By Dr DF Duvenhage

Introduction

The mining sector, integral to the global economy, produces substantial quantities of waste byproducts during the extraction and processing of valuable minerals. Among these byproducts, mine tailings represent a significant challenge, requiring comprehensive strategies to mitigate environmental impacts and ensure the safety of nearby communities. Tailings storage facilities (TSFs) are pivotal in addressing these challenges. TSFs are a cornerstone of responsible mining operations. They ensure that waste materials generated by these processes are managed to minimize environmental risks and align with sustainable practices. This article extensively explores TSFs, focusing on their global importance, engineering complexities, and contextual relevance to South Africa’s mining industry.

Mine tailings are the residual materials generated after the economically valuable components of ore have been extracted. These materials typically consist of finely milled rock particles, process water, and residual chemicals from extraction and separation procedures. The specific composition of tailings is contingent upon the mineralogical characteristics of the ore body, the processing technologies employed, and the nature of the mining operation. Due to their potentially hazardous properties, mine tailings necessitate stringent containment and management to prevent environmental contamination and adverse health impacts on human and ecological systems.

TSFs are engineered systems designed to contain tailings securely. Unlike conventional water dams, TSFs are dynamic structures that evolve over a mining project’s lifecycle to accommodate increasing waste volumes. Typically constructed from on-site earth and rock waste, these facilities include embankments designed to stabilize and isolate tailings materials, thus mitigating the risks associated with seepage and structural failure.

Key roles of TSFs include:

- Environmental Safeguarding: Preventing the migration of hazardous substances into surrounding ecosystems.

- Water Recirculation: Enabling the recovery and reuse of process water to reduce the operational water footprint.

- Risk Management: Ensuring structural integrity to avert catastrophic failures that could result in environmental disasters and societal harm.

Many factors, including local topography, climatic conditions, and the geotechnical properties of the ore influence the methodologies employed in managing and storing tailings. Prominent techniques include:

- Conventional Slurry Storage: This method involves depositing slurry tailings hydraulically into embankment-enclosed impoundments. Regular maintenance and monitoring are essential to control seepage and uphold structural stability.

- Dry-Stack Tailings: In this approach, tailings are dewatered to a semi-solid state, allowing for compaction and storage in stable, dry stacks. This method substantially reduces water consumption and the risk of dam failures.

- In-Pit Storage: Utilizing decommissioned open-pit mines for tailings disposal minimizes the need for new containment infrastructure and reduces land-use impacts.

- Backfilling: Tailings are repurposed to backfill underground mine voids, aiding in ground stabilization and minimizing surface storage requirements.

The governance of TSFs demands adherence to rigorous international standards and regulatory frameworks to avert disasters such as dam collapses, which have historically caused extensive environmental damage and loss of life. High-profile incidents, including the Brumadinho disaster in Brazil, underscore the necessity of adopting innovative and robust tailings management practices globally.

South Africa, renowned for its vast mineral wealth and extensive mining history, presents a distinctive context for TSF management. The country’s mining activities, particularly in gold and platinum production, generate immense quantities of tailings. The management of these tailings pose significant challenges within the South African context. As a water-scarce nation, South Africa prioritizes water recovery within TSFs, integrating advanced technologies to maximize reuse and minimize waste. The design of TSFs must account for the potential impact of seismic events, however rare they may be in South Africa, necessitating advanced geotechnical engineering solutions to ensure long-term stability. Historical mining operations have left a legacy of abandoned TSFs, many of which pose ongoing environmental risks near urban areas. Re-mining these facilities for residual valuable minerals offers an opportunity to mitigate these risks while recovering economic resources.

The South African regulatory framework is committed to improving TSF management through stringent safety standards, enhanced transparency, and active community engagement. Collaborative efforts between government bodies, mining companies, and academic institutions have driven innovations in tailings management and set benchmarks for sustainable practices in the region.

Tailings storage facilities represent a critical intersection of engineering, environmental science, and sustainable resource management within the mining industry. Globally, their role extends beyond mere containment, addressing broader objectives of environmental stewardship, risk mitigation, and operational efficiency. In the South African context, TSFs embody both challenges and opportunities. By leveraging advanced technologies, adhering to stringent regulatory standards, and fostering collaboration among stakeholders, the country can address historical legacies, optimize resource recovery, and set exemplary standards for responsible mining. The sustainable management of tailings is an operational imperative and a commitment to the long-term well-being of communities and ecosystems impacted by mining activities.

