1 Background

1.1 What is A Virtual Gas Pipeline?

The demand for cleaner energy pushes the consumption of natural gas higher and higher. Usually, in the European and North American continents, as well as the Russian Federation, the delivery of natural gas is through pipelines because they can easily reach customers from gas wells laid under the ground surface. However, gas pipeline delivery becomes technically impossible or economically not feasible for customers located on the other side of the ocean or far away from production wells. Converting the gas into a liquid form will be the easiest way to handle it.

The term virtual pipeline is one of the most used lately in the oil & gas environment; it means connecting consumers with multiple gas sources, exceeding the scope of conventional gas pipelines and providing energy in isolated regions. Scalable and modular virtual pipelines use shipping by road, train or ship to deliver the fuel to the end user. Through a regasification process, the LNG returns to its original gaseous state [1].

Figure 1. A typical LNG facility. Source: https://www.enestas.com/que-es-un-gasoducto-virtual-2/

The handling of imported Liquefied Natural Gas (LNG) requires a complete receiving terminal infrastructure to be available, from the jetty, the storage tanks, the regasification facility and the pipelines to transport the regasified natural gas. Usually, the LNG receiving terminals are close to the coast and customers, i.e., the populated metropolitans or gas-fired power plants. In some markets, if the liquefying facility is not available, then transporting natural gas in compressed conditions will be used. The compressed natural gas (CNG) will expand 100 times after release. Compared to the LNG, which can expand to 600 times, the transportation and logistic handling cost of CNG is higher.

Virtual pipelines are used for the distribution of LNG. This solution helps supplying natural gas to consumers in remote locations or far from the pipelines. The fuel is provided utilising cryogenic tanks or containers that allow natural gas to be hauled in a liquid state (at -162 °C), occupying a small space.

1.2 Is Gas Environmentally Friendly?

En un contexto de transición hacia el uso de energías más limpias, el Gas natural (GN) resulta ser un combustible adecuado para llevar acabo tal transición [2]; en ese sentido, el uso más intensivo de este combustible puede contribuir a la reducción de emisiones, frente a los combustibles derivados del petróleo, mientras se mejore la eficiencia de las energías renovables no convencionales.

Gas is a fluid that has two phases, a gaseous and a liquid, and this is achieved by modifying its pressure and/or temperature in one phase or another (thermodynamics). In the liquid phase, the gas reduces its volume by 600 times, which in the gas phase, facilitates its transport. Today technology allows it to play with thermodynamics in such a way that a gas obtained from the reservoir in the gas phase, once treated with low pressure, can modify its molecular structure and become liquid or vice versa by subjecting it to high-pressure returns from its liquid phase to its gas phase.

Natural gas is recognised worldwide as one of the most environmentally friendly energy sources due to its high calorific value and low emissions of air pollutants when combustion. It is the cleanest fossil fuel, given its composition based on gaseous hydrocarbons (mainly methane), and because it is odourless, colourless, non-toxic or corrosive, and evaporable at room temperature. Therefore, it does not pollute soil or water, and its combustion has very low emissions compared to other fuels of its kind [3].

Regarding emissions from its combustion, natural gas has substantially lower greenhouse gas emissions than other sources, such as coal and oil and their derivatives (gasoline, kerosene, etc.). Indeed, CO2 emissions are between 40 and 50% lower than those of coal and between 25 and 30% lower than those of fuel oil.

On the other hand, and taking into account its physical conditions, in a liquid state it reaches -160º Celsius which makes the main emerging risk is burning due to low temperature. In the event of a spill, the LNG is lighter than air, so the cloud that forms gas vapour rises rapidly and evaporates by mixing with the air. An explosion of a vessel with LNG is highly unlikely since igniting a liquid at -160 degrees Celsius requires a source of heat energy that cannot be easily reached.

1.3 Main Benefits

When the characteristics of the terrain, the distances or the absence of large consumption centres make the laying of conventional gas pipelines unfeasible, the trailers of the Virtual Gas Pipeline connect consumers without access to infrastructure with the last mile of the gas network, the deposits themselves or biodigesters. This way, it is possible to establish distribution networks that enhance the range of gas sources in radii of up to hundreds of km, taking advantage of the existing road network.

The efficiency of the Virtual Gas Pipeline surpasses other road gas transport alternatives [4]. Unlike traditional tube trailers, their VST trailers fractionate their compressed natural gas (CNG) cargo into 1000-1500 Nm3 containers that can be distributed unitarily. This configuration allows each consumption centre to receive the number of containers according to the daily demand for gas and eliminates the costs of transporting unnecessary surpluses.

