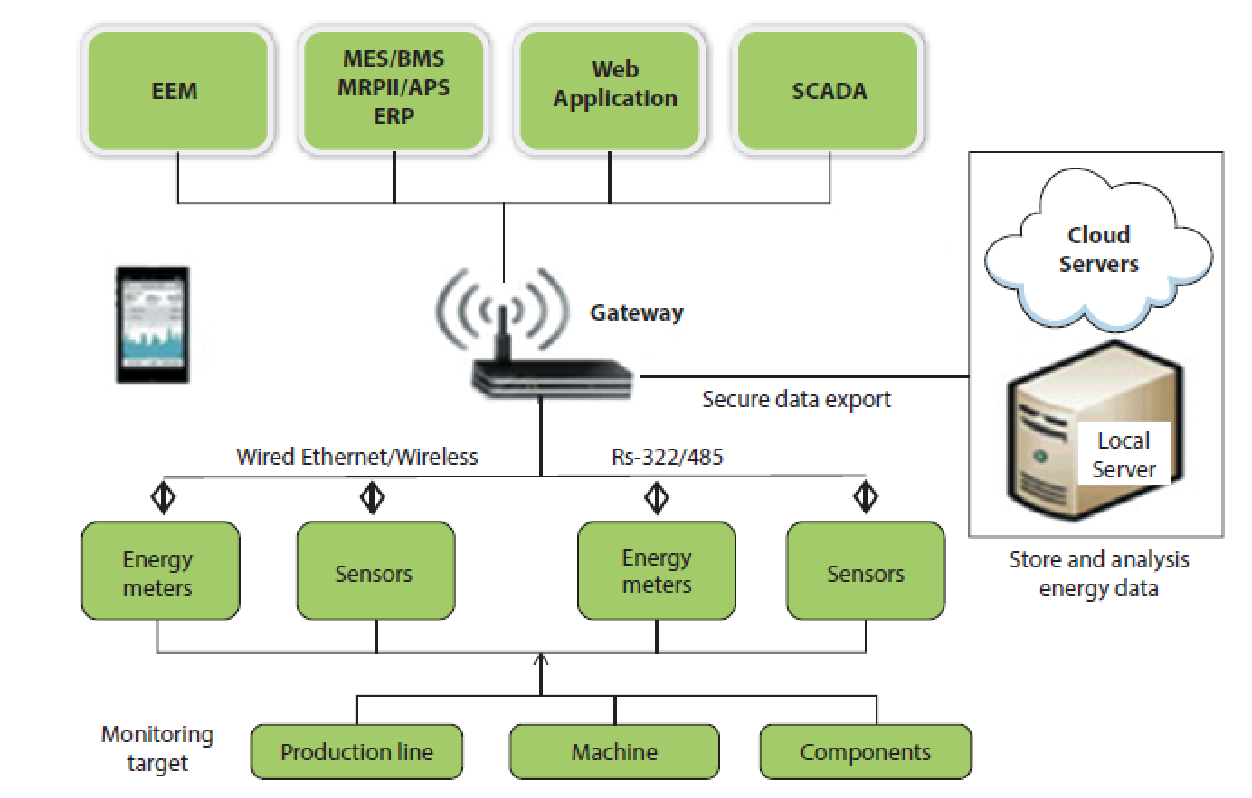

Figure 2. System structure of an IoT energy management system. Source: https://doi.org/10.1002/9781119778868.ch4

2 Industrial Energy Use

2.1 Major trends

For the sustainable development of IoT, energy efficiency is the key driving force, as stated by United Nations Sustainable Development Goals. The demand for energy increases by 4.6% in 2021 compared to 2020 globally [5]. This marks a new record as the CO2 footprint ⸺and its devastating consequences within the scope of climate change⸺ increases globally.

Nearly three-quarters of the natural gas demand growth in 2021 is from the industry and buildings sectors. In the following months, demand for renewables rose by 3% in 2020 and is also set to mount across all key sectors – transport, power, heating, and industry. With its renewables query on target to expand by more than 8%, the power sector leads the way to grasp 8,300 TWh, the most considerable year-on-year growth on record in absolute terms.