1. The role of Tailings Storage Facilities at mines

Tailings are an inherent by-product of extracting and processing valuable minerals and metals from ore. As ore is crushed, ground, and processed, a liquid slurry composed of fine mineral particles, process water, and residual chemicals is generated. Effective management of these tailings is fundamental not only to the safe and sustainable production of metals and minerals but also to mitigating the associated environmental and societal risks. This chapter examines the multifaceted role of tailings storage facilities (TSFs) at mining sites, encompassing their design, operational strategies, and long-term implications.

The extraction of an economically recoverable commodity from ore inevitably produces waste materials, collectively known as tailings. These tailings typically range in particle size from sand to silt-clay and are largely influenced by the mineralogical composition of the ore and the processing methods employed. While ore is mined primarily to extract minerals such as copper, gold, silver, and other essential commodities, the tailings represent the residual matter left after these valuable components have been separated. Importantly, not all recoverable material is extracted during the initial processing due to technological and market constraints. Consequently, tailings may possess residual economic value, suggesting potential future opportunities for reprocessing as technology advances.

The construction and operation of TSFs represent a significant portion of the capital and operational expenditures in mining. Estimates suggest that initial capital costs for TSF construction can comprise approximately 15% of overall mine development, while ongoing operational costs are generally less than 5% of the total production costs. However, these figures underscore a crucial reality: the management of tailings is not a transient phase of mining but a long-term commitment that extends well beyond the mine’s active life.

From an environmental perspective, tailings management is pivotal to preventing the contamination of soil, water, and ecosystems. TSFs serve as a barrier against the migration of hazardous substances, ensuring that chemical reagents and fine particulate matter remain contained. This containment is essential for protecting both local communities and the broader environment from the potentially deleterious effects of tailings leakage or structural failure.

The lifecycle of a TSF extends into the mine closure and post-closure phases, which, in many cases, constitute the longest period of the facility’s existence. During these phases, TSFs transition from active containment structures to long-term environmental liabilities that require ongoing management, monitoring, and rehabilitation. Enhanced scrutiny of mine closure practices has led to expectations for improved land rehabilitation and comprehensive water management planning. Given that many TSFs remain in situ long after the cessation of active mining operations, ensuring their stability and safety is critical to mitigating long-term environmental risks.

The volume of tailings produced globally is increasing as ore grades decline and mining operations expand. Current estimates indicate that over 8 billion tonnes of tailings were generated in recent years, with copper mining alone accounting for nearly half of this volume. The number of active TSFs is substantial, with records suggesting hundreds of active facilities, though the total number—including legacy sites—likely reaches several thousand worldwide.

As the global demand for metals and minerals continues to rise—driven by population growth, infrastructure development, and the transition to renewable energy—the role of TSFs becomes ever more critical. Advances in materials engineering, risk assessment, and environmental monitoring are expected to drive innovations in TSF design and management. Furthermore, the potential reprocessing of tailings for residual commodities offers a dual opportunity for economic recovery and environmental remediation.

In South Africa, the approach to tailings management has undergone significant evolution. Traditionally, tailings dams were constructed directly on top of in-situ soils, capitalizing on the natural drainage properties of the local substrate. This method provided a straightforward means of managing tailings; however, it relied heavily on the inherent properties of the soil, which could vary widely from site to site.

In recent decades, there has been a marked shift towards the use of composite liners in tailings dam construction. Although this innovation introduces a new set of challenges—such as the need for fully engineered drainage systems in place of natural soil drainage, the potential for weak planes within the barrier system, and the imperative for meticulous stormwater management—it represents a significant advancement in the environmental safeguarding of TSFs. Upstream TSFs, in particular, demand an increased level of management to ensure that operations remain within the intended design parameters.

South Africa is home to a considerable number of TSFs, encompassing both active and legacy sites. While exact figures can be difficult to ascertain due to variations in reporting and management practices, it is estimated that hundreds of TSFs are currently active, with a far greater number of inactive or decommissioned sites still present across the country. Over decades, different mining companies have constructed these facilities according to diverse specifications and design philosophies. This lack of uniformity has necessitated a move towards standardized best practices, particularly through alignment with the Global Industry Standard on Tailings Management (GISTM).

