Geodesic Domes: In a world of uncertain times, it is important to maintain and manage current assets, but more so, understand the reasons why your assets evolved into what they are today. Geodesic aluminium domes are one of the oil and gas industry assets that protect the product and improve emissions reduction in the aboveground storage tank (AST). They have a service life of at least half a century if maintained well.

In summary, a geodesic dome is a site-specific, structurally engineered, above-ground storage tank roof made from an aluminium structure of interlocking panels, extruded struts, gusset plates, batten bars, and hubs that require no welding.

“For the technically or mathematically minded, a geodesic dome is a spherical structure composed of triangular elements forming part of a network of circles, or ‘geodesics’, on the surface of a given sphere.” – Jonathan Glancey

1 Geodesic Domes History – Architecture

Dome roof building structures have existed for centuries. Ancient Civilizations such as the Romans applied their masonry skills and Architectural knowledge of the arch to create massive arched domes. Those concrete-style domes needed equally large supporting walls to keep the entire structure from crashing to the ground. In short, huge old domes were heavy and bound to fail at some point, and they took years to complete.

In 1926, the world’s first geodesic dome opened in Jena, Germany, as a planetarium funded by optics manufacturer Zeiss. Zeiss engineer Walter Bauersfeld conceived the project and constructed the planetarium.

In the 1950s, Buckminster Fuller was credited with popularising something futuristic like geodesic domes in the United States. Fuller titled these buildings “geodesic,” even though he neglected to cite Bauersfeld. Before designs in his patent application, Fuller was awarded a U.S. patent in 1954, although Bauersfeld designed and built his dome 26 years earlier in Germany.

Fuller took his dome design inspiration from the world around him. He was intrigued by the structure uniformity of things like snowflakes, seed pods, flowers, and crystals and determined that humans should mimic those simple, strong, and noticeably spherical arrangements [source: The Futurist Nov-Dec 1989 v23 n6 p14(5)].

The geodesic dome was appealing because it was extraordinary strength for its weight and “triangulated” surface, providing an inherently stable structure, and because a sphere encloses the greatest volume for the least surface area. He began construction on his first dome in 1948. That dome immediately failed due to the weak and thin Venetian-blind slats he used. Subsequent (and much more successful) models introduced strong, lightweight materials such as aluminium aircraft tubing. Fuller helped spread and commercialize polyhedral constructions throughout the country, which he saw as an economical, efficient way to address the post-World War II housing shortage.

His geodesic domes were partly successful thanks to a structural principle that Fuller coined – tensegrity. Fuller said, “Before meeting Kenneth Snelson, I had been ransacking the Tensegrity concepts for twenty-one years. I had used the multiple rimmed, parallel or concentric wire wheel phases of Tensegrity since 1927.” (Fuller, 1961)

Tensegrity is a word made of two others—tensional and integrity—and refers to the relationship and equilibrium between tension (Stretching force) and compression (a force that shortens or crushes something) in a structure. Unlike arches that need buttresses to prevent them from spreading due to outward forces, the modern dome uses tension to keep it from spreading.

The low quantity of materials required for geodesic domes, matched with their durability, good appearance, and ease of construction, has made them a popular choice for various structures and applications worldwide.

Figure 1 -Amundsen-Scott South Pole Station in Antarctica

In 1971, the Amundsen-Scott South Pole Station in Antarctica installed a structurally supported aluminum dome, the dome was intended to last for only 10 years, a maximum of 15 years, but in the end, was in use for about 35 years. It resisted winds of around 322 kilometres per hour and heavy snow loads. The dome was designed and built by a California company that was co-founded by Donald Richter, who learned geodesic dome design from the inventor Buckminster Fuller.

The South Pole dome was one of the first structures to use a multi-frame system, since then it has been used in thousands of domes designs around the world. It was said that it was one of the first of that kind, and that was kind of a pioneer dome. The South Pole dome was also the first to be analyzed by a computer. (Source: The Antarctic Sun, pg15, November 25, 2001)

Figure 2-© Archives de la Ville de Montréal, VM94-EX136-779

The most impressive was the eye-catching US Pavilion at Expo ‘67, the World Fair held that year in Montreal. It caught the attention of futuristic architects worldwide, especially the young architect Norman Foster, who employed Fuller as a consultant for his successful London studio until Fuller died in 1983.

Since then, it is well known that geodesic domes withstood natural disasters like hurricanes, earthquakes, and fires better than rectangle-based structures.

