1 Introduction

The problem of oil sludge accumulation in storage tanks, pipelines, and processing equipment is not new in the petroleum industry. Engineers and scientists have been facing this problem since the discovery and large-scale production of petroleum products. Oil sludge cleaning is a mandatory prerequisite for clean and uninterrupted product supply. If not cleaned at regular intervals, this oil sludge will reduce the storage capacity of tanks, cause blockages in pipes, and accelerated corrosion. In petroleum industries, a large volume of petroleum products is stored in tanks. After some time, oil sludge accumulates at the bottom of these tanks. A continuous buildup of oil sludge affects the storage capacity of tanks and contributes to the increased impurity of petroleum products. To avoid these challenges, regular oil sludge treatment and removal is necessary for the petroleum industries. The cleaning process is carried out after scheduled inspections by using applied cleaning methods. This cleaning process can be manual, automatic, or by using robotic technologies depending on the type of tank is being considered for the cleaning process (Kardena, Hidayat, Nora, & Helmy, 2017)

Oil Sludge Accumulation at the Bottom of the Tank

1.1 Composition of sludge

Petroleum sludge combines several different concentrations of waste oil, gravel, other mineral particles, and water. The typical composition of oil sludge is 67% oil, 26% solids, and 7% water. During processing in the oil industry, thousands of ton of oil sludge is produced, which is not used as a byproduct by petroleum industries. When disposed of, this sludge can cause widespread environmental pollution. Oil sludge is categorized as hazardous waste and its handling and disposal is regulated by all the environmental protection agencies worldwide. That is why oil sludge cannot be discharged openly or disposed of in an open landfill. During the production of different petroleum products, oil sludge is accumulated at the bottom of the storage tanks, product tanks, in desalters, and the processing chambers of the reactors. If recoverable oil contents are less than 40 percent in the composition of the sludge, sludge cannot be used, and it requires disposal. Before their disposal, sludge needs different treatments to make their disposal environmentally friendly (Hahn & Loehr, 1992).

In petroleum industries, usually, the oil sludge contains greater than 40 percent of oil contents. Generally, more than one method is employed to separate its contents, including oil, water, and solid particles. In the treatment process, oil is separated from solid and water. Water and solids cannot be disposed of before treatment. For the treatment process, several methods are available, including thermal, mechanical, chemical, and biological. A combination of all these methods can also be used. Each of these methods has some advantages and disadvantages associated with the process discussed in this article (Chen et al., 2019).

2 Conventional methods of tank cleaning

Different methods are used to clean tanks in the petroleum industries to remove the oil sludge residues accumulated at the bottom. These methods can be used stand-alone or in combination with other techniques depending upon the composition of oil sludge. Following are some of the conventionally used cleaning methods (Liu, Liu, Liu, Zhang, & Ecology, 2019):

1. Centrifugation:

During centrifugation, oil sludge is drawn from the tank by high-speed rotating equipment. This equipment creates a strong centrifugal force to separate the elements of oil sludge depending on the density of each elementary particle. The whole process completes in a short period. Before centrifugation, a pre-treatment step can be introduced to reduce sludge density. Less viscous sludge requires less amount of energy during centrifugation. For pre-treatment of oil sludge, organic solvents and de-emulsifying agents are commonly used. Other methods such as the use of steam and direct heating can also be carried out. Centrifugation can reduce 92 to 96 percent of the oil sludge (AKINYEMI).

A typical centrifuging flowsheet

2. Solvent Extraction:

The solvent extraction process is used for cleaning oil sludge from storage tanks. It is an old method for oil sludge treatment and removal. In this process, a solvent is used to remove either non-volatile or semi-volatile components of oil sludge. The solvent extraction process is used within the storage tank to separate different parts of oil sludge, which makes it easier to clean the tank. Distillation is carried out to remove oil from the mixture. Usually, turpentine is used as a solvent in this process. As high as 50 percent of the oil can be recovered from the oil sludge using a solvent extraction process. Other readily used solvents are methyl ethyl ketone and liquified petroleum gas condensate. However, the recovery rate of these solvents is less than turpentine (Liu et al., 2019).