Regulatory oversight in South Africa has historically been guided by SANS 10286 (1998), which outlines the principles and minimum requirements for the safe management of TSFs. Although this standard has provided a credible framework for risk mitigation, it has been recognized as falling short of more stringent international best practices. In response, SANS 10286 has been redrafted to align with the GISTM, with the revised document currently under final review by the South African Bureau of Standards. This regulatory evolution mirrors international trends, such as those reflected in Montana’s regulations (MCA 82-4-376), which mandate that TSFs be designed and operated using the most advanced practices and technologies available.

2. TSF design principles

Tailings dams are critical engineered structures designed to safely contain the slurry by-products generated during the extraction and processing of valuable minerals. Their design is governed by a complex interplay of geotechnical, hydrological, and environmental considerations, with various construction methods adapted to local conditions and operational requirements. This article provides a concise overview of the primary design principles and methods used in tailings storage facility (TSF) construction, with a focus on downstream, upstream, centreline, and single-stage designs, as well as the integration of composite liner systems and drainage components.

Downstream

Downstream tailings dams begin with the construction of an impervious starter dam. Tailings are discharged into the facility, and as the embankment is raised, each successive wall is built on top of the downstream slope of the previous section. With each raise, the dam crest moves downstream. This design is particularly suited to regions with high seismic activity and significant rainfall or water collection, where robust drainage and structural stability are critical.

Upstream

In upstream construction, the process also starts with a starter dam. Tailings are discharged and accumulate to form a tailings beach adjacent to the dam. As these tailings drain and consolidate, they serve as the foundation for subsequent embankment raises. In this method, the dam crest shifts upstream with each raise. Due to the reliance on natural consolidation of the tailings, upstream dams require a slow raising process and are typically implemented in areas with low rainfall and minimal seismic activity.

Centreline

The centreline approach is a hybrid of the upstream and downstream designs. In this method, the dam is raised vertically from the starter dam, ensuring that the crest remains fixed relative to upstream and downstream directions. This design can incorporate internal drainage features to enhance overall stability and is often chosen when site-specific conditions call for a balance between the characteristics of the other two methods.

Single-Stage Dam:

For smaller tailings facilities, a single-stage dam is constructed to full height in one operation without subsequent raises. This method simplifies construction and is generally applicable where the volume of tailings is limited, or where rapid construction is necessary.

Incorporating Composite Liners and Advanced Drainage Systems

The inclusion of composite liners introduces additional layers of complexity into TSF design. Composite liners, which typically consist of a high-density polyethylene (HDPE) geomembrane overlying a compacted clay layer, necessitate a thorough reassessment of drainage strategies. Unlike traditional designs that rely on natural in-situ soil drainage, engineered systems must now manage all water flows.

Above-Liner Drainage:

Drains positioned above the composite liner are essential to lower the phreatic surface (akin to the water table), reduce the seepage gradient, and diminish the liquefaction potential of the tailings. A herringbone pattern of drains, often spaced at regular intervals (e.g., 50 m), has been successfully implemented to achieve these objectives. This configuration not only mitigates the head on the liner but also replicates the natural basal drainage observed in unlined facilities.

Under-Liner Drainage:

Underliner drainage systems address issues related to trapped water beneath the geomembrane. They serve multiple functions, such as mitigating construction challenges (e.g., formation of ‘whales’ or softened foundation layers), providing a leakage detection mechanism, and managing seepage from adjacent existing facilities. Robust design measures, including the incorporation of protective bunds, sacrificial geotextiles, and redundant piping, ensure that these drains remain effective under varying operational conditions.

Stability Considerations and Stormwater Management

The stability of a tailings dam is assessed using limit equilibrium methods, treating the dam and its underlying soils as a unified system. The design must account for potential weak interfaces—such as the contact between tailings and the geomembrane—by incorporating appropriate safety factors and shear strength evaluations. In some designs, a flatter outer slope (e.g., 1:4) is mandated to reduce failure risks compared to steeper profiles used in older, unlined facilities.

Moreover, stormwater management is a critical component of TSF design. Paddocks or catchment areas at the dam’s toe are often integrated to capture and control stormwater runoff, preventing contaminated water from seeping into the surrounding environment. In advanced systems, inline attenuation ponds and solution trenches with periodic containment walls are employed to manage both base flow and peak stormwater discharges effectively.

