LPG has dramatically impacted our world since its discovery in 1910 by Dr. Walter O. Snelling. It changed how we cook, heat our homes, drive our cars, and store our food in a cool environment. However, LPG can be destroyed if not properly handled, stored, and managed. To enable us to do all this safely, international and local codes and standards have been developed to provide legislation and guidance to designers, distributors, operators, etc. This article compares the site layout guidelines for bulk LPG storage between the NFPA (National Fire Protection Association) 58 and SANS (South African National Standards) 10087 3 codes and standards. This article only intends to indicate major differences when designing a system. Reference should be made to the original codes and standards. Specific project requirements were not included in this discussion.

1 NFPA and SANS standards concerning LPG

1.1 NFPA 58 2014 Edition

NFPA (National Fire Protection Association) is a global non-profit organisation that has developed codes and standards for usage and adoption by governments and many institutions worldwide. Many of these codes and standards are also used by the South African government as part of the SANS suite of standards enforced to be used as a minimum requirement on South African installations. NFPA 58 has been developed as an industry benchmark for safe bulk LPG storage, handling, transportation, and use. NFPA 58 mitigates risks and ensures safe installation, preventing failures, leaks and tampering that could lead to fires and explosions.

1.2 SANS 10087 3 2008 (Edition 4)

The South African set of codes and standards for LPG installations is based on various British standards, NFPA publications, and international best practices.

SANS 10087 is divided into several different parts. Part 3 covers the bulk storage of LPG and will be compared with the NFPA 58 standard in relation to plant layout requirements.

2 Containers and associated equipment

When planning the layout of a bulk LPG storage facility or a single tank, the SANS 10087 part 3 and NFPA 58 standards can be used as a guideline for executing the design planning and layout of the facility correctly.

2.1 Location of Bulk LPG Storage Containers

The location of the bulk storage containers is a major component that will guide the overall layout of the facility, as well as the safe maximum storage volumes that fit the plot area in terms of the standards. In this section, the placement of storage containers will be discussed. The layout constraints will prescribe the maximum container size and, therefore, the maximum quantity of LPG storage allowed on the site, subject to environmental impact and major hazardous installation constraints. Only the placement of the container is discussed below, along with other constraints outside of the scope of this article.

Figure 1: Comparison between NFPA58 and SANS 10087-3 for storage container locations.

The comparison was summarised to explain the differences between the codes. The code references in the brackets refer to NFPA 58 2014 Edition and SANS 10087-3 2008 (Edition 4).

Regarding bundled areas around the above-ground storage containers, a conflict in recommendations is perceived at first glance. When studying this, both codes recommend protecting adjacent areas from the accumulation of heavier-than-air explosive gasses and directing gases away from unprotected areas by using slopes or vapour barriers/dykes.

It is recommended that you consider both codes to ensure that you comply with safety regulations.

2.2 Storage Container Spacing (Buried, Mounded and Above Ground)

Spacing of storage containers is important for the safety of the container next to it and general facility safety. The following section will deal with the different types of LPG storage methods and which codes and standards are applied to each situation.

2.2.1 Buried (SANS), Underground (NFPA) or Mounded LPG Storage Tanks

NFPA 58 Code specifies that ASME Containers are to be used as bulk storage containers. The SANS codes allow ASME-approved container design and PD 5500, formally a widely used British Standard BS 5500, in the design fabrication and inspection of (unfired, fusion welded) pressure vessels.

When considering aboveground/mounded tanks, both codes give similar distances to property boundaries (between 3m and 15m) depending on the container size.

Figure 2: Comparison between safety distances specified by NFPA58 and SANS 10087-3 for underground/mounded LPG containers.

As per the previous comparison in Figure 1, the safety distance comparison above also indicates similar requirements, and it is recommended that you follow both code recommendations for good engineering practice.