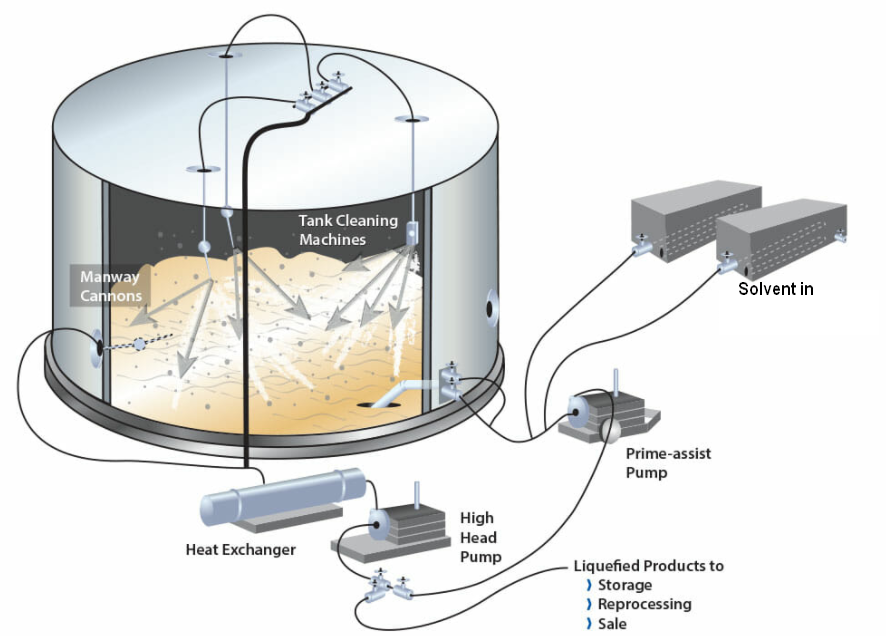

Solvent extraction flowsheet for tank cleaning

3. Biosurfactant Based Tank Cleaning:

Certain bacterial strains are used to produce biosurfactants for industrial use. These biosurfactants are grown on glucose and immiscible hydrocarbons as a source of active carbon base. This process has been tested on an industrial scale to produce several tons of active cultural having substantial biosurfactant bacterial growth. Biosurfactants are used as an alternative to chemical surfactants for the tank cleaning process. The cleaning process substantially cleans the bottom of the storage tank and removes a large amount of oil sludge. It also helps in the recovery of 90 percent of the hydrocarbons present in the oil sludge. The recovered hydrocarbons can be reused or sold after blending them with crude oil. (Jafarinejad, 2017).

4. Robotics Based Automatic Cleaning Method:

The conventional storage tank cleaning method has several disadvantages: poor safety, low efficiency, extensive time required in cleaning, and environmental challenges. In a robotics-based automatic tank cleaning system, a cleaning equipment system is used, including the robot, suction pump, hydraulic pump station, and remote control system. A narrow manhole is used to introduce the suction system inside the tank. The high-pressure water jet and mechanical shoveling are used to extract oil sludge from the bottom of the tank. This method has proved to be one of the most reliable cleaning methods. (Varjani et al., 2020).

5. Chemical and Heat Based Cleaning:

The process is an improved method of oil sludge cleaning from storage tanks. This process reduces the hazardous waste generated from the cleaning process and provides better hydrocarbon recovery. In this process, chemicals, water, heat, and process technology clean the tank. The oil sludge at the bottom contains high hydrocarbon contents, which is why their recovery is important. Chemicals, heat, and water are introduced into the tank to initiate the cleaning process. The process separates the components of sludge inside the tank that makes the tank cleaning easier (Z. Wang, Gong, Wang, Li, & Chu, 2021).