2 Geodesic Domes History – Bulk Liquid Storage Tanks

Aluminium dome roof Aboveground Storage Tanks (AST) are used globally today. Although it dates back almost a century, the reasons for their use of petroleum tanks evolved over the past 40 years.

The same company installed the first aluminium dome in 1968 for a water storage tank, in 1969 for a wastewater tank, and in 1977 for a petroleum tank. It was only in 1989 that API produced API 650 Annex G: “Structurally-Supported Aluminum Dome Roofs.”

The initial purpose of Aluminum Dome Roof Tanks (ADRTs) for petroleum in the US was as weather covers to keep snow and ice off the decks of external floating roofs (EFRs). Other reasons were their strength-to-span ratio and lightweight, which made it very desirable to use and retrofit existing tanks.

An example is in the early 1960s, when Colonial, a tank farm owner in the US, only had steel EFRs in its tank farms. By 1978, they had evaluated several roof replacement options and decided on ADRT with an aluminium internal floating roofs (IFRS) deck. This was adopted as the company’s standard roof design for replacements and new tanks.

By 1980, some tank owners began to cover tanks, replacing EFRs with lower-profile internal floating roofs (IFRS). This increased the working capacity, reduced emissions, reduced product vapour loss due to evaporation, and stopped the wind-induced VOCs associated with an EFR due to design. Studies proved that the ADRT was identified to improve fire safety, and over 70 per cent of large-diameter AST fires occur with EFRs. While writing this document, a fire broke out on 22 May 2020 and damaged a crude oil AST with an EFR in Hengyuan Refining Company in Berhad, Port Dickson, Malaysia.

ADRTs are structurally supported and avoid internal steel roof pillars or columns, thus avoiding column penetrations, corrosion, and coating costs associated with steel roofs. AST operators reported lower internal tank temperature with tanks fitted with geodesic domes, thus reducing product evaporation due to lower product temperature. By 1982, geodesic dome installations spread south to Brownsville, Texas. By 1985, gasoline additives and water disposal drove more conversion of EFRTs to domed EFRs or replacement of EFR with IFR altogether and retrofit it with a geodesic dome.

The API Committee on Evaporation Loss Estimation (CELE) produced the Manual of Petroleum Measurement Standards (MPMS) Chapter 19. This has emission factors for various AST configurations. Sample emission calculations in MPMS Chapter 19.2, Section 5 — using a 30,48 Meter (100-foot) -diameter EFR as a baseline — indicate emissions are reduced to 35 per cent for an IFR and 10 per cent for a domed EFR.

In 2006, API CELE research collected thermal data on geodesic domed ASTs and EFR tanks located in Dammam, Saudi Arabia, and Edmonton, Alberta. EFR tanks had slightly lower “average bulk temperature” — EFRs lose heat rapidly at night, whereas ADRTs do not, but diurnal daylight surface liquid temperature peaks. This resulted in lower overall emissions for domed EFR tanks.

API MPMS 19.4 includes thermal research information in Annex I and a table comparing superior reflective properties for mill-finish aluminium versus steel-painted white (or other colours).

In the US, the states and local jurisdictions issue air permits, and the goal is to reduce VOCs further. Considering wind reduction factors alone, before thermal benefits from high reflectivity and low emissivity of aluminium, the South Coast Air Quality District of Southern California 2001 issued SCAMD Rule 1178 to reduce emissions inventory. It states that the vapours around stored product storage tanks must be contained and regulated, and it considers the aluminium geodesic dome as the ‘perfect’ solution, thus requiring the conversion of EFR tanks to domed ASTs.

Initially, the industry covered the tanks due to snow, rain, and possible sandstorms. However, reduced vapour loss, lower product temperatures, and lower emissions are additional benefits. Lower VOCs and clean air requirements are the driving forces behind improving the ADRTs.

Overall, the geodesic dome’s genius, engineering, and design, as well as its benefits to the tank industry as a long-term asset, were timely. So now, let us dive deeper into the theory behind the Geodesic Dome.

3 Geodesic Domes Design Theory Explained

Geodesic domes incorporate the strength of a strong sphere/arch shape and are also made up of many triangles. The success of the dome as a structure is a result of the natural integrity of its shape. The dome uses the same curved shape, which gives the arch strength. The only difference is that tension is used to prevent it from spreading.

As it is well known, the triangle is the strongest shape because it has fixed angles. It is the only configuration of an artefact that is steady within itself without needing added support at the intersection points to prevent the geometry from distorting.