The design of tailings storage facilities is a sophisticated exercise that balances structural integrity, environmental protection, and operational efficiency. Whether employing downstream, upstream, centreline, or single-stage methods, engineers must tailor each design to the specific geotechnical and hydrological conditions of the site. The integration of composite liners and advanced drainage systems further enhances the safety and sustainability of these facilities, ensuring that tailings are managed responsibly throughout the life cycle of the mine. As technology and regulatory standards evolve, continued innovation in TSF design will be essential to meet the challenges of modern mineral extraction.

3. TSF failures – global case studies

Recent years have witnessed several high-profile failures of tailings storage facilities (TSFs) around the world, underscoring the critical importance of robust design, stringent operational oversight, and proactive regulatory frameworks [1].

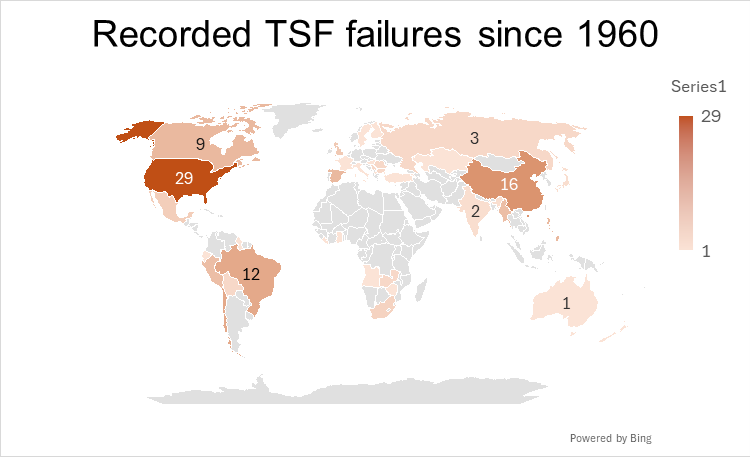

Figure 1: Total TSF failures per country since 1960, from [1]

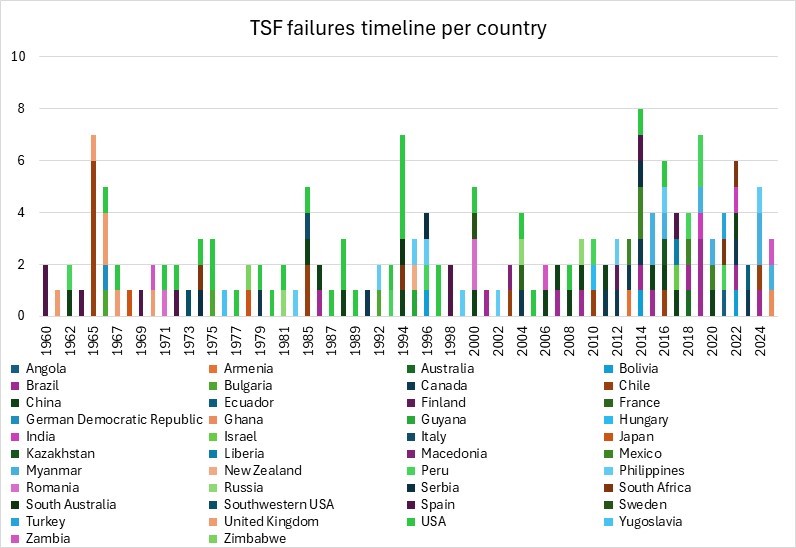

As shown in Figure 2, in the past two decades, there has been a notable rise in the number of tailings storage facility (TSF) failures worldwide, reflecting a convergence of factors such as aging infrastructure, inadequate original designs for current production rates, and evolving environmental stresses. While TSFs can be engineered and maintained to remain stable for extended periods—often well beyond their initial design life—there is no universally accepted “safe age” for these structures. Instead, their longevity hinges on factors including the quality of initial construction, ongoing surveillance, adherence to modern engineering standards, and the ability to adapt to changing climate conditions. In many instances, older facilities that have not been upgraded or thoroughly monitored are more prone to structural instability, highlighting the critical need for rigorous inspection, risk assessment, and, where necessary, retrofitting or decommissioning to ensure long-term safety.

Figure 2: Increase in TSF failures in recent decades.

On a broader scale, global reviews of TSF performance—such as those documented in recent academic and industry reports—indicate that failures are not isolated to one region. From uranium mining sites to large-scale metal operations, issues such as improper drainage design, insufficient freeboard, and inadequate long-term monitoring have been common themes contributing to structural breakdowns.