Continuous and monitored supply

Monitored 24/7, the Virtual Gas Pipeline replicates the same supply conditions as a direct connection to the public gas network. Each time the container meter indicates a drop in load levels, the system receives an automatic replenishment order.

Scalability and reduced operating costs

The modularity of each stage of the Virtual Pipeline allows the system to increase its capacity at the rate demand does without increasing the incidence of investment or operating costs.

Integration into the system of new gas sources

Natural gas producers can use the Virtual Gas Pipeline to reach consumers directly in the oil industry. This makes exploiting wells outside the system profitable due to their maturity or dispersion in large territories. Also, to reduce the necessary investment in gathering operations carried out under these conditions. In the case of agricultural-livestock producers, the Virtual Gas Pipeline can be used to monetise biogas production from biodigesters.

Savings and access to clean fuel

The Virtual Gas Pipeline allows to replacement of the consumption of traditional fuels, such as gasoline, diesel, fuel oil and LPG, among others. The change reduces pollution and generates savings in fuel costs.

2 SOFC & Re-Gasification Systems

2.1 Introduction

SOFC uses natural gas as the feedstock to generate electricity through a series of chemical reactions. Unlike the conventional gas firing techniques, which burn gas to create a high-pressure hot air flow and then push the turbine to turn. In some advanced gas firing systems, the residual heat from the gas turbine is used to heat water creating high-pressure steam to turn a second-stage steam turbine. It’s called CCGT (Combined Cycle Gas Turbine).

The efficiency of CCGT can reach as high as 50-55%. However, the SOFC efficiency is higher than the traditional gas firing techniques or the CCGT. The total conversion efficiency of SOFC is around 85-90%, while the conversion efficiency of electricity can reach 60-65%. It means the generation cost is lower for power only or combined heat & power. Generation capacity could be flexibly configured, modularly designed and implemented from several kW for residential applications to mega Watt power plant applications. As a result, no huge capital investment upfront, no ample land space is needed, nor a lengthy construction period is required.

In some areas where the connection to the national electricity grid is not possible or feasible, but the delivery of LNG is manageable. Adopting this SOFC energy supply system becomes a practical and economical solution. Inland, small villages, tribes, and communities without electricity coverage, but the LNG is deliverable through railway, highway, or waterway are also ideal candidates for this system.

Using SOFC to generate electricity is considered the best way to offer baseload stability in a distributed generation electricity network when other generation devices are also connected, such as solar and wind power. The advantage of SOFC is that it’s cleaner, has higher efficiency, affordable cost and is easy to move.

2.2 System Description

After an LNG vessel reaches the receiving port, the cargo will first be unloaded into the storage tank. When customers request natural gas delivery, the fluid will move down through the pipeline network to each demand site. Before pumping in the pipeline, the liquefied natural gas (LNG) will go through vaporisation to recover the gaseous state. The widespread LNG vaporiser systems include ambient air, open-rack (using seawater), submerged combustion, and intermediate fluid vaporisers. The regasification process will need available spaces and an external amount of energy.

A Solid Oxide Fuel Cell (SOFC) takes hydro-carbonate fuel as feedstock, such as natural gas (methane), and goes through a series of chemical processes (not burning), then generates electricity with high conversion efficiency plus some high-quality heat. Using the heat for LNG regasification and forming a close-loop energy supply system becomes very attractive in terms of compactness, economy and ease of operation. Especially for those remote communities, rural areas, and remote islands, energy access is usually not available. The combination of SOFC and regasification modules will perfect the downstream operation in the natural gas value chain.

The handling of imported LNG requires a complete receiving terminal infrastructure to be available, from the jetty, the storage tanks, the regasification facility and the pipelines to transport the regasified natural gas. Usually, the LNG receiving terminals are close to the coast and customers, i.e., the populated metropolitans or gas-fired power plants.

In some markets, if the liquefying facility is not available, then transporting natural gas in compressed conditions will be used. The compressed natural gas (CNG) will expand 100 times after release. Compared to the LNG, which can expand 600 times, CNG’s transportation and logistic handling cost are higher [5].