Arches, conversely, are three-dimensional constructs that use triangles resembling spheres to create multiple load-bearing paths from the apex centre to the point of structural support.

Pair Arches with Equilateral and Isosceles triangles and have one extremely lasting formation called the geodesic dome. Thus, if you apply pressure to one side of a triangle, that force is equally spread to the other two sides, transferring the load force to adjacent triangles. Triangles are crucial to the design strength of a dome. This distribution of the force is how geodesic domes effectively spread stress along with the entire shape.

The geodesic domes are designed with inward-tilted pentagons or hexagons in a sphere shape. The hexagon and the Pentagon can be precisely divided into triangles, so they are also inherently strong.

Dome frequency is represented by the Letter “v”, e.g. 2v is a 2-frequency, 3v is a 3-frequency dome, etc. The higher the frequency, the more triangles there are in a geodesic dome. Almost all geodesic domes are based on the Icosahedron (fig 3.) but could also be designed from other platonic solids: dodecahedron, octahedron or tetrahedron.

The Icosahedron is a geometric solid with 20 faces. Each face of the Icosahedron is made of an equilateral triangle. When the bottom of the Icosahedron is removed, it becomes a 1- 1-frequency or “1v” dome. All struts in a 1v geodesic dome are the same length, but 1v geodesic domes have several limitations in the optimal length vs strength of the struts. To design a geodesic dome with a larger area, we need to break each of the 1v triangles into smaller triangles through “tessellation”.

So here is the secret of how the lengths of the tessellated triangles cause the vertices to be pushed out into a sphere. The edges of the struts outside the tessellated triangles in higher-frequency domes are always shorter than the middle. (fig- 8)

Another reason is that each corner of the original Icosahedron triangle is part of a 5-way connection, which, if flattened, creates a 72-degree angle (Fig. 9).

The interior angles of the triangle are part of a 6-way connection, and normally, the sum of the three angles of a Euclidian or “flat” triangle creates a 180-degree angle. However, this Geodesic Dome triangle is being applied to a positive curvature of a sphere and so it must follow the rules of “spherical geometry,” which states that every triangle applied to the positive curvature of a sphere must exceed 180 degrees.

This means that the 60-degree angles in this diagram are greater than 60 degrees. These 60+ degree angles, along with the 72-degree angles in the corners, will cause the triangles to bend away from a flat plane so that the vertices will follow the curved surface of a sphere.

This combination of these 5-way and 6-way connections and their 72-degree and 60+ degree angles, along with the shorter edges on the outside of the Icosahedron triangle, will bend each Icosahedron face into a 3-dimensional curved surface to create a portion of the Geodesic Dome.

4 Geodesic Domes Cone Roof vs Geodesic Dome

Nature. Steel cone roofs and aluminium geodesic domes are engineered for maximum weather tightness, and thus, they are an ecological aspect combined with economic benefits. To prevent the stored product from being contaminated by elements of nature like snow, rainwater, sand, and other foreign matters, it was and still is today an important factor. What is the long-term benefit, and does the owner get a return on investment since this is a plant asset? Let us jump into it.

Roof Drains. Many open-top tanks with carbon steel EFRs have drainage issues with their roof drain system during the severe rainy season, hurricanes, and snow season. With the geodesic dome’s spherical shape, a drainage system is unnecessary, and the concern that your floating roof will sink into your product is dismissed.

Self-supporting clear span. Inherently, geodesic domes have an excellent strength-to-span ratio. It is self-supporting, allowing domes to span a large area without structural support columns. Over the years, the increase in the demand for storage of oil & gas products has increased the size of the storage tanks. The benefit of a clear-span self-supported aluminium geodesic dome is that it eliminates the columns required for a typical steel cone roof installation. Columns are emission risk points, and by removing them, your tanks gain emission credits from local government and international environmental agencies.

Columns and IFRs. No structural support columns mean that no columns will pass through the IFR or decks, increasing the system’s efficiency. This advanced constructional design significantly reduces evaporation loss and emissions.

Wind. As per API 2517, evaporation losses in EFRs are a function of wind speed. However, the geodesic dome prevents evaporation loss by deflecting the wind over the top, eliminating the vortex effect of wind passing over the top of an EFR. It also aids in odour control because of reduced emissions.

Loads. The dome’s design strength allows it to handle additional loads. Suspending IFRs from the dome roof increases the storage tank’s overall usable capacity. Any additional required loads, such as snow, wind, and other possible loads, are considered and calculated during the dome’s design phase. This also provides maintenance benefits.

