1 Overview of the Article

This article is written to give an overview of the stages involved in executing a pipeline project. There are different stages in executing a pipeline project; the construction and installation stages are the most visible. However, there are fundamental stages (Feasibility Studies and Conceptual Design) that must be executed appropriately before the detailed design and construction activities.

The Feasibility studies and conceptual design stage of a pipeline project are the preliminary stages of a pipeline project; they are the project’s planning stage.

While the feasibility studies focus more on the project’s viability, the conceptual studies or conceptual design tend to drive the technical ideas in executing the pipeline project.

This article will describe various activities performed during the conceptual design and feasibility studies stage.

In summary, this article will dwell on feasibility studies and conceptual design of a pipeline project. Most of the emphasis will be on the technical aspect. However, some aspects of the economic studies of a pipeline project will be explained.

Figure 1: Ongoing Pipeline Construction

2 Introduction

Embarking on a pipeline project is a rigorous task that must be well planned. Some pipelines traverse hundreds to thousands of kilometers across land and water bodies with various obstacles encountered along its routes.

In West Africa, there various ongoing and successfully executed pipeline projects.

The West Africa Gas Pipeline (WAGP) was conceptualized, designed, and installed to transport Natural Gas from Nigeria to Benin Republic, Togo, and Ghana. The pipeline was planned to supply gas to power plants and industries. The pipeline is 678Km in length and can transport 474MMSCF/Day of gas. The pipeline traverses both land and water as it travels along its route. From Itoki to Lagos beach is approximately 56km in length and is 30” in size. The remaining 569Km is 20″ in diameter and travels offshore from Lagos across the Benin Republic, Togo, and Ghana (https://www.wagpa.org/the-wagp/)

The Ajaokuta – Kaduna – Kano (AKK) Gas Pipeline is a 40” pipeline project undergoing construction as of 2020 in Nigeria. The AKK Pipeline is a section of the Trans Nigeria Gas Pipeline (TNGP) planned to transport gas from the southern part of the country to other regions. The AKK pipeline length is approximately 614Km, starting from Ajaokuta (middle Belt) to the Northern part of Nigeria. The pipeline will serve as a source of gas to power plants and other industries.

There are other pipelines transporting products, including Crude oil to various refineries, refined products to storage and distribution facilities, LPG to storage and distribution facilities.

From the few projects highlighted above, it can be deduced that typical pipeline projects are massive and cost millions to billions of dollars.

The physical execution (construction) phase of a pipeline is the most “visible” stage of a pipeline project; however, other activities must be executed before construction. These activities entail rigorous planning and preliminary design activities.

Typical stages of a pipeline project are feasibility studies, conceptual design, Front End Engineering Design (FEED), Detailed Engineering Design (DED), Fabrication Construction and installation, Commissioning, Operation, and Decommissioning. In some cases, there can be stages such as pre-feasibility studies, Pre-FEED depending on client requirements. The pipeline operation and decommissioning phase are mostly not part of the pipeline project stages. However, they are included because they must be appropriately covered in the pipeline’s planning and design stages.

Among all the stages of the project mentioned above, two stages are critical but mostly not heard of during the execution of a pipeline project. These stages are the Feasibility Studies and the Conceptual design stage.

3 Stages of a Pipeline Project

Though the article’s primary focus is feasibility studies and conceptual design, for clarity, below is a summarized description of all stages of a pipeline project mentioned in Section 2 above. It should be noted that a project does not necessarily need to pass through all the stages mentioned. In some cases, the Conceptualization stage is fused into the feasibility studies, with all conceptual design activities embedded in the feasibility studies. It is challenging to perform feasibility studies without performing key conceptual design activities because the conceptual design output data are used for cost estimation and determination of the project’s feasibility. The company may decide to perform Pre-feasibility studies before embarking on feasibility or conceptual studies. This is used to determine if the project is profitable.

3.1 Feasibility Studies

The feasibility studies aim to establish that the project is achievable, technically and economically. At the end of the feasibility studies, the most economically viable route option and pipeline diameter is selected. The client may perform the feasibility studies if they have the in-house capacity or contracted out.

During the feasibility studies, some of the activities performed include:

- Developing a clear project scope that will be executed during the various stages of the project.

- Project name is selected

- Project location is identified

- Clear description of the starting point of the pipeline and the endpoint.