The Covid-19 emergency adds an extra level of stress. Sadly, global improvements in energy efficiency have been declining since 2015 in this context of expanding energy use. Because of the crisis and the low energy tariffs that have persisted, energy intensity improved by merely 0.8% in 2020, roughly half the rates for 2019 and 2018. This is inferior to the level needed to achieve global climate and sustainability goals. It especially concerns because, over the next 20 years, energy efficiency will account for more than 40% of the decrease in energy-related GHG emissions in the IEA’s Sustainable Development Scenario, which portrays how to put the world on track to achieve international climate and energy goals in total.

The 4E TCP is a technology collaboration programme under the auspices of the International Energy Agency. The platform aims to promote energy efficiency as the key to ensuring sustainable, safe, reliable, and affordable energy systems [6]. As an international stand for collaboration between governments, the 4E TCP provides policy guidance to its members and other governments concerning energy-using equipment and systems.

This and other similar initiatives prioritise technologies and applications with significant energy consumption and energy-saving potential within the residential, commercial and industrial sectors. To meet its aims, it harnesses the expertise of governments, industry, experts and other ventures for joint research associated with the development and deployment of energy-efficient equipment.

The projected benefits gained by the rise of the IoT are significant in terms of improvement of quality of life and economic impact. Intel projected the penetration of internet-enabled devices to grow from two billion in 2006 to 200 billion by 2020, implying nearly 26 smart devices for each human on Earth. As per another estimation, the number of connected gadgets will be 75.4 billion in 2025 and 125 billion by 2030. Some firms have presented their numbers taking computers, smartphones, and tablets out of the equation. Gartner estimated, 20.8 billion connected pieces will be in use by 2020. Similarly, IDC estimated this quantity to be 28.1 billion, and BI Intelligence estimated it to be 24 billion [7].

2.2 Consumption and optimisation

In industrial settings, outdated machines consume a disproportionate amount of energy and time to produce effective output. The efficient functioning of IoT machines plays a vital role in industrial management. To demonstrate the efficiency of the functioning, the continuous monitoring of devices becomes mandatory.

An advanced machine-metameric dimension (AmD) for industrial IoT has been proposed [8]. The advanced machine-metameric dimension analyses an industrial IoT device to sense the quality of output that matches the requirement of efficacy, efficiency, and effectiveness.

