1 Introduction to Fuel Gas Booster Skid Systems

Fuel Gas Booster Skid Systems: When a gas engine or gas turbine requires a pressure above the available pipeline pressure, a fuel gas booster is desired. The fuel gas booster (gas booster) compressor provides gaseous fuel (natural gas, biogas, or similar) to a gas turbine or piston-type engine at high pressure. The engine operates best with a steady supply of fuel gas at a constant pressure. The gas booster provides a steady supply of fuel gas at a constant pressure by using two tanks and a back pressure control valve (also called a back pressure regulator). A fuel gas boosting compressor is the “blood pump” for gas turbine power plants because of the fuel gas booster supply steady gas to the gas turbine power plant. Figure 1 shows a typical fuel gas booster unit for industrial applications.

Fig 1: A typical fuel gas booster unit (Image Source: Corken Inc.).

2 Applications of Gas Booster Skid Systems

Gas booster compressors are crucial for reliable gas turbine power plant operations. The demand for fuel gas booster has been increasing because gas turbines require higher fuel gas pressures to achieve increased performance efficiency and because pipeline pressures fluctuate due to increased overall and peak demand requirements. The gas turbine requires a certain pressure during the combustion of the fuel gas and pressurized air. When the main pipelines gas pressure is inadequate, the gas booster compressors are installed. The required gas pressure for conventional types of industrial gas turbines is around 230 to 330 pounds per square inch gauge (psi), or 16 to 23barG on average. However, the latest industrial gas turbines require relatively high-pressure fuel gas, such as 500 to 600 pis (35 to 42 bar). Besides, aero-derivative type gas turbines now require gas pressure as high as 700 to 1,000 psi (49 to 70 bar).

At the same time, natural gas demand has been increasing so that the new supply of natural gas are not sufficient for the growth of demand in many parts of the world. As a result, the gas pressure in the pipeline cannot be maintained as high as required. This is particularly true during peak demand, such as summertime or daytime. It means that the gas pressure in the pipeline would gradually decrease and even fluctuate. A fuel gas booster unit correctly handles such fluctuations of gas pressure from the pipeline while simultaneously meeting the gas turbine’s required gas flow rate. Two changeable conditions are most relevant to fuel gas boosters: the inlet gas pressure fluctuations and the turbine’s load changes. Besides, reduced oil carryover and low pulsation/vibration are also important, because they can lead to mechanical problems. The gas turbine combustors are very sensitive to pulsation. Thus, pulsation is a big concern to gas turbines with dry low NOX combustors. Natural gas can include impurities or dirt, and its precise composition can even be subject to change.

The gas booster system is used in many sectors, especially for industrial applications. However, the gas booster system can also be used for the following applications-