Zambia

In Zambia’s Copperbelt region, the collapse of the Chambishi TSF has been widely reported as a warning sign of underlying systemic issues [2]. This failure, described in a recent news article, highlights challenges in the region’s TSF management and maintenance practices. The incident has been characterized as a “canary” for the sector, suggesting that similar vulnerabilities could exist at other facilities across the Copperbelt, where rising production and aging infrastructure compound the risks.

South Africa

South Africa has also experienced significant TSF failures in recent history. Notably, the failure reported in the Jagersfontein area has drawn attention to the dangers associated with legacy facilities and the diverse construction methods used over decades [3]. Investigations into this failure revealed that variations in design specifications and differences in management practices and evolving regulatory standards have contributed to vulnerabilities in TSF performance. Efforts are currently underway to update existing standards—such as the revision of SANS 10286—to better align with global best practices and mitigate the risk of future failures.

Incidents of this nature reveal the severe impact that negligent mine waste management has on local communities. South Africa, which hosts the highest number of upstream tailings dams—a construction approach deemed unsafe and prohibited in some nations—stands as a stark example of this issue. It is therefore becoming paramount that mining corporations should not abandon unstable tailings dams, and that the government must implement stricter regulations and invest in the use of advanced dewatering technologies to protect both communities and the environment.

South America and Global Trends

In Brazil, the Turmalina Mine tailings dam failure has drawn attention to the complex interplay of environmental, geotechnical, and operational factors that can contribute to catastrophic incidents in regions with active mining operations. Preliminary accounts suggest that a combination of heavy rainfall, potential design vulnerabilities, and ongoing production pressures may have undermined the structural integrity of the TSF. Although detailed investigations are still underway, the Turmalina case underscores the importance of robust drainage design, rigorous monitoring regimes, and adaptive management strategies—particularly in areas where mining activities are expanding rapidly [4].

Similarly, the 13 June 2024 tailings dam failure at the Chinchorro TSF in Penablanca, Chile, highlights the continued challenges of maintaining TSF stability in a region marked by seismic activity and varying climatic conditions. Early reports indicate that unexpected water accumulation and potential weak zones within the embankment contributed to the dam’s failure. The incident has prompted heightened scrutiny of design standards and operational practices across Chile’s mining sector, reinforcing calls for stronger regulatory oversight and the implementation of advanced technologies—such as real-time monitoring and remote sensing—to prevent similar events in the future. Taken together, these recent failures illustrate the persistent need for stringent design principles, proactive risk assessment, and transparent governance to safeguard both local communities and the broader environment in South America’s resource-rich regions [5].

4. Filter presses and water treatment innovations for improved TSF management

Effective dewatering of tailings is a critical component of modern tailings management, as it enhances physical stability while balancing the need to preserve geochemical stability. By reducing the water content in tailings, operators can achieve a consistency that allows for safe, dry stacking. However, determining “how dry is dry enough” is a nuanced decision: while a drier tailings product minimizes risks such as groundwater contamination and reduces land requirements, maintaining some moisture is often necessary to ensure geochemical stability and prevent unwanted chemical reactions.

Conventional methods such as thickening are typically employed as a first step in dewatering, increasing the solids concentration of tailings from about 25% for coal tailings and red mud to as high as 40–50% for metalliferous tailings. To further enhance dewatering, technologies such as hydrocyclones and belt filters are commonly used. Hydrocyclones, for example, are cost-effective and simple to maintain, but they are limited in their ability to remove fine particles. Belt filters offer a compact footprint; however, their operational costs can be high due to the need for frequent maintenance and the use of chemical flocculants.

Among these technologies, filter presses—particularly those operating under high-pressure conditions—have emerged as a highly effective solution. Filter presses work by pumping tailings through a series of filter plates, which separate the water from the solids to form a filter cake. High-pressure filter presses are capable of achieving a high degree of water recovery, often reclaiming up to 80% of process water, which can be recycled back into the plant. The resulting filter cake, which can be dewatered to a solids content exceeding 80%, is stable, easy to handle, and suitable for dry stacking. This is particularly advantageous in remote or high-altitude operations where reduced equipment size and energy savings are critical. Additionally, the robust structure of the cake produced via high-pressure filtration ensures that it does not readily rehydrate, thereby enhancing its suitability for further processing or reuse as a construction material.