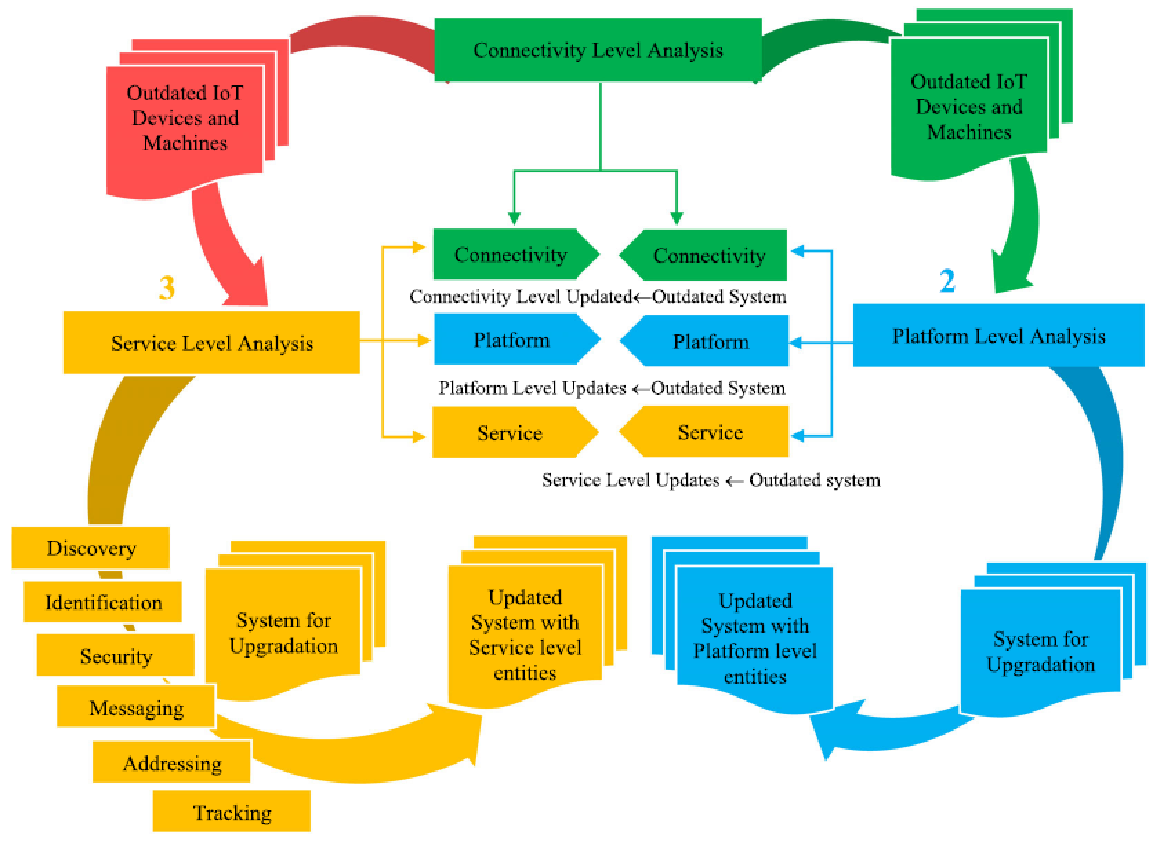

Figure 3. AmD framework for heterogeneous industrial IoT. Source: DOI: 10.1111/coin.12378

The three major constituents of intelligent objects in IoT that consume more energy are the transceiver, microcontroller, and sensor units [9]. Due to the wireless mode of communication, IoT devices are more prone to collisions. Collisions occur because of the result of several devices transmitting and retransmitting simultaneously. Thus, it results in low throughput and more energy consumption in an IoT network. Therefore, efficient collision resolution techniques should be incorporated into the IoT network. In the collision resolution technique, only one device must transmit data in a particular time slot. Thereby, reduces the collisions, retransmission overhead, and energy consumption in an IoT communicative network.

Data transmission in IoT is considered the most energy-consuming task in IoT nodes. In IoT, radio communication between the IoT devices and edge reduces the energy consumption than transmitting the data to the cloud over the cellular communication technologies. The transferring of data directly to the cloud for processing increases latency and bandwidth usage. The optimal solution is the edge computing paradigm that offloads the workload to the edge nearer to where the data is generated. Moreover, data compression techniques at the network’s edge further increase the network lifetime by reducing energy consumption.

In the physical layer, actuators, sensors, RFID tags, and BLE are power-consuming components. Various types of sensors include velocity, temperature, pressure, humidity, accelerometer, potentiometer, etc. In the network layer, routing gateways, hubs, switches, remote sensing nodes, and processing elements are power-consuming components. The application layer acts as an abstraction layer for the users to access the services of the lower layers. The application layer visualised the processed data intelligently. The application layer includes smart buildings, smart vehicles, smart homes, healthcare, smart environment, logistics, energy conservation, etc.

2.3 The role of IT in 2030 goals

The rapid evolution of ICT combined with the need for more sustainable energy consumption, expressed in the “green” policies promoted by the EU in the 2030 goals and reinforced by the NextGenerationEU Recovery Plan, has led to a shift in energy service needs. This forces electricity marketers to redesign the business model, looking for new niches in which energy efficiency serves as a common thread to make the energy transition more flexible and offer new services that provide added value to the final consumer.

Technology is key to the implementation of energy efficiency measures. Much progress has been made in recent years in terms of energy consumption measurement systems. Big Data, the Internet of Things, smart devices or demand response are tools that are accelerating the process of implementing these measures.

All this is changing the way energy is consumed and produced. On a small scale, the ability to reduce individualised consumption and stand-by periods of household appliances and machinery, or the implementation of energy management systems, have meant an advance in the energy optimisation strategies of homes and businesses. It has profoundly affected the electricity market at a global level, allowing the emergence of new roles or new types of organisation, more flexible, local and decentralised of large energy producers and distributors.