- Leak detection of pressure components

- Low-pressure gas retrieve from storage bottles

- Gas charging accumulators

- Pressurizing gas cylinders and shock absorbers

- Breathing air systems for scuba and fire department SCBA tanks

- Boosting gas pressures from nitrogen and oxygen generators

- Gas assist injection moulding

- Boosting gas pressures from the vaporized liquid source

- Natural gas compression

- Natural gas compressor skids

- CNG loading stations

- CNG storage tanks

- Tanker truck loading/unloading

- Railcar loading/unloading

- Fuel gas boosting

- Liquefied gas transfer

- Gas gathering

3 Flow Diagram of a Standard Gas Booster and How it Works

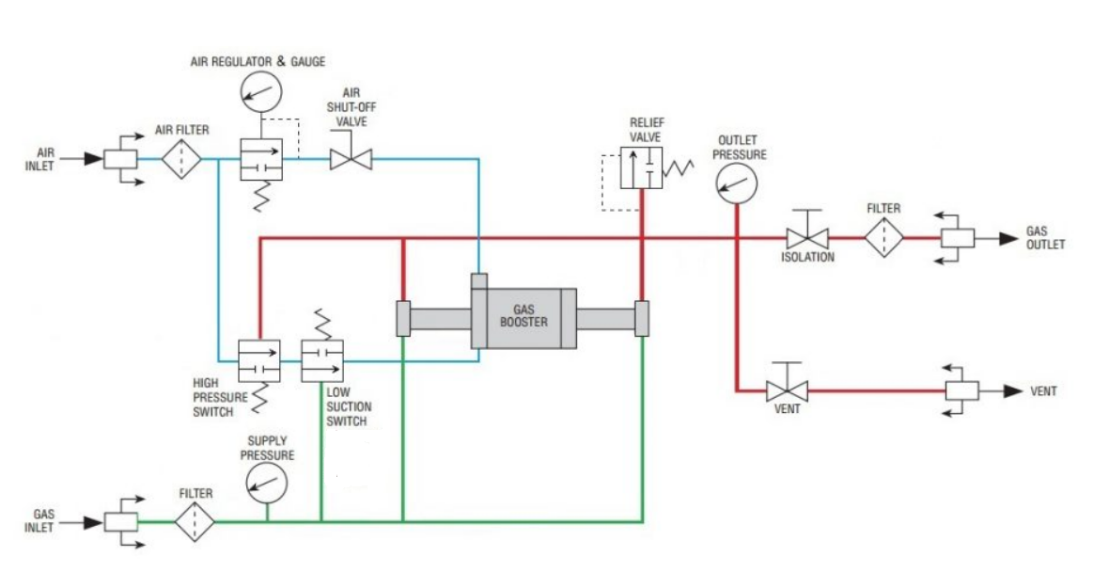

Figure 2 shows a schematic of a gas booster skid. The gas passes through the air filter and goes to the inlet of the gas booster. The supply pressure is measured by using a pressure gauge. Several pneumatic valves are being controlled by compressed air. Fuel gas boosters are usually piston or plunger type compressors. A single-acting, single-stage booster is the simplest configuration. It comprises a cylinder and a piston, designed to withstand the operating pressures. The piston is driven back and forth inside the cylinder. The cylinder head is fitted with inlet and outlet ports. Each inlet and outlet pipes or hoses are connected with a non-return valve, constraining flow in one direction from supply to discharge. When the booster is inactive, and the piston is stationary, gas will flow from the inlet pipe, through the inlet valve into the space between the cylinder head and the piston. If the pressure in the outlet pipe is lower, it will then flow out and to whatever the outlet pipe is connected to. This flow will stop when the pressure is equalized, taking valve opening pressures into account. This system is called the gas purging system of a compressor.

Fig 2: Flow schematic of a gas booster unit.

When the booster is started, the piston withdraws along with the cylinder, increasing the volume between the cylinder head and the piston head. As a result, vacuum pressure will be developed, and gas will flow in from the inlet port. On the return stroke, the piston moves toward the cylinder head, decreasing the volume of the space and compressing the gas. When the pressure is sufficient to overcome the pressure in the outlet line and the opening pressure of the outlet valve, the gas will flow out of the cylinder. This cycle starts over again and continues during the operation of the unit. Depending on the required pressure for the operation of the industrial equipment, there may have multiple stages of compression fo the fuel gas booster compressors. In a multi-stage fuel gas booster compressor model with a compression ratio > 5, the outlet of the fuel gas is cooled by an intercooler for cooling.

4 Fuel Gas Booster Skid Systems: The Main Components of the Gas Booster Unit

A gas booster work on the principle of a pressure intensifier. They are used to compress gases and compressed air to higher pressures and are operated with a driving pressure of up to 10 bar of compressed air. The driving pressure is required to compress the respective fluid to a higher operating pressure. The transmission ratio is calculated from the piston area of the large air piston to that of the smaller size high-pressure piston. Depending on the booster type, the primary pressure should be selected. The main components of a single-stage gas booster compressor assembly are described as followings-

4.1 Pilot valve

The pilot valves are used to enable the air piston to move the stop positions over. The pilot valves are actuated in the stop positions by the air piston and transmit air pulses to the spool valve. This enables the pilot valves to air out and vent the actuator chamber of the spool valve, which moves the spool valve from one stop position to the other.

4.2 Spool valve

The purpose of the spool valve is to use compressed air alternately to the top and bottom of the air piston. The spool valve is controlled by using the pilot valves and make sure that the drive air reaches the opposite side of the air piston.

4.3 Drive unit

To take up the drive air (compressed air) and actuate the high-pressure booster piston via a piston rod the drive unit is used. Therefore, the fuel gas is compressed to a higher pressure. The pressurized fuel gas is supplied to the gas turbine unit.

4.4 Gas booster with inlet and outlet valve

The fuel gas booster locks the compression chamber and separates this spatially from the ambient pressure. The gas booster contains the inlet and outlet valves for the intake and exhaust of the gas in the system. The gas to be compressed enters and exits the booster compression chamber through these inlet and outlet valves.