- Various technical data, including pipeline size, possible pipeline routes, product volumes to be transported, are analyzed.

- Estimate the design life of the pipeline

- Preparation of project cost estimate and allocation of available resources.

- Perform Market analysis to determine the market

- Perform analysis to determine the viability/profitability of the project

- Operational cost is evaluated.

At the end of feasibility studies, a report with several attachments is generated detailing all the findings, including economic analysis, to aid decision-making to progress the project into the design stage.

During the feasibility studies, all the available alternatives such as pipeline start point, source of products (Gas, Crude oil, refined products, etc.), possible routings, envisaged customers, envisaged demand for product, are analyzed. At the end of the analysis, options not feasible are discarded. The evaluation of all options should cover the cost impact of each selected option.

At the end of a successful feasibility/conceptual studies, the project progresses into the design phase. Experienced engineers must perform the Technical aspect of the feasibility studies while experienced personnel with sound economic knowledge must handle the commercial aspect.

Note some of the input to be used for the commercial/economic analysis will be provided by the engineers; therefore, executing the cost estimate is collaborative teamwork by Engineers and commercial analysts.

3.2 Conceptual Design

This is the planning stage of a pipeline project. It entails producing ideas that will be used in executing the project. For every idea produced, the advantages and disadvantages are evaluated. The evaluation of the idea is not limited to technical; the commercial impact of the idea execution is critically evaluated.

The conceptual design is the primary design activities performed to minimize project execution errors, minimize cost, properly scope the project, and evaluate its feasibility.

Data gathering is a critical component of the conceptual design stage. These data should include population density along proposed routes, environmental data, reserved areas, gathering information on requirements and regulation covering the project area.

In this stage, preliminary pipeline routes are developed with several options documented for further consideration and review. This project execution stage requires critical brainstorming to device suitable means of executing the project.

3.3 Front End Engineering Design (FEED)

Front End Engineering Design (FEED) is also referred to as Preliminary Design or Basic Design.

Front End Engineering Design (FEED) is performed to bridge the Conceptual Design and Detailed Engineering Design gap.

The FEED utilizes the Concept design as inputs. During the FEED, all conceptual designs are elaborated, and the project detailed documentation commence. Only one of the proposed routes developed, selected after the conceptual design is further investigated and detailed during the FEED. During the FEED execution stage of the project, some of the activities to be performed include

- Perform a more detailed simulation and pipeline hydraulic studies

- Prepare piping and instrumentation diagram for the pipeline system

- Selected Pipe Route is further investigated, and if necessary, appropriate rerouting is performed.

- Obstacles along the route are adequately defined.

- All pipeline permits are obtained

- Commence preparation of datasheets.

- Pipeline preliminary alignment sheets are developed.

- Some of the pipeline specifications are developed.

- A more detailed Pipeline Wall thickness calculation is performed.

- Commence more detailed electrical and instrumentation design for the entire pipeline system, including cathodic protection system design.

3.4 Detailed Engineering Design

This is the last design stage of a pipeline project. The detailed designed documents are used for the procurement of all items required for the pipeline installation activities. If the FEED is detailed enough, some of the FEED documentation can be issued to prospective vendors, particularly long lead items such as pipes. Documents to be prepared and activities to be performed include:

- Perform detailed process simulation and hydraulic studies

- Prepare detailed piping and instrumentation diagrams (P&ID)

- Detailed Pipeline Wall Thickness calculation

- Road and Rail crossing analysis

- Preparation of detailed pipeline route

- Preparation of detailed pipeline alignment sheet

- Preparation of detailed crossing details and list

- Pipeline stress analysis

- Pipeline expansion analysis

- Prepare detailed datasheets for Line pipes, bends, isolation joints, pig traps, barred tee, etc.).

- Perform detailed design of all electrical system

- Perform detailed instrumentation and control system design

- Perform civil design was required.

3.5 Fabrication, Construction and Installation

This is the physical execution of the pipeline project. It encompasses the fabrication of pipes and fittings, clearing ROW, joining pipes, excavating pipeline trench, and installing the pipes.

Steel pipes are welded together and tested as per selected codes and standards.

