1 Engineering Integration at Work

Civil Engineering Works at Tank Farms: Tank farms are exciting places for engineers: there are few examples of how the variety of engineering disciplines have to co-exist, cooperate and integrate as much as in these intimidating, imposing and impressive facilities. Most people think that tank farms, with their storage vessels, pipes and pumps, are the exclusive hunting grounds of mechanical and chemical engineers, while civil engineering is about structures, roads, water and concrete, right? Exactly… but let’s start with a bit of context.

2 The Business of a Tank Farm

The storage of hydrocarbon and other chemical products is necessary for many sectors of the economy to support industrial or commercial operations.

The storage of hydrocarbon and other chemical products is necessary for many sectors of the economy to support industrial or commercial operations.

At the large enterprise end of the spectrum, tank farms are built to receive, store, process and distribute product to consumers. This often means that the facility is geographically placed at the interface between transport modes – for example, to receive the product from an off-shore pipeline and deliver via dispensing trucks or rail. At the smaller end, a tank farm may be built to uniquely serve the operations of a factory or an airport and to secure continuity of supply.

Mega tank farms, some owned and operated by governments, are used as buffers against the volatility of price or supply. One of the largest tank farms on the planet is located in Pengerang, Malaysia: the site can hold 420,000 cubic metres of crude (2.6 million barrels) and provides blending and distribution services. The Houston Fuel Oil Terminal Company, reportedly the largest oil storage terminal on the US Gulf Coast, has a capacity of more than 13.8 million barrels. In the Emirate of Fujairah, the UAE is presently building the world’s largest underground crude storage facility with a capacity of 42 million barrels. Imagine the size of this thing!

Notwithstanding size and purpose, all tank farms are business enterprises in their own right. Besides the commercial motive, their continuity, safety, efficiency and environmental impacts are the topics of compliance with regulations and service level agreements with consumers. The facility has to be designed against the backdrop of these realities. Enter the civil engineer…

3 Tank Farms as Strategic Facilities and Key Points

Petroleum products and other chemicals are undeniably critical to the functioning of every economy on the planet. If an airport tank farm ceases operation, planes don’t take off. If the fuel supply at a commercial farm runs out, crops don’t get harvested.

The risk goes beyond economics: tank farms are hazardous places. Fires, explosions and release of chemicals are a risk to humans, infrastructure and the environment. Because of where they are placed, catastrophic failures at tank farms will create disastrous effects all around. Safety and Reliability Engineering, Fire Engineering, and Control and Instrumentation (C&I) are key disciplines in tank farm operations and utilise sophisticated early warning detection, protection and shut-down systems.

More than one-fifth of tank farm failures are attributable to human error, and over half are due to tank failures. Advances in IoT, automation, digitalisation and artificial intelligence, predictive maintenance and geomatics are revealing new opportunities for engineers to understand, anticipate, predict and mitigate the risks. The global growth in environmental awareness, plus political (and statutory) and societal pressures to reduce carbon emissions will accelerate these developments.

Tank farms are ideal targets for malicious attacks. They require physical security and protection infrastructure and management systems worthy of a military installation. Here too, there is a rise in the application of AI and intelligent detection science. The civil engineer is a key member of the professional team responsible for security, given the obvious implications for the design of physical infrastructures such as perimeter walls, access points, canopies and internal protective walls.

Tank farms are ideal targets for malicious attacks. They require physical security and protection infrastructure and management systems worthy of a military installation. Here too, there is a rise in the application of AI and intelligent detection science. The civil engineer is a key member of the professional team responsible for security, given the obvious implications for the design of physical infrastructures such as perimeter walls, access points, canopies and internal protective walls.

4 Standards and Specifications

Why standards and specifications? Consistency, efficiency, quality and integrity of design and operations are the keywords here, for all the good reasons of safety, security and environmental protection already mentioned. It is useful to be aware of the integrated system of standards that inform the civil designs and construction works in tank farms.

The petroleum industry relies on national and international bodies to develop specifications and codes of practice. Examples are the International Organisation for Standardisation (ISO), the American Petroleum Institute (API), the British Standards Institution (BSI), the American Society of Mechanical Engineers (ASME) and the Society for Petroleum Engineers (SPE). Their specifications and codes, and specifically those of the API, are considered the de-facto international standards and often form the basis for national or regional standards. But in a particular country or region, there will be differences to account for local contexts and practices.

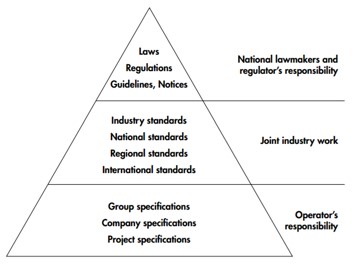

The Association of Oil and Gas producers explains the hierarchy of standards as follows:

The need for a harmonized global approach has been pushing the industry towards international standards based on the ISO system. Several API codes have already been transferred to ISO to become global ISO standards.

