1 Introduction to Heat Exchangers – A Detailed Study

1.1 Working Principle

In a Heat exchanger, heat flows from the hot stream to the cold one. So, the hot fluid coming out of the exchanger is a little colder, and the cold stream gets a little hotter at the exit point without mixing. That is why heat exchangers are widely used to heat up or cool down a fluid stream in a processing plant.

2 Classification

2.1 Based on Transfer Processes

Heat exchangers are classified as indirect and direct contact based on the heat transfer process.

2.1.1 Indirect Contact

In an indirect-contact heat exchanger, the fluid streams remain separate, and the heat transfers continuously through an impervious wall. Thus, there is no direct contact between thermally interacting fluids. This heat exchanger, also called a surface heat exchanger, can be further classified into direct-transfer, storage, and fluidized-bed exchangers.

2.1.2 Direct Contact

In a direct-contact exchanger, two immiscible fluids under different temperatures come into direct contact, exchange heat, and are then separated. Typical applications of a direct-contact exchanger involve a mass transfer in addition to heat transfer, such as in evaporative cooling and rectification; means this exchanger involves phase change of working fluid, which enhances the heat transfer rate, this can be further classified into Immiscible Fluid Exchangers. Gas-Liquid Exchangers, Liquid-Vapor Exchangers. Compared to indirect-contact, direct-contact heat exchangers have the following advantages:

- Very high heat transfer rates are achievable

- Exchanger construction is cheap

- Due to the absence of a heat transfer surface, the fouling problem is less

2.2 Based on Construction

2.2.1 Tubular Heat Exchangers

Tubular exchangers are widely used and manufactured in many sizes, flow arrangements, and types. They can accommodate a wide range of operating pressures and temperatures. They are used for gas-to-liquid and gas-to-gas heat transfer applications, mostly when the operating temperature or pressure is very high, or fouling is a significant problem. They are further classified as below:

- Double pipe exchanger

- Shell and tube exchanger

- Coiled Pipe exchanger

2.2.2 Plate Heat Exchanger

Plate Heat Exchangers consist of two rectangular end members holding several rectangular plates with holes in the corner for the fluids to pass through. The plates are arranged alternatively so that hot fluid flows in 1, 3 and 5 numbered plates while cold fluid flows in 2, 4 & 6 numbered plates. This arrangement lets the hot and cold fluids exchange heat while not mixing.

Each plate is separated by a gasket, which seals the plates and arranges the flow of fluids between them. The plates are either smooth or have some form of a groove. This type of exchanger is generally used for low-pressure and low-temperature applications. The plate-type heat exchanger requires less installation and maintenance space than shell and tube-type equivalent surfaces. This type of exchanger is widely used in the food industry because it can quickly be taken apart to clean.

Fig 1: Plate Heat Exchanger

2.3 Based on Flow Arrangements

Heat exchangers are classified according to the flow arrangement. The simplest heat exchanger is when the hot and cold fluids move in the same or opposite directions. This heat exchanger consists of two concentric pipes of different diameters.

2.3.1 Co-current Flow

In the Parallel/Co-current flow arrangement, the hot and cold fluids enter at the same end, flow in the same direction, and leave at the same end. The streams flow parallel to each other and in the same direction. This is less efficient than countercurrent flow but does provide more uniform wall temperatures.

2.3.2 Counter-current Flow

In the countercurrent flow arrangement, the fluids enter opposite ends, flow in opposite directions, and leave at opposite ends. The two fluids flow parallel to each other but in opposite directions. This type of flow arrangement allows the largest change in both fluids’ temperatures and is the most efficient. More heat is transferred in a counterflow arrangement than in a parallel-flow heat exchanger.

Fig 2: Flow arrangement and profile

2.3.3 Crossflow

Here, both fluids flow parallel and perpendicular to each other. In this type, efficiency lies between countercurrent flow and co-current flow exchangers. In these units, the streams flow at right angles to each other.

2.4 Based on Flow Passes

2.4.1 Single-Pass Exchangers

A heat exchanger is considered a single-pass unit if both fluids make one pass through it. Here, the fluid flows through the exchanger along its length once.

2.4.2 Multipass Exchangers

When the heat exchanger design results in either an extreme length, significantly low fluid velocities, or low effectiveness, a multi-pass heat exchanger are used, a fluid is considered to have made one pass if it flows through a section of the heat exchanger through its full length. After flowing through one full length, if the flow direction is reversed and fluid flows through an equal or different-sized section, it is considered to have made a second pass. Increasing the number of passes increases overall effectiveness and the pressure drop on the multi-pass side.