One of the new characters is that of the energy prosumer, which will occupy a key position in, for instance, the European energy system. ICT applied to efficiency boosts energy savings while facilitating self-consumption in the residential and business sectors. In this way, the final consumer’s role is changed, transforming it into an active entity of the system, capable of being an energy generator and demanding solutions that help it improve its energy behaviour decentralised.

In this way, the traditional agents of the electricity market have to adapt to this new reality, attending to three main situations: i) adjust profit margins for the commercialisation of electricity; ii) diversify the portfolio of solutions, offering new services adapted to customers to turn them into energy-efficient prosumers; iii) adaptation to a new energy scheme with multiple producers, decentralised, adapted to a local environment and close to the place of consumption, and promoting the use of renewable energies.

Digital transformation is not just about thoughtlessly incorporating the latest technology into the company. Efficient deployment involves a phase of analysis of the what and the for what, together with a cultural and organisational change and a profound change in the processes.

The digital transformation and the possibilities of Big Data, IoT, or Artificial Intelligence to convert data into valuable information offer a perfect scenario to achieve the SDGs. ICTs are crucial in that regard, as they catalyse the three pillars on which sustainable development is based: economic growth, social inclusion and environmental sustainability.

Additionally, digitalisation has the potential to enable the most vulnerable segments of society, including those living with disabilities, to access information, knowledge, and the workplace is key also when it comes to offering innovative approaches in areas such as intelligent management of water, energy consumption and waste, among others.

3 Main Barriers

3.1 Industrial integration challenges and possible solutions

Challenge: Integrating heterogeneous peripherals with low power and processing devices

Solution 1: The existing plug and play USB solution address the problem by offering a standard hardware connector, autoconfiguration, and peripheral device identification. But the USB solution is inefficient in terms of energy consumption, processing, and memory footprint. Moreover, peripherals require different chipsets, thereby increasing IoT devices’ costs in a large-scale IoT network.

Solution 2: For integrating plug and play third party embedded devices with IoT devices, manufacturers must focus on designing plug and play enabled devices. Plug and play solution incorporates protocol identification for third party devices followed by automatic driver installation for the peripheral devices. This allows the seamless integration of peripheral devices with IoT devices.

Challenge: IoT nodes rely on a single source of energy to harvest energy

Solution: Single renewable energy source to power IoT nodes is insufficient to extend a node’s battery life because of external factors such as weather conditions, day and night cycles, and vibration time lapses. In Reference 20, the author presents an energy-aware harvesting technique that integrates multiple energy sources with a node to tackle the problem.

Challenge: The actual amount of harvested energy in IoT nodes is not determined by routing algorithms

Solution: Routing algorithms fail to cope with the stochastic features of energy sources because the actual amount of harvested energy is not estimated. The best possible solution would be assessing the total energy harvested in the routing algorithm using the Kalman filter. Kalman filter adapts well with the stochastic behaviour of energy sources. In addition, the energy requirements of the node can be accurately predicted by the Kalman filter.

Challenge: Harvesting systems have a low energy conversion efficiency

Solution: The harvested energy is used to power sensors in IoT. In energy harvesting, the basic form of energy is converted into electrical energy. Therefore, efficient management systems are needed for capturing and storing power in IoT. In industrial settings, energy harvesting must be carefully done with a large waste energy supply as harvesting systems do not support greater energy conversion.

Challenge: The fluctuation in the energy status of nodes is unable to adapt with the global information of the network in a routing table

Solution: Existing routing techniques build the routing table by using the global information to forward data packets. However, global data is insufficient to adapt to the residual, harvested and energy consumption levels. Therefore, routing tables must be built by using the local information of a network to adapt to the changes in energy levels of nodes

3.2 IoT own energy consumption

Connectivity and communication devices also consume energy. Even though IoT has improved our lives greatly, IoT systems are still susceptible to various energy and interoperability constraints [10].

In the current scenario, the need for energy efficiency and interoperability among IoT products is mandatory due to the following reasons:

- IoT devices are constrained in power, memory, and network coverage. The size of objects in IoT ranges from very tiny to giant machines that are either operated on batteries or can be recharged by using renewable sources of energy. Smart IoT devices produce a massive amount of data by sensing their surrounding environment continuously. This results in the drainage of battery power within a short period.