Overall, the adoption of high-pressure filter presses represents a significant advancement in tailings management. By optimizing dewatering processes, mining operations can lower the environmental risks associated with tailings storage, reduce capital and operational costs, and improve water recycling efficiency. As the industry continues to seek innovative solutions for sustainable tailings management, filter presses stand out as a promising technology that not only addresses immediate operational needs but also contributes to long-term environmental stewardship.

Filter presses are widely used in tailings management as an effective dewatering technology that transforms liquid tailings slurry into a compact, filter cake suitable for dry stacking or further processing. Essentially, the process involves pumping tailings slurry into a series of filter plate chambers where high pressure forces the liquid component to pass through a fine filter medium, leaving behind a solid cake. This cake, once dewatered to a high solids content, is stable and easier to transport and store than a conventional slurry.

Several critical characteristics of the tailings influent must be evaluated when sizing a filter press for tailings dewatering. First, the solids concentration plays a fundamental role, as it determines the volume of water that must be removed and directly impacts the overall throughput of the system. The particle size distribution is equally important; tailings with a high proportion of fine particles may slow filtration due to potential clogging, whereas coarser materials generally filter more readily. In addition, the rheological properties—including viscosity and flow behavior—must be considered, as these influence the energy requirements for pumping and the overall efficiency of the filtration process. Chemical composition is another key factor; the presence of flocculants, residual reagents, or variations in pH can affect both the formation and the stability of the filter cake. Finally, parameters such as temperature and variability in flow rate are significant, as they can alter the viscosity of the slurry and the dynamic loading on the equipment. Together, these characteristics guide the selection and sizing of a filter press, ensuring it meets the operational demands while maximizing water recovery and producing a stable, compact filter cake suitable for further handling or disposal.

When considering filter presses for TSF management, several key parameters must be evaluated:

- Feed Pressure and Cycle Time: The applied pressure is crucial for determining the efficiency of water removal. Higher feed pressures generally reduce the cycle time needed to achieve the target moisture content, thereby increasing throughput and reducing operational costs.

- Slurry Solids Content: The initial concentration of solids in the tailings slurry affects the dewatering efficiency. Optimizing the feed slurry consistency is important; too low solids content can slow down the process, while too high can lead to clogging or inefficient cake formation.

- Filter Cake Moisture Content: Achieving a high percentage of solids in the filter cake (often exceeding 80%) is essential for stability and suitability for dry stacking. The desired dryness level should balance the need for stability with the risk of rehydration when exposed to environmental conditions.

- Filter Cloth and Maintenance: The type and durability of the filter cloth are significant factors in the performance of a filter press. The cloth must withstand high pressures and repeated cycles while maintaining effective filtration. Regular cleaning and periodic replacement are critical to prevent clogging and ensure consistent performance.

- Water Recovery and Energy Consumption: Efficient water recovery is a key benefit of filter presses, with some systems reclaiming up to 80% of process water for recycling back into the plant. Evaluating the energy requirements and operational costs associated with the filter press is also important in determining its overall economic feasibility.

Effective dewatering of tailings at TSFs is essential for reducing the risk of structural failures and ensuring long-term environmental and operational sustainability. By removing excess water, dewatering technologies like filter presses significantly improve the stability of tailings, minimizing the potential for liquefaction and slope instability. Additionally, reducing water content in tailings prevents excessive rain ingress from overwhelming storage facilities, mitigating the risk of dam overtopping or failure.

Implementing filter presses early in the mine’s operational life allows for continuous management of tailings, preventing the build-up of large volumes of saturated waste that can be difficult and costly to handle at mine closure. Beyond enhancing TSF stability, the water extracted during the filtration process presents an opportunity for further treatment and reuse. Depending on the water quality, additional treatment steps—such as chemical precipitation, reverse osmosis, or biological treatment—may be required before reuse in mining operations or safe discharge into the environment. Alternatively, evaporation ponds can be integrated into the tailings management strategy to handle excess water, particularly in arid regions where natural evaporation can efficiently reduce volumes. These ponds can help concentrate residual contaminants, enabling their removal while reducing the environmental impact of untreated water discharge.

By incorporating dewatering strategies alongside effective water treatment and management solutions, mining operations can not only enhance TSF safety but also optimize water usage, reduce environmental risks, and ensure compliance with increasingly stringent regulatory requirements. Adopting these technologies early in the mine’s lifecycle is a proactive approach that minimizes long-term liabilities and contributes to more sustainable mining practices.

To all knowledge

To all knowledge