Maintenance. Suspending IFRs from the roof allows for removing the IFR legs and determining the lowest possible point inside the tank. You can set a reasonable maintenance roof level above the floor without legs. This will ease the difficulty of accessing equipment in/out of the tank during out-of-service work.

Corrosion. Geodesic domes usually require less maintenance than a steel cone roof. It is corrosion resistant, and no corrosion dictates less debris that gets on your secondary seal system, which can create holes, causing emission leaks. No time-consuming repair process is required, such as sandblasting and painting the underside of the steel cone roof during out-of-service maintenance. Besides, the top side of the steel cone roof must be sandblasted, repaired, and coated to prevent corrosion-based damage to the roof surface.

Painting. Geodesic domes do not need to be painted for corrosion protection; a natural oxidation process occurs, creating a thin layer of protection over time. This is a huge cost-saving and adds to the return on investment (ROI) over the life of the storage tank.

Thermal Effects. The Aluminum Geodesic domes have a superior reflective property for mill-finish aluminium. They protect the stored product from UV and weather exposure, allowing for a cooler product. Covering an open-top EFR tank reduces emissions due to direct sunlight exposure, resulting in lower overall product temperature. A dome installed over an EFR can cut emissions by over 90%.

Weight. The geodesic dome is a lightweight construction. The weight of a geodesic dome is about 1/3 in weight or less compared with a self-supporting steel cone roof. For new tanks, the lightweight allows cost savings on the foundations and the tank shell. Due to the lightweight of the dome, it is also suitable for retrofitting existing tanks, which were initially designed to operate without a roof. (Fig 11)

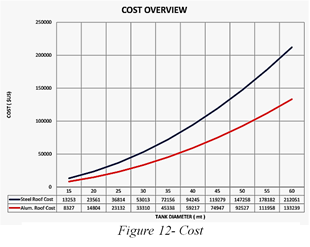

Installation. A Geodesic dome can be installed while the tanks are in service. It could be built on the ground beside the tank or even on an EFR and lifted into place with a crane. The construction of the geodesic dome does not require any hot work. It takes less time, and the customer can have the tank in service much earlier than it will take to finish a steel cone roof that needs to be welded. An example indicated that for an ADRT with IFR, a 68% lower labour requirement was needed – 6880 man-hours vs 21930 man-hours. Installation was done approximately 40% of the time with a lower-skilled labour team. (Fig. 12)

Pressure. Unless the customer specifies a different request, the Internal design pressure shall not exceed the roof’s weight. The internal pressure of ADRTs is limited per API 650 G.4.3 to 9″ of water. Testing has been performed to 26″ of water, and petroleum applications are in service to 17″ of water. The ability to contain pressure is specific to the design and manufacturer.

Gasket compatibility. A critical aspect that geodesic domes must consider is the gasket compatibility with the product stored in a storage tank when NO floating roof is used.

Lightning. EFR tanks could accumulate potential charges due to steel-to-steel contact and be a potential ignition source upon lightning strikes. It is the opinion of many manufacturers that the Aluminum Dome roof does serve to provide the Faraday Cage Effect, even though that metallic shell is very thin. If no combustible vapours are present in the atmosphere due to emissions, there should be little to no concern with lightning. There should be no reason to additionally protect a dome-covered internal floating roof from exposure to lightning, as the Faraday Cage has proven effective. Still, bonding IS required per API 650-H for other purposes. Aluminum does not hold a static charge and will not spark; it will dissipate atmospheric discharge.

The original objective of aluminium geodesic domes covering tanks remains an efficient, cost-effective means of reducing maintenance and operating costs. Still, recent motivation and market drivers are to reduce further the emissions of VOCs associated with petroleum storage tanks.

There are plenty of manufacturers worldwide, and each has its unique propriety design features and specific benefits for the customer. As such, customers should take a structured approach to ensure they select the correct Geodesic Dome that provides the best value for the application.

A small evaluation has been made between manufacturers in the market, highlighting the features and benefits required to decide. You could make your bid evaluation much easier by evaluating these components, asking the right questions, and factoring in the variance.

The main components important to mention for evaluations are the beam, batten bars, nodes, support structures, and accessories available.

5 Geodesic Domes Technological Factors

Beams and Batten bars design (Fig 14 – Fig 18)

- The batten bar/gasket system should fully encapsulate panel edges to ensure a perfect seal to prevent emissions.