The installation methodology depends on whether the pipeline is onshore or offshore. There are various techniques used for installing offshore pipelines. These are S-Lay, J-Lay, Towing or Reeling, while open cut, directional drilling, and non-directional drilling may be used to install buried onshore pipelines.

3.6 Pipeline Commissioning

Pipeline commissioning entails bringing the installed pipeline into service. When a pipeline is commissioned, it means the pipeline is ready for the transportation of products.

3.7 Pipeline Operation

Pipeline operation entails the efficient transportation of the product from the source point to its destination. All operating philosophies developed during the design stage are adhered to. Pipelines with a sound control system can be efficiently operated and monitored in a control room.

3.8 Pipeline Decommissioning

Decommissioning entails taking the pipeline out of service. Various procedures and plans are developed and followed to take the pipeline out of service.

4 Activities Performed During Conceptual Design/Feasibility Studies

This section will explain some of the activities performed during the feasibility studies and conceptual design of a pipeline project. To achieve a better economic judgment of the feasibility studies, I have decided to fuse the studies’ conceptual design activities.

It should be noted that there is no defined level of detail required for feasibility studies and conceptual design. However, the design must be good enough to be used for the pipeline economic analysis.

4.1 General Considerations

4.1.1 Source of Products (Gas, Crude Oil or Refined Product)

The idea of executing a pipeline project originates from transporting a product such as natural gas, refined products, and crude oil from one source to another.

All possible sources of the product are critically evaluated. If the intention is to import refined petroleum products into a country, all source points such as seaports, import berth platforms, and production reception facilities are evaluated. The evaluation is based on the product’s availability and the product’s cost at the source point.

4.1.2 Destination of the Product

The destination where the products will be transported is adequately defined. This location is based on different factors and the purpose of transporting the products, i.e., local consumption, processing or refining, storage etc.

If the pipeline is built to transport products for local consumption, a determinant factor is an available market. A detailed market analysis is performed that will aid the decision of the product destination. Premium motor spirit (PMS) demand is high in densely populated cities; therefore, a feasible destination for the product is a populated city.

If regulations restrict the storage of a product such as LPG in a city, its destination should be outside the city.

If the intention is to export crude oil, factors should include available export facilities such as seaports, existing crude export facilities etc.

4.1.3 Define the Means of Transporting the Product

Various options for transporting the product, such as rail transportation, road transportation or pipeline transportation, are evaluated. For average to long-distance transportation of petroleum products, a pipeline is the most feasible means of transportation.

4.1.4 Selection of Codes and Standards

The codes and standards’ selection process entails a detailed revision of country requirements, local regulations, requirements, the terrain of the pipeline, etc.

Pipeline transporting liquid hydrocarbons on land may be designed and constructed as per ASME B31.4 (Pipeline Transportation System for Liquids and Slurries), PD 8101-1 (Code of Practice for Pipelines; Part 1: Steel Pipelines on Land), while those transporting gaseous hydrocarbon may be designed as per ASME B1.8 (Gas Transmission and distribution piping Systems), PD 8010-1.

Offshore pipelines may be designed and constructed as per API RP 1111 (Design, Construction, Operation, and Maintenance of Offshore Hydrocarbon Pipelines (Limit State Design), DNV-OS-F101 (Submarine Pipeline System).

4.1.5 Define Required Facilities

A pipeline is not a stand-alone facility. It is usually connected to other facilities such as reception facilities, storage facilities, metering facilities, pigging facilities. The conceptual design should take into consideration all these facilities and how they impact the pipeline.

4.1.6 Analyze Project Impact on Community/Environment

A preliminary project impact study should be conducted. This is not the Environmental Impact Assessment (EIA) that should be performed in further project stages.

4.1.7 Identify all Stakeholders

Stakeholders in this contest do not mean the companies that own or operate the pipeline. Stakeholders are organizations/persons that can affect the project. Some of the stakeholders include:

4.1.7.1 Products Suppliers

They are a major stakeholder because the availability of the product affects the economics of the pipeline. Therefore a concrete agreement such as a product supply agreement must be reached with the supplier to guarantee product availability.

4.1.7.2 Government

Government is a major stakeholder. Therefore the government at the federal, state, and local levels must be involved in the planning and execution of the pipeline. The company should be aware of current government policies and envisaged future policies that can affect the project.