Figure 3: Example of a buried (underground) tank – as shown, the tank has a concrete barrier around it and should have proper ventilation and liquid gas collection, like at the bottom, following the standards and codes to remove any LPG spillage (for the prevention of fluid accumulation and volatile environment creation).

Figure 4: Example of mounded storage tanks—Compared with above-ground installation, safety distances are minimized. This method consists of semi-burying tanks so that a distance from the centre of the tank to a length above the tank is covered with either soil or concrete.

2.2.2 Above Ground Storage Tank

The following section deals with the codes and standards for above-ground storage tanks. Both codes and standards use safety separation (distances) methods related to the LPG bulk storage container size volume. NFPA is more conservative, with larger separation distances for containers larger than 114m3 increasing from 15m and specifying distances up to 122m for containers exceeding 3785m3. SANS codes limit the safety distances to 30m for containers exceeding 265m3.

Figure 5: Comparison between safety distances specified by NFPA58 and SANS 10087-3 for above-ground LPG containers.

While both codes give similar safety distances up to 265m3, SANS is more conservative with smaller containers, and NPFA is significantly more conservative with large containers.

Figure 6: depiction of an above-ground LPG storage container installation. In this case, the installation was an appropriate distance away from buildings, loading bay etc. hence why there are no bunds, dykes etc. installed.

2.2.3 Rules About Groups of Containers and Other Requirements

The following section deals with LPG bulk storage grouping. Both NFPA 58 and SANS 10087 deal with safety separation distances and surrounding structures, such as dikes and curbs, that collect flammable liquids with a flash point below 200 °F (93.4°C). The code also limits the number of containers in a group, as depicted in Table 6.4.1.2. SANS 10087 has a similar requirement but includes a firewall if more than six vessels are used in the group.

Figure 7: Comparison between safety distances specified by NFPA58 and SANS 10087-3 for Groups of LPG containers.

Once again, some common rules apply in this comparison, but one standout is that SANS shows more detail on separation distances when you look at other fuels (Oxygen in particular). This eases the process by not jumping to different codes.

2.2.4 Maximum Number of Containers in a Group and their Separation Distances – NFPA 58 (From Code)

The table below was taken from page 33 of the NFPA 58 standards. The maximum number of above-ground containers in a group is limited by the type of fire protection provided. Each container has a size of 12,000 galloons (45m3 ) or more:

Figure 8: Table showing the maximum number of containers in a group and their separation distances.

2.2.5 NFPA 58 Container Separation Distances

The table below from page 32 of the NFPA 58 standard shows the separation distances between mounded, above-ground containers or between containers.

Figure 9: Table showing the storage container separation distances.

NFPA 58 contains no visual layouts, but the tables are easy to read.

2.2.6 SANS 10087-3:2008 Edition 4 Separation Distances

In the following section, you will find most of the SANS separation distance layouts and tables. This makes it much easier to find the information needed to ensure the correct standards are followed with your new plant layout.

Figure 10: Table showing the separation distances for: “adjacent containers, important buildings, groups of buildings or adjoining property that can be built upon.”

Figure 11: Depiction of the minimum separation distances of LPG vessels below 200 tonnes. A firewall with a resistance rating of at least 2 hours interrupts the line of sight between the unprotected (uninsulated) section of the containers. Sources include Liquefied flammable gases, flammable liquids and oxygen storage (Page 17, SANS 10087-3).

Figure 12: Depiction of a storage facility plant layout section, with recommended safety distances for above-ground combined fuel/gas facilities (Page 36, SANS 10087-3).

Figure 12.1 shows the recommended safety distances for gas ONLY fuel installations.

Figure 12.2: Continuation of Figure 12.1.

Figures 10 through 12 show that using SANS 10087-3 is more user-friendly. Whether you are designing a plant layout consisting of white products and LPG or only an LPG site, there are enough safety distances to do so.

Please remember to refer to the latest codes to ensure you comply with the rules and regulations. Although much does not change from version to version, applying good engineering practice to any design will still be advantageous.