2.3 Operational Path

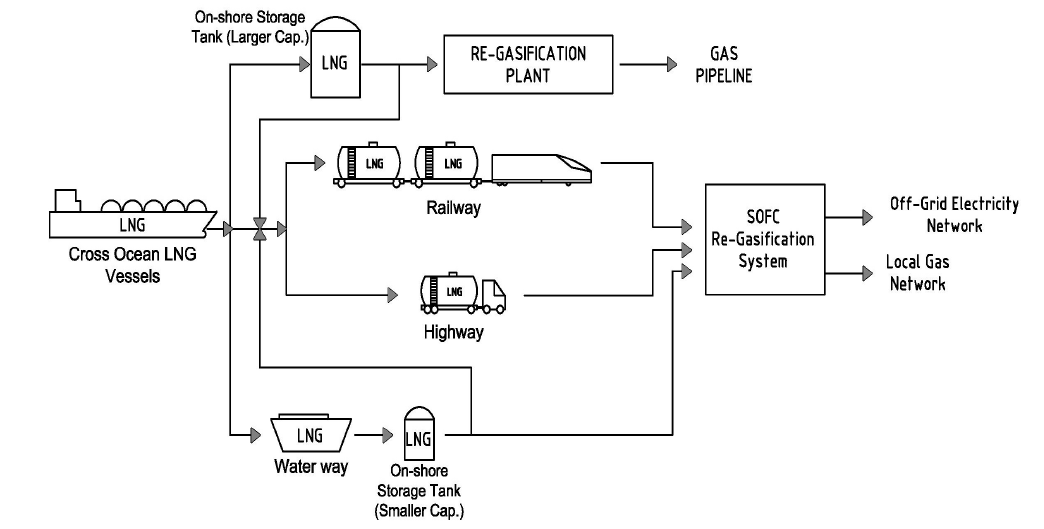

The whole micro-grid energy generation system structure is based on the SOFC as the key to providing electricity and gas after regasification from the LNG. The LNG is transported to the site by LNG carriers, land trucks or railway cars. A diagram of the operational pattern is shown in Figure .

Figure 2. SOFC regasification operation system diagram. Source: https://iopscience.iop.org/article/10.1149/09601.0121ecst

The portable cryogenic tanks are connected to a SOFC regasification unit in either single or multiple tank arrangements. The vaporisation chamber connected will have an electric heater installed on the bottom to heat the water only when additional heat is required, then pump the heated water to the top and rinse it down through the LNG coils. A heater coil or plat surrounds that LNG pipe to provide more heat. There will be a hot air blower in the lower position to blow up the hot air to the LNG pipe.

The hot air is coming from the exhaust opening of the SOFC. Normally, the exhaust air temperature from the SOFC hot box is around 200 °C. The water will be heated by the SOFC’s heat exchanger. With the 25-40% conversion efficiency allocated for heat, the heat will be directed into a hot water reservoir to rinse the LNG pipe in the vaporisation chamber. In some cases, the more natural gas output is required, the more extra heat will come from the electric heater embedded at the bottom of the hot water reservoir. The electricity is from the output of SOFC. The whole operation algorithm is under the control of a microcomputer.

The output of the regasification unit is connected to a gas compressor unit, which presses the natural gas into the pipeline and delivers it to customers. Plus, a portion of gas will flow into the adjacent SOFC unit as feedstock to generate electricity and heat for the whole station. The output natural gas pressure is monitored and controlled by the station control computer. Control devices include the LNG flow rate, the exhaust hot air flow rate, the hot water rinse rate, the heat exchange level, the heater temperature and the SOFC’s gas in-flow rate … etc.

3 Why Are Virtual Pipelines Becoming a Reality?

3.1 A Sustainable Fuel Alternative

Virtual Pipelines are seen as an alternative to promote the use of NG since this mode of transport allows to link to supply and demand in a shorter time because it does not require the construction of a physical pipeline; in addition, it is more flexible as the starting and arrival points can be modified and show better adaptability to changes in demand. While it is true that the term “Virtual Gas Pipelines” is recent, this form of NG transport already existed, although on a smaller scale and only applied to the transport of Compressed Natural Gas (CNG) to Vehicular Natural Gas (VNG) sales stations and distant industries or not connected to an NG pipeline.

It is in recent years that you can see a growing trend in the development of these larger-scale projects that try to supply the same types of customers as a conventional gas pipeline system; largely due to the technological improvements that have made it possible to reduce the costs of this type of transport alternative.

Given the current importance of the topic, this section makes, in the first part, a description of the value chain related to virtual gas pipelines under the two current modalities: CNG and LNG. Then, a comparative economic analysis is carried out between Virtual and conventional Gas Pipelines; in that sense, an isocost curve is constructed and determines the best of the two options according to each demand/distance combination.