4.1.7.3 Ministries and Regulatory Agencies

Though the Ministries are part of the government, I decided to separate it because they play a key role during the planning and the execution of the pipeline project. Pipelines will not run entirely on fallow land, they cross rivers, roads, railways etc. therefore, all the responsible ministries, including the ministry of transportation and water, must be involved in the pipeline project planning. The ministries give final approval of the pipeline routing or recommend alternative routing; therefore, they must be part of the planning process.

4.1.8 Local Communities

The communities around the pipeline ROW are major stakeholders because the pipeline permanently resides in the community during its operational years. There must be a good agreement with communities along the entire pipeline proposed route. Pipeline vandalization is a significant problem. Therefore appropriate agreement must be reached with these communities to ensure that the pipeline is safe.

4.1.9 Other Stakeholders

Other stakeholders that may be directly or indirectly involved in the planning process are those the pipeline will temporarily or permanently affect their activities. During construction activities, there might be disruption to the movement of cars. Creating ROW access might affect farmers; therefore, all these persons must be informed of the pipeline’s effect on their activities.

Also, owners of existing pipelines, cables and other facilities that will be crossed or affected must be adequately informed and carried along during the planning and the execution of the project.

5 Selected Activities Performed by Various Disciplines

During the conceptual design or feasibility studies, design activities are performed by various disciplines. The process and the pipeline discipline are the key drivers; however, instrumentation and control discipline and electrical discipline provide considerable inputs.

Below are some of the key activities performed and documentation generated.

5.1 Process Discipline

Some of the activities performed by the process department include:

5.1.1 Throughput Estimates

The throughput is based on estimated demand and the planned volume of products transported from the source. After the demand is estimated, the actual quantity of products available for evacuation is calculated. The volume to be evacuated is the operating throughput of the pipeline. A margin is usually added to the operating throughput. This is referred to as the pipeline design throughput. Throughput estimation should also take into consideration future increase.

For clarity, below is an example of how to estimate pipeline throughput. I have assumed the research for product demand has been performed.

Company XYZ intends to evacuate 500,000 (Five Hundred Thousand) barrels of crude oil from its storage facility (tank farm) in a day. However, increasing the tank farm’s storage capacity by 50% in the future is possible. The company intends to evacuate 50% of the product by land and the remaining 50% by sea. Of the percentage to be evacuated by land, the company intends to transport 60% of the product by pipeline due to distance to the country’s northern part. However, the remaining 40% will be transported by rail/trucks to a refinery a few kilometers away.

Present Tankfarm Storage Capcity = 500,000 barrels

Future Tankfarm Storage Capacity = 1.5 x 500,000 = 750,000 barrels

Quantity of products to be evacuated by Sea = 0.5 x 750,000 = 375,000 barrels/day

Quantity of products to evacuated by land = 0.5 x 750,000 = 375,000 barrels/day

Quantity of products to be evacuated by rail/trucks = 0.4 x 350,000 = 150,000 barrels/day

Quantity of products to be evacuated by pipeline = 0.6 x 350,000 = 210,000 barrels/day

This implies future operating throughput = 210,000 barrels/per day

Giving a 10 percent margin for design throughput

Design Throughput = 210,000 x 1.10 = 231,000 barrels/day

Therefore, the pipeline must be sized to satisfy a throughput of 231,000 (Two Hundred and Thirty-One) barrels/day.

5.1.2 Pipeline Hydraulic Analysis

Pipeline hydraulic analysis is performed to determine the optimum pipeline size to meet the required throughput. The pump head is required to transport the product from the start point to the destination.

Liquid hydrocarbon pipeline pressure loss can be predicted using the Darcy correlation methods.

Other equations that can be used to estimate pressure loss in liquid hydrocarbon pipelines include:

Modified Colebrook-White Equation, Hazen-Williams Equation is mostly used for a pipeline transporting refined products pressure loss calculations.

Gas pipeline pressure drop can be estimated using the American Gas Association (AGA), Modified Colebrook-White Equation and other available equations.

Software is generally used for hydraulic analysis. However, at this stage, spreadsheets developed in-house can be utilized.

The estimated pressure drop will determine the number of pump stations or compressor stations along the pipeline.

5.1.3 Prepare a Process Flow Scheme for the Pipeline

The flow scheme should show the pipeline characteristics such as diameter, metering stations, block valve stations, pig traps, off-takers etc.