- Because of wireless communication, IoT nodes are an easy target for intruders to launch battery drainage attacks to access the IoT network. Such type of battery drainage attacks results in node outage and network connection loss. Battery drainage attacks prevent the node from performing its routine functioning.

- IoT devices are heterogeneous due to their varying protocols, specifications, and standards. Because of the diversity in IoT components, facilitating communication among IoT devices becomes complicated. For instance, the Amazon cloud platform for IoT only supports Amazon devices for developing IoT applications to gain a market edge over their customers. Ensuring interoperability at device-to-platform, device-to-device, and app-to-app is a prerequisite for the sustainable growth of IoT.

4 Smart Applications for the Industry

4.1 Predictive maintenance

With sensors and big data exploration, it is possible to make increasingly precise predictions about costly outages of machines, motors, equipment and components. Innovative service models based on these technologies will fundamentally change the industry in the coming years. By taking a well thought out, step-by-step approach, companies can achieve significant competitive advantages even during the first phases of implementation.

Prevention is better than the cure – this adage takes on a new meaning in the digital age. Specifically, with the help of sensors and big data analyses, it becomes possible to predict damage to machines and equipment before it can lead to an outage. Called “predictive maintenance”, this approach helps to minimise business risks and operating costs over the long term. And that’s not all – using the same fundamental technology, it is also possible to monitor and systematically improve production quality, achieve almost real-time control of inventories and the supply chain, automate service activities, and create even more value through added-value services new business models [11].

As a result, investments in predictive maintenance not only bring substantial cost advantages in the maintenance of machines and production systems, they are also much more a decisive and indispensable step towards becoming an intelligent enterprise – and thus to the continuous networking and automation of the entire value chain, from sales and production to innovative after-sales services.

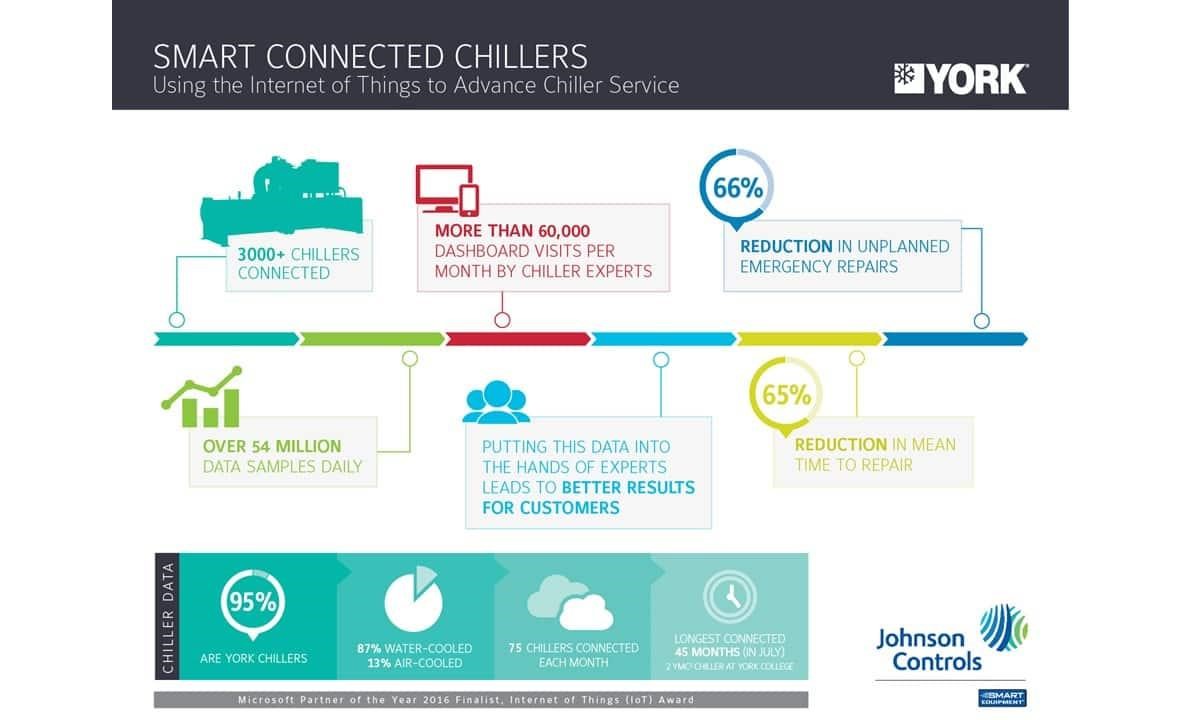

Figure 4. A successful case of smart connected chillers. Source: https://www.johnsoncontrols.com/insights/2016/buildings/features/using-the-internet-of-things-to-advance-chiller-service