3 Biological Treatment of oil sludge

The biological treatment of oil sludge for tank cleaning is a comparatively new technique for treating oil sludge. In comparison to other available methods, biological treatments are cost-effective and require fewer procedural difficulties. Bioremediation is the most commonly used method (Cai et al., 2021).

3.1 Mechanism

When crude oil processing takes place in oil refineries, oil sludge is produced as a byproduct. The sludge is nonvolatile and stable at varying temperatures. It also shows less degree of biodegradability. The sludge accumulates at the bottom of the storage tank and gradually reduces the tank’s storage capacity. Oil sludge is a potential organic pollutant and carcinogen in nature. In bioremediation of the oil sludge, lab manufactured microorganisms like bacteria, fungi, algae, and plants are used to remove the harmful pollutants present in the oil sludge.

Microorganisms can remove toxic compounds from oil sludge by decomposing them in their guts. Microorganisms consume all the organic material present in the oil sludge and separate different components of the whole composition. They also help in the separation of any heavy metals present in the composition. To aid the bioremediation process, additives like fertilizers, compost, and bulking agents can be used (Q. Wang et al., 2018)(Ali et al., 2017).

3.2 Types of biological treatments

Different types of biological treatment methods are used in the Treatment of oil sludge. Following are some of the most commonly used biological treatment methods.

- Bioreactor method

In a bioreactor, a muddy container is used to treat oil sludge. The sludge is added to the container, where a nutrient medium is added. This process is also used in soil treatment where the soil is contaminated by petroleum products like diesel. A bioreactor is usually a glass container in which a temperature control mechanism is used. Temperature is generally controlled between 15 to 20 degrees Celsius to support the bacteria. In this process, within 45 days of Treatment, almost 90 percent of the degradation completes. This process is also coupled with other techniques like the application of electric fields to support bacterial degradation. This increases the efficiency of the overall process (Aljuboury, Palaniandy, Abdul Aziz, & Feroz, 2017).

- Bioaugmentation Method:

In the bioaugmentation method, efficient microbial inoculants are added to the sludge in soil. This helps in increasing the biodegradation rate of the oil sludge present in the mixture of hydrocarbons. Bioaugmentation is of two types, single bacteria strengthening and bacterial consortium strengthening (Pajoumshariati, Zare, & Bonakdarpour, 2017).

- Biological Flotation Method:

The biological floatation method is a comparatively new method for the Treatment of oil sludge. In this process, microorganisms produce gas that helps in the removal of oil. To produce results, the microorganism is placed in a mixture of a compound containing oils. The culture media is placed at a temperature where microorganisms can grow at the maximum rate. Effective removal of crude oil can be carried out at 40 degrees Celsius where 98 percent of the oil is removed. As this technology is currently under development stages, it cannot be used at large industrial scales (Mahdi, Aziz, & Eqab, 2017).

- Bioremediation:

In the bioremediation process, biological microorganisms or plants are used to treat oil sludge obtained from the industry. A specially cultured microorganism is cultured, including bacteria, algae, fungi, and plants that can absorb and digest heavy metals and separate oil from water base. Bioremediation can give a 75 to 80 percent separation result based on the quality of microorganism used (Ghimire & Wang, 2018).

3.3 Benefits

Biological Treatment of oil sludge offers a wide range of benefits over other treatment processes such as solvent extraction, freezing and thawing, and surfactant addition method. The primary benefit is that this process is cost-effective in its operation, and a high rate of recovery can be achieved with this technology. Secondly, as oil sludge treatment is carried out to prevent possible environmental degradation after the disposal of untreated sludge, biological Treatment offers a minimum possible impact on the environment. As the biological treatment process does not involve any additive or solvent at any stage except the addition of fertilizers, it does not produce any harm to the environment (Ali et al., 2019).

3.4 Limitations

The biological treatment process for oil sludge recovery has certain limitations as compared to other methods. As the biological treatment process involves active microorganisms in the Treatment, including fungi, algae, bacteria, and plants, they require several days or even weeks to show results. On the other hand, applied treatment methods are quick in operation.