- The beams are designed with an extruded groove to receive fasteners, which prevents batten fasteners from penetrating through and into the dome’s interior. This groove’s specific design ensures that the fastener can be turned in and out into the same position several times.

- Gasketed stainless steel batten fasteners provide extra security for a water-tight connection.

- Single web beam profiles reduce the structure’s weight without compromising structural performance.

- Double web beams allow for a heavier load-bearing ability, greater unsupported clear span, and possible lower profiling. The extruded box beam prevents buckling failure compared with I-Beams with less material.

- The required strength to carry the design loads and the weight-to-strength ratio must be considered. This results in different levels of material efficiencies and will impact the cost.

- The typical and most popular dome height is about 16% of the tank’s diameter. A low-profile dome is usually requested when there is a height restriction in the area, typically close to airports. Lower-profile domes are more expensive.

- The panels lock mechanically in place securely, incorporating a seal with a fully engaged gasket. The mechanical sealing is either done by ridges located on the top flange engaging with sheeting or by torsional buckling requirements adopted by the Aluminum Design Manual and International Building Code (IBC 2012). These design features are the key to providing effective water—and gas-tight domes.

- The mechanical seal’s feature also protects the gasket from product-side attack to prevent premature gasket failure.

- A low-profile or Flush Batten design seals increase water shedding and eliminates ponding. A flush batten system eliminates ponding that could occur even on a low-profile design while providing a water-tight cover solution.

- Unique designs have the gasket fully enclosed, non-exposed, and protected by the batten against ultra-violet exposure and seal degradation.

- Silicone is an inert material that is not affected by UV. Solid Silicone gaskets are the preferred gasket material for sealing the nodes and batten bars. Silicone gaskets can last 25-30 years.

- The exclusion in the integral tension ring will result in a lower-cost dome, but the buyer will still need to install a steel tension ring on the tank shell and will still be exposed to additional costs. It is easier to retrofit an existing tank with a Geodesic Dome that includes an integral tension ring, which, in turn, can save on installation costs. For new tank projects, for vapour-tight domes, a fixed-type dome with a tension ring installed on the tank shell will provide an improved gas-tight design.

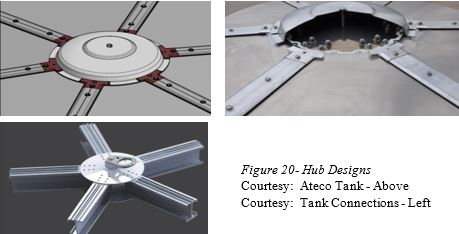

The Node

The Node is where the beams and plates meet and are connected to upper and lower flanges to resist transverse deflection. These nodes need to be water—and gas-tight and are thus fitted with hubs with gasket sealing that allows for tight sealing and reduces emissions. In a well-designed, manufactured, and installed dome, the top of the panels and battens are flush, which fixes the main dome leak risk point: the hubs.

The hub design must allow easy cover removal for inspection and adjustment of internal floating roof support chains when fitted.

Support Connection Details

Depending on the application, the dome could be free-ventilated or vapour-tight (fig. 21 & 22). A free-vent eve will be good enough for a standard water tank, but when you dome a petrochemical tank and need to reduce emissions, a vapour-tight design could be requested. A vapour-tight ADR is more expensive due to larger load requirements and will increase material use.

The dome is also designed with either a sliding or a fixed support connection where the beam and the tank wall meet each other. (Fig. 21-23)

Accessories. The ADR is shop fabricated, and to reduce installation time and additional cost, the complete list of additional accessories required on the ADR is included. This ensures that panes and accessories fit each other perfectly, and now, additional cutting and drilling onsite are required.

A list of accessories could include

- PV Vents

- Emergency vent

- Centre Free Vent

- Triangular skylight

- Gauge hatch

- Manhole cover

- Door Section

- Nozzles

- Centre Safety line support

- Eyebolt at the apex

- Connectors for IFR Cables

- 24” Flame detector Flange

- Crane Lifting lugs

- Radial walkways

- Rolling ladder connections,

- Sprinkler support systems

6 Geodesic Domes Construction and Lifting Methods

Construction. The benefit of the Geodesic Dome is that it requires no hot work and is pre-manufactured and shipped to the site in parts where it only requires assembly. The Dome could be assembled INSIDE the tank, directly “In-Place” on the shell support structure of the tank or NEXT TO the tank. The latter method is preferred when the tank is kept in service while the dome is assembled and installed on the tank. A typical application where the tank is kept in service during construction is for a wastewater tank.