5.1.4 Process Description

The process department must give a clear description of the entire pipeline system. All the equipment required along the entire pipeline facility must be clearly stated.

Process description should clearly define

- Pipeline diameter or all the options under consideration.

- Product reception facilities

- Pump or compressor stations as applicable

- Pipeline operation philosophy

- Pigging philosophies

- Metering requirements

- Requirement for pipeline line break valves

5.2 Pipeline Discipline

The pipeline department performs activities including

5.2.1 Pipeline Routing

Pipeline routing is performed to determine optimum pipeline routes. Various routes are developed, but most times, three options are developed to aid easy decision making. See below an example of a pipeline route developed using satellite imagery.

Figure 2: Example of Pipeline Route (For Illustration Purpose, Wrong Coordinates)

The routes are developed through a desktop study, utilizing various software or data. Routing is performed utilizing satellite imagery, which may be bought or provided in the software.

One of the most widely used software is google earth. Other software includes ArcGIS, QGIS etc.

Google earth can be used to obtain coordinates of desired locations on the proposed routes. The software also provides elevation information that can be used for preliminary pipeline planning and can be used to visualize the level of geographical development over time. This can be used to predict future development along the pipeline route.

Also, features such as roads, railways, rivers, mountains, reserved areas etc. can be easily identified on google earth.

When pipelines are traversing water body’s critical information can be obtained from Admiralty Charts. These charts give detailed information about the location of offshore infrastructures, including pipelines, cables etc. They also give information on the location of the wreckage, anchoring zones, seaports etc.

Most importantly, the depth of water at a specific location is shown on admiralty charts. It should be noted that updated versions of the chart should be obtained during the conceptual design stage.

The information obtained from all software and admiralty charts is only utilized for the conceptual design. Detailed surveys and investigations are required as the project progresses into the FEED stage.

When developing the routes, some of the criteria’s to consider include:

- Minimize traversing areas of complicated construction. Usually, side slopes should be avoided as well as mountainous terrain. The pipeline should only be routed through areas of complicated construction when there are no feasible alternatives.

- Minimize overall pipeline length. The cost of a pipeline project is a function of pipeline length, therefore as much as possible, the length of the pipeline should be minimized.

- Route the pipeline through locations to minimize environmental impact during construction and operation of the pipeline.

- Avoiding areas where unstable ground has been identified. Usually, it is difficult and more expensive to construct pipelines in swampy terrain and unstable ground. Therefore locations of unstable ground should be avoided.

- Avoid areas of high population density. Built-up areas should be avoided because it results in a higher construction cost. The increase in cost results from paying for damages to procure thicker pipes resulting from a higher location class designated in respective design codes and standards. Also, there is a delay in construction activities in populated areas.

- Minimize impact on agricultural activities.

- Minimal security risk to the population and pipeline. It is recommended to locate pipelines far away from residential areas. The BS codes and other codes prescribe the minimum Building Proximity Distance to a pipeline. Another critical consideration is pipeline vandalization. When a pipeline is easily accessible to the population, the probability of vandalization increases.

- Minimize total cost. The minimal cost results from a thorough evaluation of criteria detailed in this section and other technical considerations.

5.2.2 Identify Obstacles along Proposed Routes

During this stage of the project, identifying obstacles should be performed and factored into the cost estimates. Visible obstacles such as river crossings, road crossings, railway crossings and locations that will require special technology to install pipeline should be adequately defined.

Most of these obstacles can be easily spotted on satellite imagery. If necessary, a site visit can be performed to define obstacles of interest appropriately. A table or an attachment of identified obstacles should be prepared. This table should show the coordinates of these obstacles, the type of obstacle, the length of the obstacle and the proposed method of crossing,

If not identified, these obstacles can lead to large variations in the cost estimate as the project progresses.