4.5 High-pressure unit

For a single-stage booster high-pressure unit, it consists of the pressure cylinder, a gas booster with inlet and outlet valves, and the high-pressure piston with seal and guide elements. The unit is used to compress the respective gas. There are lubrication systems for the smooth run of the piston inside the cylinder.

4.6 Exhaust air silencer

The exhaust silencer serves to reduce noise when expanding drive fluid which is discharged from the booster. On completion of its task, the drive fluid exits the booster via the exhaust silencer. The exhaust air silencer may be made of plastic or aluminium, depending on the booster model.

4.7 Cooling cylinder

The cooling cylinder serves to insulate and cool the high-pressure booster unit. The cooling cylinder encloses the high-pressure cylinder. The expanding (very cold) drive air is routed into the space between the two cylinders to cool the high-pressure cylinder during operation. For a packaged compressor systems may include the followings-

- Lubricated and oil-free reciprocating

- Side-channel pumps

- Sliding vane pumps

- Engine-generator sets

5 Different Types of Gas Booster Systems

Depending on the compression ratio required, single or two-stage compressors can be used in the system. The single-stage compressors are typically used for compression ratios of 5:1 or less. The two-stage compressors are required for higher compression (typically at 5:1 compression ratio). Water-cooled or Air-cooled intercoolers and aftercoolers can be used depending on the availability of cooling water at the site and size of the compressor. A pulsation system is used in the fuel gas skid for the regulators and the gas meters because gas booster compressors work best with minimal gas pulsations. Tank storage is recommended as the tanks protect these pulsation-sensitive components by dampening pulsations generated by the fuel gas compressor. Selecting the correct type of fuel gas compressor is one of the most critical factors in achieving a successful plant operation. There are different configurations of the gas booster compressors-

5.1 Single-acting single-stage

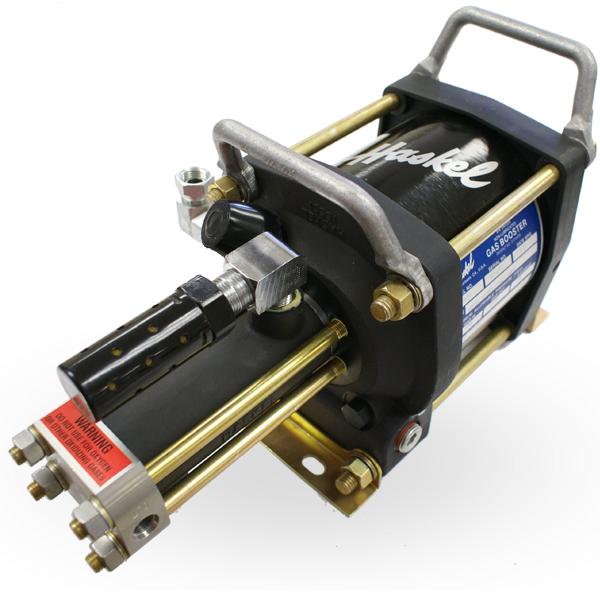

A single-acting, single-stage booster is the simplest configuration of the gas booster unit. It comprises a cylinder, designed to withstand the operating pressures, with a piston which is driven back and forth inside the cylinder. The cylinder head is fitted with inlet and outlet points, to which the supply and discharge pipes are connected, with a non-return valve on each, constraining flow in one direction from supply to discharge. Single acting-single stage gas boosters are the smallest and lightest with pressure capabilities up to 39,000 psi (2690 bar). Single acting-single stage gas booster provides economical means of boosting pressure for testing of small components and similar applications where volume is small, and efficiency is not important. Figure 3 shows a typical single-acting single-stage gas booster compressor.

Fig 3: Single-acting single-stage gas booster compressor (Image Source: Haskel)

5.2 Double-acting single-stage

Double-acting single-stage gas booster pumps twice the volume of a single acting-single stage booster per cycle. It requires less air drive since the inlet gas pressure is assisting the air drive in each direction, providing a substantial portion of the required driving force. A double-acting single-stage gas booster compressor is very efficient for boosting the large volumes of gas at low to medium compression ratios. The applications of the double-acting single-stage gas boosters are in high-pressure gas testing or process testing, charging of accumulators, boosting the gas pressures from nitrogen or oxygen bottles and generators, leak detection system, nitrogen injection for moulding machines, pressure autoclaving, etc. Figure 4 shows a typical double-acting single-stage gas booster compressor.

Fig 4: Double-acting single-stage gas booster compressor.