3 Piping Installations

To ensure the safety of personnel and assets on site, careful planning should be taken into account when designing and installing piping correctly, using the recommended type of material following the standards and codes. This will reduce the piping’s failure during its life span/facility. NFPA 58 states that certain piping, either indoors or outdoors, has certain pressure requirements. SANS 10087 has a similar requirement but has an in-depth scope of the material that can be used compared to that of NFPA 58.

Figure 13: Comparison between NFPA58 and SANS 10087-3 regarding piping installation requirements.

The figure below is a continuation.

Figure 14: This is a continuation of Figure 13, which compares NFPA58 with SANS 10087-3 regarding piping installation requirements.

4 Road Tanker Loading

NFPA 58 standards and codes state that cargo tankers transporting flammable liquids must comply with federal DOT carrier safety regulations, including piping and fitments on the road tanker. The standards and codes also include certain safety measures to ensure that LPG is transported safely between the tanker and the container. SANS 10087 standards and codes only state that the tanker’s risk to the bulk storage facility must be addressed and that all truck tankers must carry powder fire extinguishers.

Figure 15: The Figure refers to the general design of an LPG transport tanker.

Figure 16: Comparison between NFPA58 and SANS 10087-3 regarding road tanker loading.

It is clear that NFPA 58, in this instance, has a more elaborate recommendation layout to follow compared to SANS 10087-3. SANS 10087-3 only refers to fire protection protocols, by indicating the hose reel etc. you will need to ensure safety (Figure 17).

Figure 17: SANS 10087-3 Fire protection details. Only firefighting recommendations are listed in the last row, and no mention is made of safety distances.

5 Rail Tanker Loading

Each code states the following about rail tanker loading (transfer between containers). Both SANS 10087 and NFPA 58 codes state that a qualified person must always be present during connection, filling and disconnect from the rail tankers to the store facilities.

Figure 18: Comparison between NFPA58 and SANS 10087-3 of rail tanker loading.

Figure 19: Typical design of a rail tanker loading.

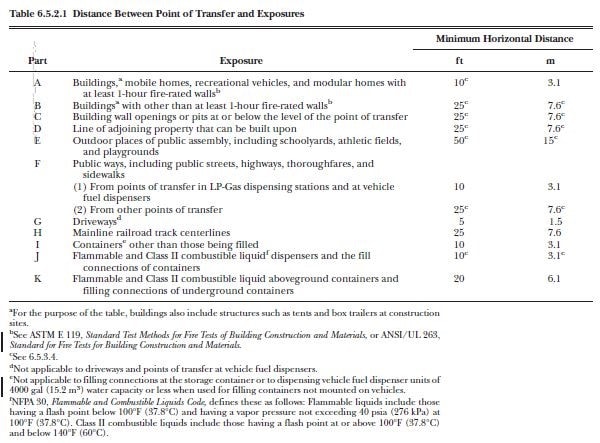

5.1 NFPA 58 – Distance Between Point of Transfer and Exposures

The table below was taken from page 34 of the NFPA 58 standard. It shows the point of transfer’s horizontal distances between containers and other buildings etc.

Figure 20: Indication of the safety distance from the transfer point and exposure area.

6 Conclusion

The original codes should still be read to form your opinion about correct engineering practice. Working with LPG can be dangerous, and to ensure the safety of the personnel on-site and the facility, the SANS and NFPA standards should be followed thoroughly before the bulk storage facility is designed.

The two compared codes and standards discussed in the article are NFPA (National Fire Protection Association) and SANS (South Africa National Standards). Both have similarities regarding the facility’s safety, but the separation distances in some departments could cause you to prefer one over the other. Using the codes and standards will not only help construct a safe bulk storage facility but will also assist with how it is utilized during its life span.

7 References

NFPA 58 – 2014 Edition

SANS 10087-3:2008 Edition 4

To all knowledge

To all knowledge