To see how maintenance processes can be automated with smart products and how manufacturers, customers, and suppliers can all benefit in equal measure, consider the example of a project involving a networked water chiller. The machine was developed for industrial use, such as in factory buildings. The device is equipped with sensor technology and connected to the internet via a mobile communications module. This allows for a fleet of chillers to be managed by an IoT (Internet of Things) cloud platform, which compiles the data, delivers it to the specialised analysis systems, and automatically coordinates all servicing activities. Thanks to real-time analyses, for example, refilling the machines with fresh water can be planned precisely on a minute-to-minute basis. For this purpose, it is also possible to integrate external factors into the consumption model, such as weather data, room occupancy, and process requirements.

If a machine’s permanent status monitoring system reports a defect, the IoT platform automatically issues a service order. In this event, the technician can be there the fastest notified via his smartphone or smartwatch; the system also handles ordering the required spare parts on its own. Should more demanding repairs be necessary, the service technician can use data glasses, such as Google Glass, to view assembly instructions or to video chat with a specialist at the company’s switchboard.

Spare parts that are not quickly available from stock are manufactured on-site with a 3D printer based on digital blueprints. The technician can then conveniently record their time and expenses with a smartphone or smartwatch app while on-site or on the way home. On balance, extensive digitisation and automation accelerate the servicing process in the double-digit percentage range and significantly reduce error rates.

4.2 Automation

Low energy networking protocols are employed for industrial automation. These are considered pacesetters in the evolution of wireless communications thanks to their inherent aptitude to match radio coverage, energy efficiency, and scalability requirements for IIoT deployment. Although the modest energy consumption is one of the characteristics of low energy network protocols such as long-range wide-area networks (LoRaWAN), IPv6 over low power wireless personal area networks (6LoWPAN) and Bluetooth low energy (BLE), to name a handful, exhaustive energy operation of sensor nodes installed within a harsh environment or remote locations (e.g., in environmental and industrial monitoring use cases) makes it unfeasible for the administration of an industry 4.0 to replenish the batteries frequently. Moreover, these batteries are a consumable resource with adverse environmental effects.

To evaluate costs in an industrial environment, a LoRaWAN case study is presented in this section [12]. Being a part of the IIoT, LoRa end-devices watch several industrial parameters (such as fire detection, leakage detection, pollution monitoring, flow level monitoring, and temperature monitoring, to name a few). The results encompass several critical performance indicators (such as battery life, spreading factor support, energy consumption, battery replacement cost, damage penalty, and total cost) while appraising LoRaWAN deployed in industry 4.0.

Energy depletion can be seen as the foremost LoRaWAN parameter evaluated in the industrial environment. It serves as the primary step to assess the battery life of a LoRa monitoring node. It can be assessed as a product of the total charge consumed and the applied voltage. The maximum energy consumption value (almost 85 J per evaluated day) is when the node senses every minute. The average consumption goes on decreasing as the sensing interval is increased. For example, the average energy consumption value per day is minimum when the LoRa monitoring node senses and reports an anomaly every five minutes. It can be seen as the best-case scenario concerning longer battery life in standard LoRaWAN.

The battery replacement cost is the first cost that the industry may consider significant to increase revenue. It includes purchasing the new battery, its replacement labour cost and the cost incurred to dispose of the used batteries properly. The replacement labour cost can be variable depending upon the complexity of the spot where the LoRa monitoring node is installed. In contrast, the other two charges can be fixed by ignoring the inflation rate with time. Here, the cumulative replacement cost is considerably higher for shorter detecting intervals like 1 min. As we move from shorter to longer sensing intervals, the incremental price increases somewhat against the 5 min interval instance where the replacement cost is the minimum in a familiar industrial environment.