There are two methods of construction: one is from the centre cone/hub outwards (Fig 25), and the second is from the outside to the centre (Fig 24). Usually, domes will be erected” in Place” directly on the support structure when there are space constraints. The “In-Place” construction consists of a dome built directly on a tank shell from outside towards the centre.

When the Dome is assembled inside or next to the tank on the ground, the erection process uses tripods or quadpods to lift the dome at each tier. This makes it convenient and safe to work at grade and limits the work at heights. After the dome is constructed, it could be raised to the top of the support structure using winches or cranes. This method ensures a safer, quicker installation process.

Lifting. The dome lifting method will affect installation time and equipment cost (e.g., crane vs. grip hoist). The method that would be possible needs to be clarified in the beginning since it affects the timeline and the cost of the project.

When the Dome is assembled on the floor inside the tank, rigging will be required to fit it on the support structure. This lifting could be done utilizing two methods: grip hoist winches and pulleys (Fig. 27) and cranes for rigging (Figs. 26 and 28).

A crane is the least effective alternative. However, in certain situations, cranes are required when they are available. However, contingent factors such as light wind conditions cause the lightweight dome to sway too much to allow for a safe installation. In Fig. 26 below, four Cranes were used to lift this dome into place from inside the tank.

Once the assembly process of constructing the dome inside the tank has been completed, the erection crew utilizes a system of grip hoist winches and pulleys to hoist it to the top of the shell efficiently. It requires several Grip Hoists (fig. 27) fitted around the top of the tank’s shell so the dome can be lifted in place.

Once the assembly process of constructing the dome inside the tank has been completed, the erection crew utilizes a system of grip hoist winches and pulleys to hoist it to the top of the shell efficiently. It requires several Grip Hoists (fig. 27) fitted around the top of the tank’s shell so the dome can be lifted in place.

The Crane Erection process consists of assembling a dome on the ground next to the tank and then lifting it into place with a crane. This allows the tank and the dome to be constructed simultaneously and saves valuable time.

The initial cost for a Steel Cone Roof is less than that of an Aluminium Dome Roof, but the cost savings could be realized over the lifetime of the dome due to lower maintenance costs. The increased steel prices and high labour costs make the Aluminium dome roof more attractive. Overall, the dome is more cost-effective in its life cycle compared to the life cycle of a steel cone roof.

About EPCM

7 Bibliography

Apex Dome by Tank Connections Retrieved 5 21, 2020, from

https://www.tankconnection.com/assets/pdf/Apex_Domes_web.pdf

Ateco dome roof Catalog Retrieved 5 21, 2020, from

https://drive.google.com/file/d/1f4CAm-HyXiL3ywEomvtTceSp_D7K64c0/view

Buckminster Fuller’s 50-foot “Fly’s Eye” Retrieved 5 21, 2020, from archpaper.com

Buckminster Fuller’s 50-foot “Fly’s Eye” is coming to Crystal Bridges

CST Optidome Retrieved 5 21, 2020, from

Environmental Regulations Drive Changes In Floating-Roof Designs for Storage Tanks – Retrieved 5 21, 2020, from

https://www.bulktransporter.com/regulations/article/21654159/environmental-regulations-drive-changes-in-floatingroof-designs-for-storage-tanks

Fuller, B. (1961). Tensegrity. Portfolio and Art News Annual(4), 112–127, 144, 148. Retrieved 5 21, 2020, from http://www.rwgrayprojects.com/rbfnotes/fpapers/tensegrity/tenseg01.html

Geodesic Dome. (n.d.). Retrieved 5 21, 2020, from Wikipedia: The Free Encyclopedia: http://en.wikipedia.org/wiki/Geodesic_dome

Geodesic Domes and Charts of the Heavens. (n.d.). Retrieved 5 21, 2020, from Telacommunications.com: http://www.telacommunications.com/geodome.htm

Buckminster Fuller. (n.d.). Retrieved 5 21, 2020, from Wikipedia: The Free Encyclopedia: http://en.wikipedia.org/wiki/Buckminster_Fuller

Superior Dome. (n.d.). Retrieved 5 21, 2020, from Webb.nmu.edu: http://webb.nmu.edu/SportsAthletics/SiteSections/Facilities/SuperiorDome.shtml

What is Geodesic Dome Frequency? An Explanation. Retrieved 5 21, 2020, from ziptiedomes.com

https://www.ziptiedomes.com/faq/What-Is-Geodesic-Dome-Frequency-Explained.htm

To all knowledge

To all knowledge