The efficiency output of the biological treatment process is not reliable as it depends on the quality of the culture media in which microorganisms are grown. If proper temperature, humidity, and moisture are not provided to the microorganism, the digestion process cannot be completed successfully, leading to poor separation of oil and water from the sludge.

Another limitation in the biological treatment process is the requirement of space in the industry. For biological processes, separate testing labs and digestion chambers are needed compared to solvent extraction that can be carried out in the tank itself. It increases the construction and operation cost of the industry (Swathi, Muneeswari, Ramani, & Sekaran, 2020).

4 Cost comparisons

The cost of the biological treatment of oil sludge varies in different countries and the type of biological process used in the Treatment. Here, a comparison of three other biological treatment technologies is given. These technologies are bioreactor, biological flotation method, and bioremediation.

The analysis shows that bioreactor offers the least operational and maintenance cost while bioremediation provides the highest cost. Similarly, the cost per cubic meter during construction is also highest in bioremediation and lowers in a bioreactor. Many technological, legal and financial parameters are associated with the cost estimation of different biological treatment processes (Sarsaiya et al., 2019).

Operational Cost of Different Technologies

Cost Comparison Among Different Techniques

5 How It Is Environment Friendly?

In other applied techniques of tank cleaning like solvent extraction and surfactant techniques, many chemicals and solvents are used. In these processes, the use and recovery of these organic and inorganic solvents, in turn, becomes a hectic and energy-consuming task. Moreover, the use of solvents in such large volumes is a threat to the environment as these solvents cannot be discarded in the open environment (Chen et al., 2017).

On the other hand, the use of biological methods of cleaning such as bioremediation is an environment-friendly method, as it does not involve the use of any solvent for the cleaning procedure. The bacteria, algae, or plants used in this process are friendly to the environment and do not cause any biohazard to the environment. The use of fertilizers to enhance oil recovery is also environment friendly as it aids in improving the soil quality. Bioremediation also removes heavy metals from oil sludge. Heavy metals are responsible for serious soil quality degradation and are toxic to all kinds of living species.

The final products of the bioremediation are easy to dispose of in the environment, such as in planned landfill sites or underground disposal sites. Heavy metals and organic compounds separate by the bacteria under digestion can also be recovered in the process. Overall, bioremediation of oil sludge is one of the most environmentally friendly procedures used to carry out petroleum tank cleaning (Inglezakis et al., 2017).

6 Conclusions

Oil processing industries dealing in petroleum products have multiple oil storage tanks in their facilities. These storage tanks are filled with millions of barrels of oil each day. In these tanks, oil sludge accumulation is a common issue. Oil sludge is removed by several different applied methods to clean the tank. Among many physical and chemical processes of cleaning, the biological method of tank cleaning is the most environmentally friendly. As it requires less use of organic/inorganic compounds and ensures a greater percentage of oil recovery. However, to improve the process and efficiency, limitations need further research and development.

7 References

AKINYEMI, O. Recent Development on Biological Treatment of Oil Sludge from Petroleum Industry.

Ali, A. M., Abu-Hassan, M. A., Ibrahim, R. R., Zaini, M. A., Abdulkarim, B. I., Hussein, A. S., . . . Halim, M. A. I. M. (2017). Characterization of Petroleum Sludge from Refinery Industry Biological Wastewater Treatment Unit.

Ali, A. M., Hassan, M. A. A., Ibrahim, R. R., Jalil, A. A., Nayan, N. H. M., Abdulkarim, B. I., & Sabeen, A. H. J. J. o. E. C. E. (2019). Analysis of solid residue and flue gas from thermal plasma treatment of petroleum sludge. 7(4), 103207.

Aljuboury, D., Palaniandy, P., Abdul Aziz, H., & Feroz, S. J. G. N. J. (2017). Treatment of petroleum wastewater by conventional and new technologies-A review. 19, 439-452.