3.2 Value Chain

A virtual gas pipeline is a system that makes possible the land, sea and river transport of compressed natural gas (CNG) and liquefied natural gas (LNG) to places where there are no conventional pipeline networks through the use of tanker trucks and LNG tankers. [6]. Although there is also a looser definition by the company Galileo S.A. that tells us that a Virtual Gas Pipeline consists of the transport and distribution of NG from any gas source to any point where there is a need for hydrocarbon.

It should be noted that both definitions do not consider economic and geographical factors that justify the existence of this NG supply technology. For example, there are distances from the fact that a conventional pipeline ceases to be economically viable or other geographical restrictions that will make it impossible for specific populations to access the NG in a conventional way.

Depending on the modality under which NG, CNG or LNG is transported, the value chain of a virtual gas pipeline varies in the requirement of certain facilities. Next, the processes of both technologies are developed.

For a CNG virtual pipeline, the process begins with the compression of the NG within the transport modules. Then, specially conditioned trailers perform the road transport of the modules at average speeds for cargo transport. Finally, when they reach the point of consumption, the modules are downloaded on platforms. After passing through a reduction station, the modules are ultimately connected to the domestic or industrial supply network.

The LNG transport process comprises three stages from the collection of natural gas to the consumer market, which are: Liquefaction, where the NG is filtered, dried and cooled; the transport system, which is made by means of trucks equipped with cryogenic tanks; finally, the Regasification process, where the liquid is converted back into gas.

As can be seen, the main difference between both modes of transport is the infrastructure required: in the case of the CNG mode, a compression and decompression station is needed, while when the transfer is low, LNG, liquefaction and regasification stations are required. The remaining infrastructure required in both cases is virtually the same.

3.3 Virtual vs Physical Gas Pipelines from an Economic Perspective

The amount of NG demand and the distance between the point of supply and distribution of the NG shape the cost of each transport alternative and are important axes of a decision on which of them is the most efficient economically.

Several studies indicate that opting for physical pipelines is more convenient when there are high levels of demand compared to the distance to the requesting locality; CNG is when demand and distance are small, and LNG is over long transport distances compared to the required demand.

However, can the question be asked whether there are combinations of distances and demand for which, in terms of costs, two indifferent alternatives are? Building a line that encompasses such points can be very useful in deciding, depending on the location and potential demand of a locality, how to supply it with GN. Such an exercise is performed below.

Pipelines transport natural gas in the gaseous form, being of the “point-to-point” type. The operation is simple and secure, involving a small number of connections. The main physical characteristics of gas pipelines are internal diameter, the thickness of the pipeline wall, and distance or extension. Along the extension, automatic blocking valves are installed, with spacing determined by the standards (for example, a blocking valve every 15 km, approximately) to block the pipeline in case of breakage and maintenance. Some argue that the cost of investment in the pipes represents 90% of the total [7].

The main variables of the gas pipelines are diameter, operating pressure, distance and terrain. Other factors, such as weather, labour costs, population density, and passing rights, can affect construction costs significantly. However, the final cost is affected by numerous factors, but that does not mean that it is impossible to make a general estimate of what a pipeline may cost.

The World Bank publishes a rule it calls Rule-of-Thumb, in which it offers an initial estimate that associates only two variables, diameter and distance. According to this rule, the cost is between 15 and 30 dollars for each inch of diameter and each meter of length, recommending even using 20 dollars for a first calculation; you can also reference the cost of gas pipelines recently built.

Based mainly on the information obtained from representatives of GALILEO (Argentina), NEOgás (Brazil) and FIBA (USA) that own the CNG system; the information of GásLocal (Brazil, consortium formed by White Martins, Petrobras and GásLocal itself) that own the LNG system and the unit costs per kilometre-inch for the construction of a gas pipeline proceeded to make the quotations of the equipment, including investment, facilities and operation & maintenance costs.

The cost of transport logistics begins with estimating the lifting of the number of trucks for the modal CNG and LNG needed to serve each combination of volume and distance. In this way, a model was developed to cover the logistical considerations related to these costs.

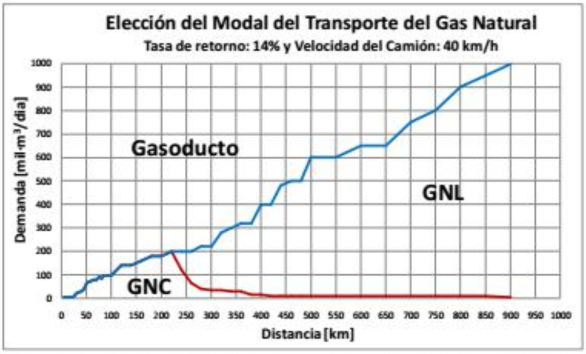

Figure 3. Effect of distance on the choice of modal for a given NG demand.