3 Types of Industrial Heat Exchangers

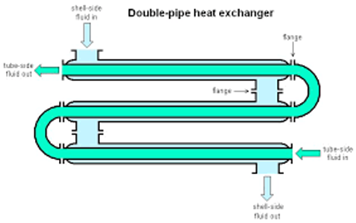

3.1 Double Pipe Exchanger

This exchanger usually consists of two concentric pipes. The inner pipe acts as the conductive barrier, where one fluid flows in the inner pipe, and the other flows in the annulus between pipes. They are also called hairpin, jacketed pipe, and jacketed U-tube exchangers. Flow in a double-pipe heat exchanger can be co-current or countercurrent. Double-pipe exchangers are generally used for small-capacity applications because they are cheap for both design and maintenance. They are simple, but they have low efficiency with the large space occupied on large scales. Therefore, many industries use more efficient heat exchangers like shells and tubes.

Fig 3: Double Pipe Heat Exchanger

3.2 Shell and Tube Exchangers

Due to their flexibility, Shell and Tube Heat Exchangers are some of the most popular exchangers. In this type, two fluids have different temperatures, one flowing through the tubes (the tube side fluid) and the other flowing outside the tubes but inside the shell (the shell side fluid). Heat is transferred from one fluid to another through the tube walls, either from the tube side to the shell side or vice versa. The fluids can be either liquids or gases. This system handles fluids at different pressures; higher pressure fluid is typically directed through tubes, and lower pressure fluid is circulated through a shell side. The major components of this exchanger are tubes (or tube bundle), shell, front-end head, rear-end head, baffles, and tube sheets.

Fig 4: Shell and Tube Heat Exchanger

3.3 Spiral Heat Exchanger

Spiral heat exchangers are generally used in chemical plants and are of circular construction. The spiral heat exchanger rolls two long metal plates around a central core to form a concentric spiral flow passage. The hot fluid flows in one channel, and just next to it, the cold fluid. This side-by-side flow is responsible for heat exchange between two fluids without mixing. The heat transfer rate associated with a spiral tube is higher than that for a straight tube. Thermal expansion is no problem, but cleaning is almost impossible. Like the plate exchanger, the spiral exchanger is compact and requires less installation and maintenance space.

Fig 5: Spiral Heat Exchanger

4 Selection Parameters for Heat Exchanger

4.1 Material of Construction

MOC for the heat exchanger depends on the types of fluids or vapours handled. It should have a definite corrosion rate. The material should exhibit strength to withstand operating temperature and pressure.

4.2 Operating Pressure & Temperature

Pressure is one of the parameters that determines the thickness of components. The higher the pressure, the higher the thickness of pressure-retaining components. Design temperature indicates whether the material can withstand operating conditions.

4.3 Flow Rates

Flow rates determine the flow area. Flow rates should be kept quite high for obtaining a higher flow area.

4.4 Flow Arrangements

Exchanger effectiveness is the main factor affected by flow arrangements, whether it is co-current or countercurrent.

4.5 Effectiveness

The heat exchanger’s thermal effectiveness is the ratio of the heat transfer rate to the maximum possible heat transfer rate.

4.6 Pressure Drop

It is an important parameter in heat exchanger design. High-pressure drop results in high pumping power, which ultimately increases the cost. On the other hand, the pressure drop also creates turbulence, which increases the heat transfer coefficient.

4.7 Fouling

The fouling of heat exchangers may be defined as the deposition of unwanted material on heat transfer surfaces, impacting its performance. Fouling increases the resistance to fluid flow and lowers the heat transfer coefficient of heat exchangers. Fouling also increases the pressure drop across heat exchangers.

4.8 Costs

The cost of a heat exchanger includes the initial price of the equipment and the installation, operational, and maintenance costs of the device lifespan. At the same time, choosing a heat exchanger that effectively fulfils the applications’ requirements is necessary.

5 Applications

- Heat exchanges are used in oil refining processes like oil cooling, steam generation, preheating, etc.

- The heat generated from the boiler can be recovered using heat exchangers

- Tubular Exchangers are used in the industrial paint system to maintain temperature.

- Plate-type exchangers are mainly used in food & chemical processing due to their ease of cleaning.

- Condensers and evaporators are used in distillation processes, refrigeration and power plants.

- Compact heat exchangers are used in aircraft & automobile industries.

6 References

1] https://en.wikipedia.org/wiki/Heat_exchanger

2] Walker, G. (1982) Industrial Heat Exchangers-A Basic Guide, Hemisphere Publishing Corporation. DOI: 10.1002/aic.690290228

3] http://www.thermopedia.com/content/832/

4] Saunders, E. A. D. (1988) Heat Exchangers “Selection, Design and Construction, Longman Scientific and Technical. DOI: 10.1016/0378-3820(89)90046-5

5] http://thepipingtalk.com/2019/11/types-of-heat-exchanger-according-to-construction/

To all knowledge

To all knowledge