The damage penalty can be perceived as the second type of cost but high enough to be paid significant attention by the management of the smart industry. It refers to the cost of broken products on the production line due to an abnormal production process. The longer the measuring interval, the longer the damage interval it may originate, as smart systems can only detect irregularities to take corrective actions when they first hear the LoRa monitoring nodes after the anomaly occurrence.

The overall cost includes both types of differing costs evaluated previously; battery costs and damage penalty. Figure 5 throws light on an overall picture depicting both kinds of cost to estimate a direct contribution of each type of cost in the overall amount. To illustrate this, the damage penalty is recorded when the unit cost of production is £10, and the production rate reaches 30 products/min. Both types of costs are comparable at the start when the sensing interval is around 1 min.

It is easy to understand from Figure 5 that the overall cost increases with an intensification in sensing interval, but the ratio between both costs keeps on changing against each other.

Figure 5. Total cost summarising damage penalty and battery replacement cost

Energy gathered from renewable energy sources, available in the industrial environment, can radically play its role to develop both performance and production efficiency in industry 4.0. Here, only a few harvesting sources available in the industry are considered to demonstrate the substantial cost savings and the significant impact of the availability of this surplus energy on the industrial cost optimisation process. The following can be the three collecting sources among a thorough list of harvesting sources in conjunction with an average energy potential exploitable per day.

- Thermoelectric with a harvesting potential equivalent to 6.2 J per day for 10 h at 5°C and 5 h at 10°

- Photoelectric with an average harvestable potential of 4.3 J scavenged during eight working hours every day on 200 lx.

- RF energy with a mean potential of 1.8 J per day with 3 W power transmitted through a 5 m distant source at 9 MHz frequency

The battery life of monitoring nodes can significantly be prolonged through the presence of harvested energy. The second major benefit of harvesting energy from the industrial environment can be the tuning of sensing intervals. As a surplus amount of energy is obtainable for the monitoring nodes, they can sense and transmit recurrently to update an expert system in short intervals. It would be helpful in some industrial lines with very high unit costs of manufacture where even a minor latency in detecting an anomaly may cause a bulk of spoiled products on the faulty production line.

5 References

[1] Haq SU, Singh Y. On IoT security models: traditional and block chain. Int J Comput Sci Eng. 2018;06(03):26-31. https://doi.org/10.26438/ ijcse/v6si3.2631.

[2] Jangid A, Chauhan P. A survey and challenges in IoT Networks. Paper presented at: Proceedings of the 2019 International Conference on Intelligent Sustainable Systems (ICISS); 2019:516–521; Palladam, Tamilnadu, India. https://doi.org/10.1109/ISS1.2019.8908079

[3] https://internetofbusiness.com/fitbit-google-partnership-iot-in-healthcare/

[4] https://gliffen.com/2013/09/cultivar-raincloud-control-your-water-intelligently/

[5] https://www.iea.org/reports/global-energy-review-2021?mode=overview

[7] https://internetofthingsagenda.techtarget.com/

[8] Khan, M. A., & Abuhasel, K. A. (2020). Advanced metameric dimension framework for heterogeneous industrial internet of things. Computational Intelligence.

[9] Azar J, Makhoul A, Barhamgi M, Couturier R. An energy-efficient IoT data compression approach for edge machine learning. Futur Gener Comput Syst. 2019;96:168-175. https://doi.org/10.1016/j.future.2019.02.005.

[10] Bharti Rana, Yashwant Singh, Pradeep Kumar Singh. A systematic survey on internet of things: Energy efficiency and interoperability perspective. Trans Emerging Tel Tech. 2020; e4166. https://doi.org/10.1002/ett.4166

[11] https://www.swisscom.ch/en/business/enterprise/downloads/IoT/predictiv-maintenance-in-fuenf-schritten.html

[12] Sherazi, H. H. R., Grieco, L. A., Boggia, G., & Imran, M. A. (2020). Cost Efficiency Optimisation for Industrial Automation. Wireless Automation as an Enabler for the Next Industrial Revolution, 141-171.

To all knowledge

To all knowledge