Cai, Y., Wang, R., Rao, P., Wu, B., Yan, L., Hu, L., . . . Health, P. (2021). Bioremediation of Petroleum Hydrocarbons Using Acinetobacter sp. SCYY-5 Isolated from Contaminated Oil Sludge: Strategy and Effectiveness Study. 18(2), 819.

Chen, C., Liang, J., Yoza, B. A., Li, Q. X., Zhan, Y., & Wang, Q. J. B. t. (2017). Evaluation of an up-flow anaerobic sludge bed (UASB) reactor containing diatomite and maifanite for the improved Treatment of petroleum wastewater. 243, 620-627.

Chen, C., Ming, J., Yoza, B. A., Liang, J., Li, Q. X., Guo, H., . . . Wang, Q. J. B. t. (2019). Characterization of aerobic granular sludge used for the Treatment of petroleum wastewater. 271, 353-359.

Ghimire, N., & Wang, S. (2018). Biological Treatment of petrochemical wastewater. In Petroleum Chemicals-Recent Insight (pp. 55-74): IntechOpen.

Hahn, W., & Loehr, R. (1992). Biological treatment of petroleum oily sludges. Paper presented at the Permian Basin Oil and Gas Recovery Conference.

Inglezakis, V., Malamis, S., Omirkhan, A., Nauruzbayeva, J., Makhtayeva, Z., Seidakhmetov, T., & Kudarova, A. J. J. o. e. m. (2017). Investigating the inhibitory effect of cyanide, phenol and 4-nitrophenol on the activated sludge process employed for the Treatment of petroleum wastewater. 203, 825-830.

Jafarinejad, S. J. C. I. (2017). Activated sludge combined with powdered activated carbon (PACT process) for the petroleum industry wastewater treatment: a review. 3(4), 368.

Kardena, E., Hidayat, S., Nora, S., & Helmy, Q. J. J. P. E. B. (2017). Biological Treatment of synthetic oilfield-produced water in activated sludge using a consortium of endogenous bacteria isolated from a tropical area. 8.

Liu, Y., Liu, Y., Liu, Z., Zhang, A. J. C., & Ecology. (2019). Strengthening effects of ammonia nitrogen on the harmless biological Treatment of oily sludge. 35(1), 20-35.

Mahdi, A. M. E., Aziz, H. A., & Eqab, E. S. (2017). Review on innovative techniques in oil sludge bioremediation. Paper presented at the AIP Conference Proceedings.

Pajoumshariati, S., Zare, N., & Bonakdarpour, B. J. J. o. M. S. (2017). Considering membrane sequencing batch reactors for the biological Treatment of petroleum refinery wastewaters. 523, 542-550.

Sarsaiya, S., Awasthi, S. K., Jain, A., Mishra, S., Jia, Q., Shu, F., . . . Awasthi, M. K. J. B. P. o. S. W. (2019). Recent Developments in the Treatment of Petroleum Hydrocarbon and Oily Sludge from the Petroleum Industry. 277.

Swathi, K., Muneeswari, R., Ramani, K., & Sekaran, G. J. B. (2020). Biodegradation of petroleum refining industry oil sludge by microbial-assisted biocarrier matrix: process optimization using response surface methodology. 31(4), 385-405.

Varjani, S., Joshi, R., Srivastava, V. K., Ngo, H. H., Guo, W. J. E. S., & Research, P. (2020). Treatment of wastewater from petroleum industry: current practices and perspectives. 27(22), 27172-27180.

Wang, Q., Liang, J., Zhan, Y., Yao, X., Liu, Z., Li, Q. X., . . . Biotechnology. (2018). Treatment of petroleum wastewater using an up‐flow anaerobic sludge blanket (UASB) reactor and turf soil as a support material. 93(11), 3317-3325.

Wang, Z., Gong, Z., Wang, Z., Li, X., & Chu, Z. J. E. E. R. (2021). Application and development of pyrolysis technology in petroleum oily sludge treatment. 26(1), 1-15.

To all knowledge

To all knowledge