Safety, health and environmental protection, in conjunction with best practices in quality management – collectively, SHEQ – is a discipline in its own right. Practitioners qualified to implement an integrated SHEQ management system comprising of safety and health (OHSAS 18001 or its local equivalent), environmental management (ISO 14001) and quality management (ISO 9001) are mandated and indispensable role players in petroleum projects and operational teams.

Engineers are used to working with standards, so nothing new here: there are industry-specific design codes for fuel tanks, pipes and pumps, reinforced concrete structures, earthworks and treatment of contaminated effluent, and specialist are no strangers to these. For civil engineers, the challenge is to discover how the standards applicable to tank farms inform and shape their application of discipline-specific standards: the design of a drainage system is simple enough to do, but it has to comply with the requirement to separate contaminated- and stormwater run-off. It is often at the interface between a civil design and a mechanical system where detail is overlooked.

Engineers are used to working with standards, so nothing new here: there are industry-specific design codes for fuel tanks, pipes and pumps, reinforced concrete structures, earthworks and treatment of contaminated effluent, and specialist are no strangers to these. For civil engineers, the challenge is to discover how the standards applicable to tank farms inform and shape their application of discipline-specific standards: the design of a drainage system is simple enough to do, but it has to comply with the requirement to separate contaminated- and stormwater run-off. It is often at the interface between a civil design and a mechanical system where detail is overlooked.

The engineering disciplines involved in a tank farm do not act in isolation – to develop a solution, they have to integrate their respective contributions, cooperate with SHEQ practitioners, planners, architects, environmental consultants and C&I specialists, and account for the operator’s management system requirements. This says a lot about the need for civil engineers to widen their scope of consideration, bring systems thinking to the table and become acquainted with new technologies. A new breed of the civil engineer is in the making…

5 Civil Engineering Works: Facilities and Services

5.1 Roadways and platforms

Except in the perfectly automated tank farm of the future, vehicles and people are integral parts of the facility. Fuel dispensers and loaders manoeuvre to loading and metering bays, service vehicles carry technicians between workshops and pump bays, personnel walk from point to point, contractors and visitors, arrive, park and leave. These movements require roads, parking areas and platforms of various types and sizes.

Civil engineering comes into its own in this domain – the site layout plan is a starting point, accompanied by a conceptual design to serve operating requirements. Basic designs will consider design vehicles (i.e. vehicle classes, their operating loads and speeds, and turning circles), pedestrian movements, tank farm operations, drainage and soil conditions. The geometric design will specify gradients, space and layouts to optimise earthworks, assist operating flows and ensure the safety of movement. The roadway and platform design will put down a layered structure capable of carrying vehicles over its design life (often 20 years and more) and channelling rainwater run-off.

It is common for detail road designs to consider several options. Roadways and parking surfaces could be built of gravel, asphalt or concrete, and drainage could be along open (grated) channels or pipes. The engineer will evaluate the options by considering the appropriate standards, soil characteristics, available materials, constructability and economic parameters, as well as the impact on operations and maintenance when making a detail design recommendation to the client.

Tank farm loading platforms have to be impermeable and resistant to damage by the product and fire, and containment must be provided in the case of spillage. Mostly, this leads to the decision to use Portland Cement Concrete – also because it presents a life-cycle cost advantage with regards to maintenance.

A critical input to the design work is a geotechnical survey, which will assess the geology of the site and the surrounding area, collect meteorological and hydrological data, assess seismic activity and perform in-situ and laboratory tests of soil characteristics. These surveys and tests have to be carried out by a geotechnical specialist who will produce a report with recommendations about drainage, the suitability of in-situ materials as foundations, and special soil treatments that may have to be applied. Of specific concern to civil engineers is the presence of clay (which would be susceptible to heave and settlement), collapsible soils and corrosive materials. Soil mechanics, a discipline of civil engineering, is a well-established science and design codes make provision for handling the variety of conditions likely to be encountered during projects.

5.2 Buildings and structures

Planners and architects will play the leading role in the design of administrative buildings and workshops, and they will do so with due attention to the relevant building codes, safety specifications, functional requirements and human needs. Working in a tank farm is a hazardous business, and the intention is to make these facilities comfortable, functionally effective, safe and, increasingly, green.

These designs should include the inputs of civil engineers and their colleagues from the oil and gas and C&I disciplines, who can incorporate into the planning the constructability of designs and requirements for safety and effective interfaces to operations. The designs and construction must achieve structural and functional integrity, for which the civil engineer will complete detail designs of columns, footings and foundations, reinforced concrete walls, floors and roofing structures.

Similar to the requirements for roads and platforms, the geotechnical characteristics of the site will feature prominently in the design of footings and foundations, and the design of structures to withstand lateral pressures, seismic activity and the design loads.