5.3 Double-acting two-stage triple air-head

In a double-acting two-stage triple air-head booster compressor, there are two cylinders, which operate alternately, each pressurizing gas while the other is refilling. In the second stage, there is a smaller bore and is filled by the gas-pressurized by the first stage, and it pressurizes the gas further. The stages operate in series, and the gas passes through both of them in turn. Figure 5 shows a typical double-acting two-stage Tripple air-head gas booster compressor.

Fig 5: Double-acting two-stage triple air-head gas booster compressor (Image source: High-Pressure Technologies LLC.)

6 Comparison Between Single-Stage and Double-Stage Gas Booster of Fuel Gas Booster Skid Systems

The main difference between single- and two-stage gas booster is the number of times that gas gets compressed between the inlet valve and the tool nozzle. In a single-stage gas booster, the gas is compressed one time; in a two-stage gas booster, the gas is compressed twice for double the pressure. Single-stage gas boosters are also known as piston type gas booster. The processes that take place within a single-stage gas booster:

Gas is passed into a cylinder.

The trapped gas is compressed in a single stroke with a piston at roughly up to a certain pressure.

The compressed gas is delivered onward to the service line

The process within a two-stage gas booster is similar to that of a single-stage, but with one variation: the compressed gas isn’t sent to the service line directly. It is instead sent to the intercooler and cooled. This intercooler decreases the compressor work, and at the second stage of compression, more high pressure is attained at a low work input. Therefore, the high pressurized gas is delivered to the service line for different purposes such as power plants on industrial applications.

The relative quietness of the single-acting single-stage gas booster compressor makes them ideal for smaller working environments. Because it has only one cylinder, therefore, only one piston stroke for each revolution of pressurized gas, on the other hand, the two-stage gas booster is ideal for high pressure boosting and larger industrial applications. The choice between a one-stage or multi-stage gas booster compressor should be based on the size and nature of your operations. In summary, one stage units are for small-scale projects application, while two-stage models are more geared toward industrial-scale arsenals.

Two-stage gas booster compressors are more expensive than the single-stage counterparts because there are more parts involved. However, the parts in a two-stage unit typically require maintenance at less frequent intervals. In the long-run, the costs to operate a two-stage compressor could be less expensive. A two-stage gas booster compressor can also make your operations less expensive if your applications are industrial scale. In a power plant, a single-stage compressor wouldn’t likely suffice. You would probably need a second single-stage gas booster compressor to attain high pressure, thus raising the operating costs. For industry use, the upfront investment in a multi-stage gas booster compressor could save money over time.

7 Gas Booster Selection

Gas booster selection involves the calculation of the gas pressure lift required for operation and the gas volume flow rate. The gas flow rate can be calculated by dividing the burner firing rate by the calorific value of fuel gas. In situations where a single gas booster is supplying several burners, selection involves calculating the total gas flow of all the appliances and the maximum gas supply pressure required by any single appliance. The ability of the booster to increase pressure is a function of the driving pressure, multiplied by the nominal booster ratio. Within each booster model, there are standard materials of construction.

It is also crucial to note that all pipework should be sized as normal, irrespective of whether a booster is being used, aiming for just a 1 bar pressure drop between the gas supply meter and the appliance. The installation of a gas booster is not a way to enable the use of smaller gas pipework. The use of a gas booster will not overcome any existing issues with the undersized piping design. When installing the gas booster, it may be necessary to provide information about the ramp profile to the gas supplier. It will be helpful to ensure the pipework upstream of the meter for the correct value. The ramp profile is not governed by the booster but by the burner/boiler or other appliance that is consuming the gas for smooth industrial operation.

The life cycle of a gas booster is also important during the selection of the gas booster unit. The life cycle of the system will vary depending on several parameters such as the use of the booster unit, what it is being used for, how hard it is used, and the schedule maintenance practices. There are standard life cycle expectations with the caution that everything is dependent on how well you take care of the machines in the system. The cost-effectiveness ultimately depends on the use, life cycle, maintenance costs, and rate of depreciation. The overall cost-effectiveness of the system is an integral part of identifying the budget ahead of time and to consider selecting the appropriate system.