Assuming a demand of 100,000 m3 / day, the number of CNG trucks increases rapidly with the distance travelled, while the growth of LNG carts occurs more slowly. This is due to the energy density of LNG compared to CNG.

Making a graph where you can choose the best transport modal given the demand for NG and the distance travelled is the objective of this section; however, there are sensitivities among the most important, the average speed of the truck in the section travelled and rate of return that were analysed. It is worth remembering all this for the technical and economic premises established in this work to make the comparison.

In Figure , for a return rate of 14% and trucks travelling at the average speed of 40km/h, it presents situations where modal data results in a lower cost of transporting the NG, depending on the distance and demand. It was observed that the use of gas pipelines is justified in cases of high demand. For distances above 250km, LNG is highly competitive. CNG is attractive only for low demands and small distances, although this modal requires lower investment and operational costs for short distances.

We have to mention that the introduction of natural gas is assured when the price of gas, including the price at the entrance (source), plus transport, plus the cost of transportation of the modal, plus the distribution rate is lower than the price of replaceable energy. That is, it is necessary to evaluate each case, particularly the market to be supplied, to know if it has economic viability to develop the project of the chosen modal.

4 Virtual Pipeline Applications

4.1 Argentina

In Catamarca, Galileo supplies 100,000 m3 of gas to Minera del Altiplano using VST units. The VST unit receives compressed gas, still in the gas phase, in containers inside bottles of gas stowed and interconnected for consumption. This easy-to-transport container allows a simple replacement for a full one. The other model of virtual gas pipeline is the one that the same company, Galileo Technologies, has developed to provide LNG to the Francisco I Ferry, which sails daily between Buenos Aires and Montevideo and, at the time, was the fastest ship in the world to use LNG as fuel.

Figure 4. Ferry Francisco I, the first high-speed vessel to use LNG as fuel. Source: https://www.buquebus.com/static/landings/brochure/#buquebus

In the case of the Francisco I Ferry, Galileo Technologies installed a plant in San Vicente with several modules of its liquefaction system. It takes natural gas from a pipeline, liquefies it in its modules and transports it in special trucks to the port of Buenos Aires, where it supplies LNG to the vessel. The system stands out for its simplicity and, in turn, for the economy since the trucks also use LNG as fuel [8].

4.2 Ghana

There are several similar projects in the world that incorporate other elements into the logistics chain. Norgas Carriers AS, a Norwegian shipping company of the Kistefos Group, in which I serve as Maritime Operations and Fleet Manager, has developed the concept to supply LNG to power plants, mines and emerging markets in West Africa. Ships load into offshore terminals and transport the LNG to emerging markets where it can be unloaded for regasification or storage barges or trucks transporting the gas to their end users. These markets are called Small Scale because the volumes required are less than any project of magnitude.

In this concept, the gas transported by ships is unloaded in the port of Tema to trucks of the ISOTank type, which transport around 35 m3 of LNG each. These trucks travel by road about 15 km from a densely populated area (there are no gas pipelines that link the port with the power plant) and unload into storage tanks installed together with the vaporisers in the power plant. In this way, the LNG already regasified in the vaporisers (returned to its gas phase) is used as fuel for a boiler that generates steam to move a turbine that ultimately generates electricity uploaded to the national electricity grid for consumption.

Another small-scale virtual pipeline project is marching on to supply gas to Sunon-Asogli and Trojan power plants. It would comprise seventeen ‘52-cubic-metre’ LNG trucks ferrying fuel from small ships berthed at the Tema port; eight trucks at the loading gantry at a time, and another eight trucks moving every night to deliver the commodity to the 560 MW gas-fired Sunon-Asogli Power Plant thermal plants. Loading is estimated to take an average of an hour. The initial contract quantity is said to be 60 MMscfd.

The source of LNG for the small-scale project is the LNG2Africa initiative, an Equatorial Guinea initiative to sell small-scale LNG for utilisation in Africa [9].