The civil engineer’s responsibility does not end with designs, of course. During the procurement and construction phases of the project, she has a critical contribution to make in oversight, quality control and commissioning. In these matters, it is the engineer’s primary accountability to produce an outcome in keeping with standards, and protect the interests of the client and the users of the facilities.

5.3 Drainage

When it rains, water wants to run to the lowest point. During heavy downpours, this run-off can flood operations and become a safety hazard, in few places more acute than a tank farm with its containment structures. Civil engineers take account of hydrological information and the geotechnical survey to design drainage capacity for the water volumes generated by a storm size of selected recurrence probability, say a 1 in a 20-year flood. Drains have to have a gradient of specified minimum, say 0.6%, to prevent the drainage system from acting as a reservoir and must carry run-off away quickly and effectively.

Contaminated run-off is particularly important to design for, because of the requirement in industry codes to separate and contain such effluent. To prevent contamination of external stormwater drainage systems, effluent drainage should be capable of release to natural courses only when safe to so, namely when hydrocarbons have been sufficiently separated and removed to achieve water quality in keeping with local discharge standards.

Contaminated run-off is particularly important to design for, because of the requirement in industry codes to separate and contain such effluent. To prevent contamination of external stormwater drainage systems, effluent drainage should be capable of release to natural courses only when safe to so, namely when hydrocarbons have been sufficiently separated and removed to achieve water quality in keeping with local discharge standards.

Civil engineers design the structures, pipes and channels that will carry and contain spillage and contaminated run-off. The containment structures typically include bunded areas (say around pump bays), separator vessels (in which contaminated effluent is treated mechanically, chemically or organically) and attenuation dams (to contain a sudden large volume of run-off and control its release). All of these structures require a civil engineer to design their capacity (again, industry codes prescribe the standards and parameters to be used) and functional operation. Separator tanks could be built on-site as a reinforced concrete structure, but specialised vessels and technologies are also commercially available. No matter the type, containment and treatment vessels require earthworks and foundations which is uniquely civil engineering territory. Again, geotechnical information is an important input to the design process.

Spillage in tank farms has the potential to permeate and contaminate groundwater. Many tank farms include in their designs monitoring wells to enable continuous measurement, reporting and planning to mitigate the risk of pollution. The geotechnical survey is of great assistance here because it will identify the level of the groundwater table and how in-situ materials may assist or impede ingress of contaminants.

5.4 Special structures and facilities

Tanks in a tank farm, and any other functional system that may spill hydrocarbons (e.g. the loading bay), have to be placed in bunded containment areas, for which there are specific standards and design requirements. Bund walls and floors must, for example, be water-tight and able to withstand the rush of a large volume of fuel in the event of a tank rupture. For large vessels, this translates into reinforced concrete retaining walls and foundation structures. This translates into more civil engineering design and construction work.

Around a tank farm, various functional systems such as filter bays, loading bays and pump stations are placed on foundations and bunded platforms that are impermeable and resistant to damage from product and fire, and of course able to accommodate the static and dynamic loads imposed on them. Their protection with firewalls and canopies to direct rainwater elsewhere require structural design work. Think civil engineering, again!

Appurtenant to these structures is the steel furniture of elevated walkways and stairs, inspection gantries, work platforms and the structures to support overhead cranes, pipes and equipment. The civil engineer with a love for steel has all the challenges ever to be desired!

Appurtenant to these structures is the steel furniture of elevated walkways and stairs, inspection gantries, work platforms and the structures to support overhead cranes, pipes and equipment. The civil engineer with a love for steel has all the challenges ever to be desired!

6 Conclusion

Civil engineers have always been and will remain, an indispensable element of how tank farms are planned, designed, built and operated. It is just that their contribution is not that visible to the casual observer, what with the size of the thing and all the intimidating tanks, pipes, pumps and valves around. Look a little deeper, and you will discover a world with magnificent challenges and exciting solutions for which civil engineers are uniquely qualified. Here’s to the civil engineers who make our buildings trustworthy, our roads and dams functional, our tank farms productive and safe, and our world overall a better place to live in!

Read more about EPCM Storage here

7 References

https://oilfiltration.globecore.com/characteristics-types-purpose-tank-farms/

https://www.eia.gov/todayinenergy/detail.php?id=21552

http://lightningsafety.com/nlsi_lls/Causes-of-Failures-in-Bulk-Storage.pdf

Florea, Gheorghe and Popa, Marian – Safety and Security Integration in LPG Tank Farm Process Control in Proc of the 14th IFAC Symposium on Information Control Problems in manufacturing, Bucharest, May 2012

https://www.digitalrefining.com/article/1001311,Automation_of_tank_farm_systems.html#.XjEq5y17FsY

https://www.extractiveshub.org/servefile/getFile/id/5185

http://www.ogp.org.uk/pubs/426.pdf

http://www.iogp.org/wp-content/uploads/2016/12/Standards-Issued-2017.pdf

To all knowledge

To all knowledge