8 Fuel Gas Booster Skid Systems: Industry Standards for Gas Booster Skid Systems

Gas booster skid installation and operation may have different standards based on the location, size, and type of the gas booster unit. All the parties related to the gas booster skid unit such as the owner of the gas booster skid unit, operation and maintenance (O&M) company, engineering procurement and construction (EPC) company, and also the manufacture of the unit need to follow the local and international safety and standard guidelines lines. Here are some industry standards for the gas booster skid-

- Pipe fabrication to ASME B31.1 and B31.1 standard;

- Structural steel designed to AWS standards;

- Pressure vessel ASME standards;

- SolidWorks 3D modelling;

- AutoCAD Mechanical & Electrical design

9 Gas Booster Skid Systems Design Process

For an industrial-grade gas booster skid design system, the designer needs to design an incoming and outgoing piping system, compressed air supply system for pneumatic valve control system, gas booster control system, gas treatment system, unit basement civil construction system, gas compression system, and so an. No matter what the required size and specification, the entire system need high precision engineering comprehensive design process for completely tailored, highly reliable operation conditions. The methodology involved close collaboration of mechanical engineering, control engineering, civil engineering, and instrumentation engineering works. The first step of the design process involves a client consultation with speciation to understand the system requirements and formulate an ideal design.

As a second step, after the consultation about the clients’ requirements with the design engineers, the experienced team can determine the required characteristics of the gas booster skid. The design engineers find out the necessary operational characteristics, such as specific fluid properties, flow rate, temperature, pressure, and so on. As the third stage, the safety engineers determine the safety features that need to be included in the design, as in some cases the system will be handling materials that pose hazards, such as natural gas or certain types of chemicals. Therefore, the final design comes with the required standard size of pumps, coolers, compressors, motors, heat exchangers, control systems, control valves, enclosure for the specific location weather conditions, etc. The design might be submitted with the list of required major equipment for client approval and addresses any input or feedback they may have. Once the customer signs off, the design process moves onto creating the piping and instrumentation diagram (P&ID). When creating a PI&D, the layout indicates the entire process flow for the system, from skid inlet to outlet. At this point, there should have established specific requirements and features of the skid and identify needed valves, drains, piping sizes, and connection points. In addition to working on skid system design, the implementation of the design of the control system, and the locations of control valves and sensors for pressure, temperature, and flow are decided.

After designing an original diagram that noticeably depicts all necessary information for the skid systems and other equipment, the design team meets with the customer to make sure the design meets all their unique requirements. Once the design team gets the customer’s approval at this stage, the team uses the P&ID to make a complete, highly detailed 3D model of the system. The model allows the customer to identify specific details, including the precise inlet/outlet locations, overall dimensions, weight, and structural steel base anchor points. Often the design team runs stress and vibration simulations to analyze the system further and ensure optimal performance and reliability.

The presentation of the gas booster skid drawings and 3D model files allows the client to see how the system will integrate with existing equipment, and illuminate essential details, such as component materials, connection types, clearances around major components for maintenance purposes, and the electrical or control panel locations. With the 3D model in hand, the customer can provide additional input, and any required changes can be made before the actual construction process begins.

10 Gas Booster Skid Systems Construction Process

After approval of the design of the gas booster skid by the customer, the construction steps are initiated. By keeping customers involved at every stage of the design process, cost and time can be saved at a significant level, and it improves the system performance and reliability. The active participation of the client and the construction team errors and inefficiencies are eliminated at an early stage. The construction phase starts at the manufacturer construction yard. It may be required high capacity overhead cranes, painting facilities, welding equipment, and fabrication machinery. The bases and structural steel can be fabricated manufacturer inhouse of outsourcing facilities. The manufacturer completed the instrumental and control system testing at manufacturers entity testing laboratories. The manufacturers’ in-house fabrication of pressure vessels, platforms/supports, structural bases allows the custom components in less time and while saving costs. Besides those testing and construction works, the construction site needs to be prepared. The civil works for the basement of the gas booster skid need to be done by following the local and international standards. It may be required permission from local authorizes. Additional paper works for safety, and the environmental issues need to be completed in due time.

During the mechanical installation work phase, the piping, testing, and pre-commissioning of mechanical equipment works need to be done. The fuel gas booster skid installation works need to be accomplished in concurrence with the manufacturer’s instructions, standard industrial practices, and relevant codes and standards. The electrical/instrumentation installation work is usually identified in a separate document. The electrical/ instrumentation work shall be coordinated with the mechanical work to provide a complete, safe, and reliable system. Finally, the manufacture usually performs a test run as per the manual and guidelines to ensure the performance, safety, and reliability of the system.

About EPCM

To all knowledge

To all knowledge