4.3 Borneo

Sabah Energy Corporation Sdn. Bhd. (SEC) supply natural gas to distant industrial and geographically scattered consumers using Virtual Pipeline technology. It can distribute natural gas within a 70 km radius of Kota Kinabalu Industrial Park (KKIP) on the northwest coast of Borneo. While the elevated costs of laying underground pipelines prevented SEC from distributing natural gas within the inlands of Sabah, Virtual Pipeline enables it to offer it cost-effectively, just as CNG does.

As a system, the pipeline involves three stages before meeting the distribution to its end users through a direct connection or a local distribution grid. These three stages are CNG compression, transport and pressure regulation. Additionally, the whole operation is remotely monitored in real-time through a SCADA system for proper management.

In its design, Sabah’s Virtual Pipeline operation launches in the KKIP with a CNG compression process. This compression process can reach a pressure of up to 250 bar thanks to advanced units that work as mother stations. Then, CNG is distributed on modular containers transported by road on specifically designed trailers to the daughter stations located in four different spots. Upon arrival at the consumption point, the easy-to-operate trailers’ mechanism unloads the necessary, filled modules and loads the empty ones. The truck continues its route to the next daughter station.

As part of the system’s adaptation capability according to the existing demand of each of the daughter stations, all modules are connected to Pressure Regulating Plants which supply natural gas at a suitable range of outlet pressure and flow requested by its final users.

Unlike traditional tube trailers, advanced modules can be exchanged even if the gas has not yet petered out at the consumption points, thus, avoiding transport waiting times. Once the truck has exchanged all its modules with the empty ones along its route, it returns to the mother station to restart the cycle. This ensures a permanent and suitable gas supply according to the consumption demand. It also enables scalability for optimal sizing to strike a perfect balance between operating and investment costs.

Working with modules allows the system to increase its capacity at the pace of demand, which makes Virtual Pipeline the most suitable solution for one of the fastest-growing regions in Malaysia, especially when there is a powerful driver to do it in compliance with environmental protection since Kota Kinabalu is a popular gateway for travellers visiting rainforest areas in Sabah and Borneo.

4.4 Bulgaria

It is the largest European project for massifying gas other than conventional gas pipelines. In the province of Plovdiv, CNG Maritza transports the NG by trucks to 13 municipalities, where it serves approximately 100 thousand inhabitants. CNG transport is sent from compressor packages to the modular MAT containers, where it is stored for further distribution.

Figure 5. MATs distribution routes across Bulgaria. Source: https://www.galileoar.com/en/historias/galileos-virtual-pipeline-improves-quality-of-life-in-bulgaria-2/

The shipments depart from the mother station of Graf Ignatievo, where 3 CNG compressors connected to the network that supplies this city reduce the volume of natural gas and provide 150,000 normal cubic meters per day (Nm3 / d). The trucks are then loaded and follow the routes of the virtual pipeline; the supply is permanent and continuous, which means that in case the CNG meter of the MAT indicates that the gas is about to be finished, the daughter stations automatically request a replacement. In addition, the entire stage of the circuit is monitored 24 hours a day by a SCADA System.

Currently, the company has 6 VST trailers with a daily distribution capacity of 80 MATs (120 thousand Nm3 of GN). The arrival of NG in these areas has allowed industries to replace diesel consumption with NG as a production input. Likewise, businesses and homes have changed similarly to cover their heating needs [10].

5 References

[1] https://www.naturalgasintel.com/virtual-pipeline/

[2] https://www.iea.org/reports/world-energy-outlook-2017

[3] https://group.met.com/en/mind-the-fyouture/mindthefyouture/

[4] https://www.galileoar.com/www-gasoductovirtual-com/

[5] Ling-yuan Tseng 2020 Virtual Pipeline System ECS Trans. 96 121

[6] Reporte De Análisis Económico Sectorial Sector Gas Natural Gasoductos Virtuales: una nueva alternativa para intensificar el uso del Gas Natural en el país Año 7 – N°10 – Diciembre 2018

[7] López, M. A.(2010). Evaluación técnico-económica de las alternativas tecnológicas de transporte de gas natural. gn: Revista de gas natural. Volumen: 1. (pp. 18 – 26).

[8] https://confluenciaportuaria.com/destacada/el-concepto-del-gasoducto-virtual-y-su-aplicacion-practica-en-argentina/

[9] Okyere, Mavis. (2019). OUTLINE OF GHANA’S LNG STRATEGY: DEMAND, PRICE AND PROJECTS.

[10] https://www.ngvglobal.com/blog/galileo-technology-provides-fuel-alternative-for-bulgarias-off-pipeline-regions-0409

To all knowledge

To all knowledge