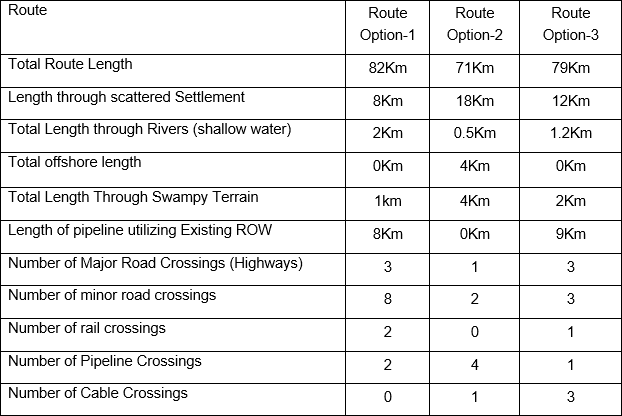

5.2.2.1 Comparison of Identified Routes

After all routes and obstacles have been identified and documented, a table of comparison should be prepared to show each route’s properties. Below is a tabular comparison of three routes.

5.2.3 Preliminary Wall thickness Calculation

The wall thickness is a critical activity that is performed during the feasibility studies and conceptual design. A large percentage of pipeline project results from the procurement of pipes and fittings. Therefore the wall thickness must be estimated during this project stage. The wall thickness is calculated as per the selected codes and standards; however, the wall thickness will be optimized as the project progresses. It is better to be conservative in estimating the wall thickness during this stage of the project.

5.2.4 Develop Pipeline Facility Concept

The pipeline department should develop a facility concept in conjunction with the process department. The concept should take into consideration pipeline construction methodology.

Some of the concept to develop include

5.2.5 Prepare a Preliminary Pipeline MTO

The pipeline discipline prepares an MTO covering the entire pipeline system. When there is more than one route option, the MTO for each option must be prepared. The MTO will be used in estimating the cost of the pipeline materials.

5.2.5.1 Define Pipeline Material and Grade

The Line pipe material and the grade should be specified during this stage of the project. The grade will be used in the estimation of wall thickness. The material may not change as the project progresses; however, the pipe grade may change. Pipe material grade may change because there might be a need to use grades that result in thinner or thicker wall thickness for offshore pipelines and reduce weight because of higher transportation cost and technical reasons resulting from stress-related issues. Most pipelines are constructed of API 5L pipe materials, with grades ranging from Gr. B to Gr. X120.

5.2.5.2 Develop Preliminary Pigging Facilities

The pipeline engineer should select a location for pig launchers and receivers. If intermediate pigging stations are required, this should be well documented because they will add significantly to the project’s cost. The coordinates of these locations are tabulated in the report.

5.2.5.3 Pump or Compressor Stations

Pipeline traveling long-distance required intermediate pump stations or compressor stations to boost the pressure. The process department will specify the number of stations required. However, selecting the location should be done by a joint team of the process and pipeline engineer. All the locations and coordinates should be indicated on the routes.

5.2.5.4 Metering Stations

All metering stations along the pipeline route should be adequately defined with their coordinates documented.

5.2.5.5 Define Pipeline Inline components Fitting and Flanges

The class rating of all fittings should be defined, locations of other inline components such as isolation joints should be documented.

5.2.5.6 Line Break Valve/ Block Valves Station

The pipeline department should define the location where sectionalizing valves will be located along the entire route. The locations should be shown on the route maps and the coordinates documented in the report.

5.2.5.7 Corrosion protection

The pipeline department should also specify the type of corrosion protection for the pipeline. Also, the type of external coating for the pipeline should be specified.

5.2.5.8 Pipeline Construction

This is very critical as construction activities contribute significantly to the cost estimate. The envisaged construction method for sections of the pipeline should be specified. If unique installations are required for roads, rivers or rails, this location should be documented with the envisaged construction method.

The inability to predict the construction method can result in significant construction cost changes because special construction technology such as horizontal directional drilling can significantly increase the pipeline project’s cost.

5.3 Instrumentation and Control

The I&C department is responsible for developing the pipeline instrumentation and control system concept. This should be part of the final report. Also, an MTO covering the entire system should be developed.

The control system should describe how all instruments installed on the pipeline will communicate with various control systems; how the information will be accessed, processed, and transmitted.

At this stage of the project, the envisaged system architecture should be developed to improve as the project progresses.

The components of the control system should be adequately explained in the report. Typical examples of components of a control system that should be part of the report are:

5.3.1 SCADA System

The SCADA system monitors and control the pipeline facilities in a timely manner and provide a centralized alarm, event management, operation and management reports for the entire pipeline facilities. The SCADA system also ensures proper pipeline shut down by closing pipeline facilities in a planned manner in an emergency.

5.3.2 Station Control System

All stations, such as pigging stations, metering stations, and block valve stations, should have a control system developed with their programmed algorithms assuring the pipeline’s safe operation. The I&C department should give a detailed report on how to integrate the entire stations.

5.3.3 Fail Safe System

The Fail-Safe System, which may contain the fire and gas system and emergency shutdown system, should be adequately detailed in the report.

5.3.4 Process Instrumentation

The report should detail the process information gathering devices. Some of the process information that requires gathering and monitoring in a pipeline system are pressure temperature, flow rate, density, pig detection.

5.3.5 Telecommunication System

The report should give detailed information on the overall network topology and the network components.

5.4 Electrical Department

The feasibility/conceptual design report should have inputs from the electrical department. The inputs should cover power requirements for facilities that are part of the pipeline system, such as pump or compressor stations, block valve stations, metering stations.

Also, components of the entire power system should be documented appropriately.

A preliminary MTO covering the entire electrical system should be developed. This will form part of the cost estimate.

6 Commercial/Economic Analysis

6.1 Budgetary Cost Estimate

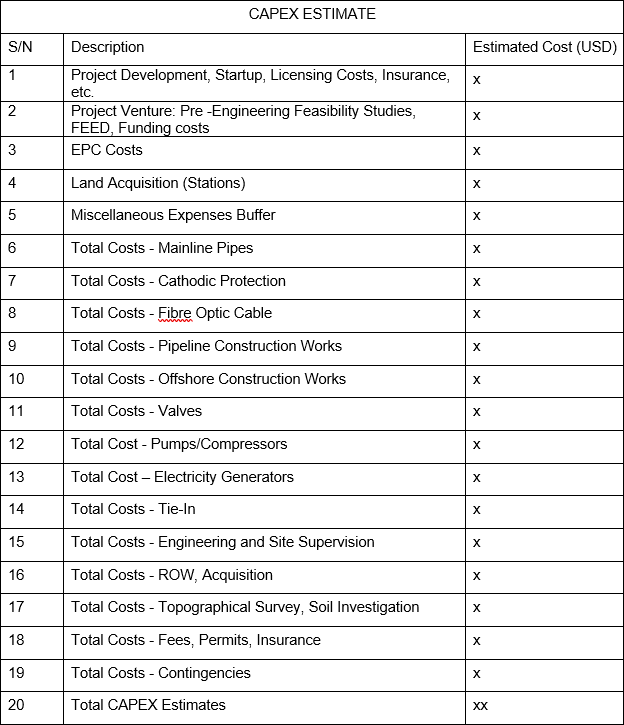

Based on the conceptual design, a cost estimate is prepared. A separate estimate should be prepared for each route and pipeline diameter.

The estimate may cover both CAPEX (Capital Expenses) and OPEX (Operating Expenses)

Competent persons should prepare the estimate. The persons should have access to data containing the cost of items in the MTO prepared by each department.

The budgetary estimate should include design, engineering, procurement, construction, testing and inspection, and commissioning of the proposed pipeline.

The cost estimate may be based on in-house cost data; the items’ cost may be sourced from vendors. When data are sourced from vendors outside the country, Increased cost resulting from import duties and transportation should be factored into the estimate.

Usually, the cost estimate’s accuracy is per the recommendations of AACE (Association for the Advancement of Cost Engineering). Kindly refer to AACE Recommended Practice No. 18R-97 for more information on cost estimation and accuracy.

Usually, a class 4 estimate is sufficient for this stage of the project.

Based on the cost estimate output, only one option is selected. This option covering pipeline diameter and the selected route will be further elaborated in the FEED stage.

At the end of the estimate, a detailed estimate for each option is presented in tabular form, and a summary of each option is also presented.

Below is an example of a budgetary cost estimate summary.

6.2 Market Analysis

Market analysis is a key component of feasibility studies. It is performed to determine the viability of the project. This is performed to determine the rate of demand for the product, the size of the market and how long the market size and demand can be sustained. The output of this analysis is included in the feasibility study report.

7 References

The West African Gas Pipeline (WAGP): https://www.wagpa.org/the-wagp/

Ajaokuta – Kaduna – Kano Pipeline: http://oilservltd-ng.com/olmls/AKK2.php

To all knowledge

To all knowledge